Groundsmaster 4010--D Operator CabPage 9 -- 11

CAUTION

The air conditioning system is under high pres-

sure. Do not loosen any system fitting or compo-

nent until after the system has been completely

discharged by a certified A/C service technician.

5. Have refrigerant evacuated from air conditioning

system by a certified A/C service technician.

6. Label and remove hoses from heater core, evapora-

tor and drier--receiver. Immediately cap hoses and fit-

tings to prevent moisture and contaminants from

entering the system.

7. Loosen hose clamp that secures air duct hose to

heater/evaporator assembly covers. Slide hose from

covers.

8. Remove screws thatsecure top coverto bottom c ov-

er. Remove top cover to access heater/evaporator as-

sembly.

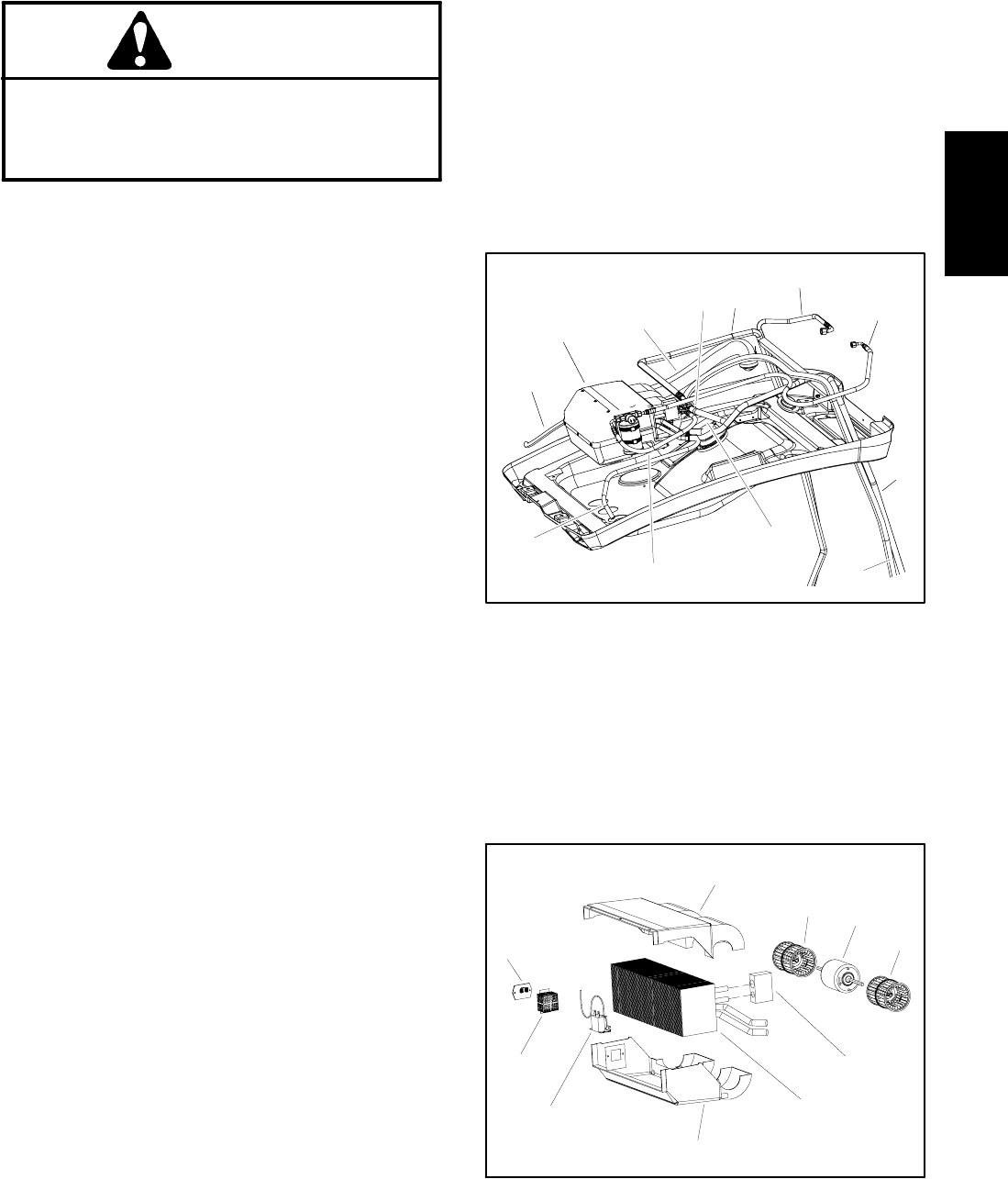

9. Disassembleheater/evaporatorassembly using Fig.

9 as a guide.

NOTE: Thereplacement of the drier--receiver is recom-

mended whenever the air conditioning system is

opened.

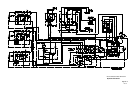

Installation (Fig. 7)

1. Assemble heater/evaporator assembly using Fig. 9

as a guide. Make sure that expansion v alve is covered

with insulating tape to prevent condensation issues.

2. Position heater/evaporator assembly into bottom

cover in headliner. Secure top cover to bottom cover

with removed screws.

3. Slide air duct hose ontoheater/evaporator assembly

covers and secure with hose c lamp.

4. Remove caps that were placed on hoses and fittings

during the removal process. Using labels placed during

removal, properly secure hoses to heater core, evapo-

rator and drier--receiver.

5. Make sure that condensation hoses are secured to

bottom housing of heater/evaporator assembly and are

routed to cab frame for proper draining of condensate.

6. Connect wire harness connectors to fan motor and

binary switch on drier--receiver.

7. Make sure that all machine air conditioning compo-

nents are installed and secure.

8. Have a certified air conditioning service technician

evacuate the air conditioning system completely, prop-

erly recharge the system with R134a refrigerant and

then leak test the system. A/C system capacity is 1.25

pounds of R134a refrigerant.

9. Operate the heater system to make sure that no en-

gine coolant leaks exist.

10.Lower and secure roof assembly (see Roof Assem-

bly Installation in this section).

1. Heater/evaporator assembly

2. Heater valve

3. A/C hose: evaporator to compressor

4. Air duct hose

5. A/C hose: compressor to condenser

6. A/C hose: condenser to drier

7. Heater hose: thermostat to heater valve

8. Heater hose: heater core to water pump

9. Heater hose: heater valve to heater core

10. Condensation drain hose (2 used)

11. A/C hose: drier to evaporator

Figure 8

2

1

3

4

7

8

6

5

9

10

11

10

1. Fan motor

2. Blower wheel

3. Heater/evaporator core

4. Expansion valve

5. Freeze switch

6. Resistor guard

7. Bottom housing

8. Top housing

9. Resistor

Figure 9

2

1

3

4

7

8

6

5

9

2

Operator

Cab