Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 111

Removal (Fig. 82)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

3. To prevent contamination of hydraulic system during

steering c ontrol valve removal, thoroughly clean exteri-

or of control valve and fittings.

NOTE: To ease installation, label the hydraulic lines to

show their correct position on the steering control valve.

4. Remove hydraulic lines from steering control valve.

5. Remove steering control valve from machine using

Figure 82 as a guide.

6. If hydraulic fittings are to be removed from steering

control valve, mark fitting orientation to allow correct as-

sembly.Remove fittings from valveand discard O--rings

(Fig. 83 or 84).

Installation (Fig. 82)

1. If fittings were removed from steering control valve,

lubricate and place new O--rings onto fittings. Install fit-

tings into port openings using marks made during there-

moval process to properly orientate fittings (Fig. 83 or

84). Tighten fittings (see Hydraulic Fitting Installation in

the General Information section of this chapter).

2. Install steering control valve using Figure 82 as a

guide.

3. Using labels placed during steering control valve re-

moval, properly install hydraulic lines to control valve

(see Hydraulic Hose and Tube Installation in the Gener-

al Information section of this chapter).

4. Make sure hydraulic tank is full.

5. Properly fill hydraulic system (see Charge Hydraulic

System in this section).

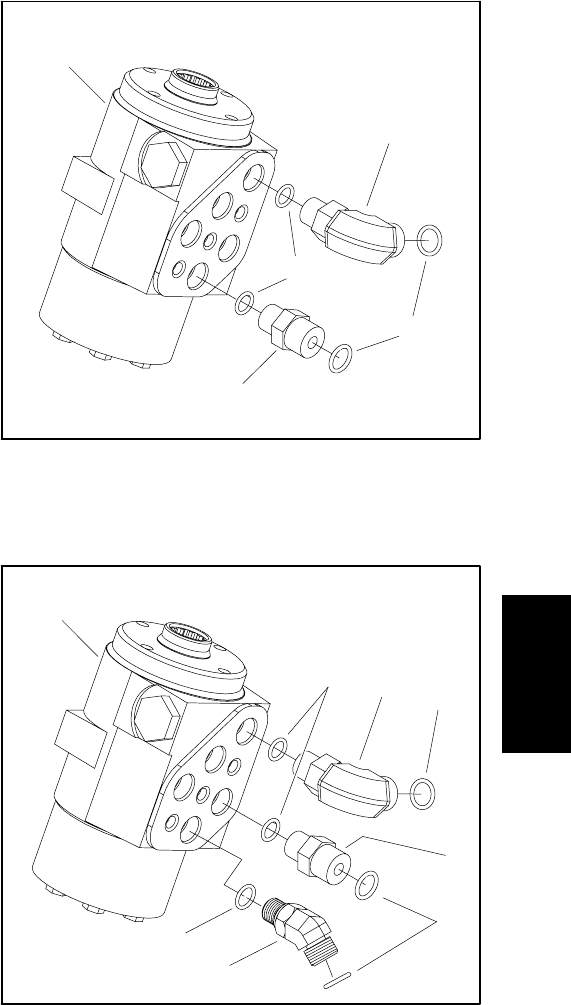

1. Steering control valve

2. O--ring

3. 90

o

hydraulic fitting

4. O--ring

5. Straight fitting (4 used)

Figure 83

1

2

4

5

3

GROUNDSMASTER 4000--D

1. Steering control valve

2. O--ring

3. 90

o

hydraulic fitting

4. O--ring

5. Straight fitting (3 used)

6. 45

o

hydraulic fitting

Figure 84

1

2

4

5

3

GROUNDSMASTER 4010--D

4

2

6

Hydraulic

System