Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 135

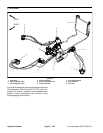

Removal (Fig. 106)

1. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

2. To prevent contamination of hydraulic system during

manifold removal, thoroughly clean exterior of PTO

manifold and fittings.

3. Disconnect wire harness connector from the sole-

noid valve coil on the PTO manifold.

4. Disconnect hydraulic lines from manifold and put

caps or plugs on open hydraulic lines and fittings. Label

disconnected hydraulic lines for proper installation.

5. Remove PTO manifold from the frame using Figure

106 as a guide.

NOTE: The upper cap screw on the right side PTO

manifold also secures the ground cable and has a lock

washer to ensure a good grounding path. Make sure

that lock washer is retrieved when removing RH PTO

manifold from frame.

6. If hydraulic fittings are to be removed from manifold,

mark fitting orientation to allow correct assembly. Re-

move fittings from manifold and discard O--rings.

Installation (Fig. 106)

1. If fittings were removed from manifold, lubricate and

place new O--rings onto fittings. Install fittings into man-

ifold openings using marks made during the removal

process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter).

2. Install PTO manifold to the frame using Figure 106

as a guide.

NOTE: Make sure that lock washer and ground cable

are positioned under uppercap screwhead wheninstal-

ling RH PTO manifold.

3. Remove caps and plugs from fittings and hoses. Us-

ing labels placed during manifold removal, properly con-

necthydraulic lines to manifold (see Hydraulic Hose and

Tube Installation in the General Information section of

this chapter).

4. Connect wire harness connector to the solenoid

valve coil on the PTO manifold.

5. Make sure hydraulic tankis full. Add correctoil if nec-

essary before returning machine to service.

Hydraulic

System