Groundsmaster 4000--D/4010--DPage 5 -- 44Electrical System

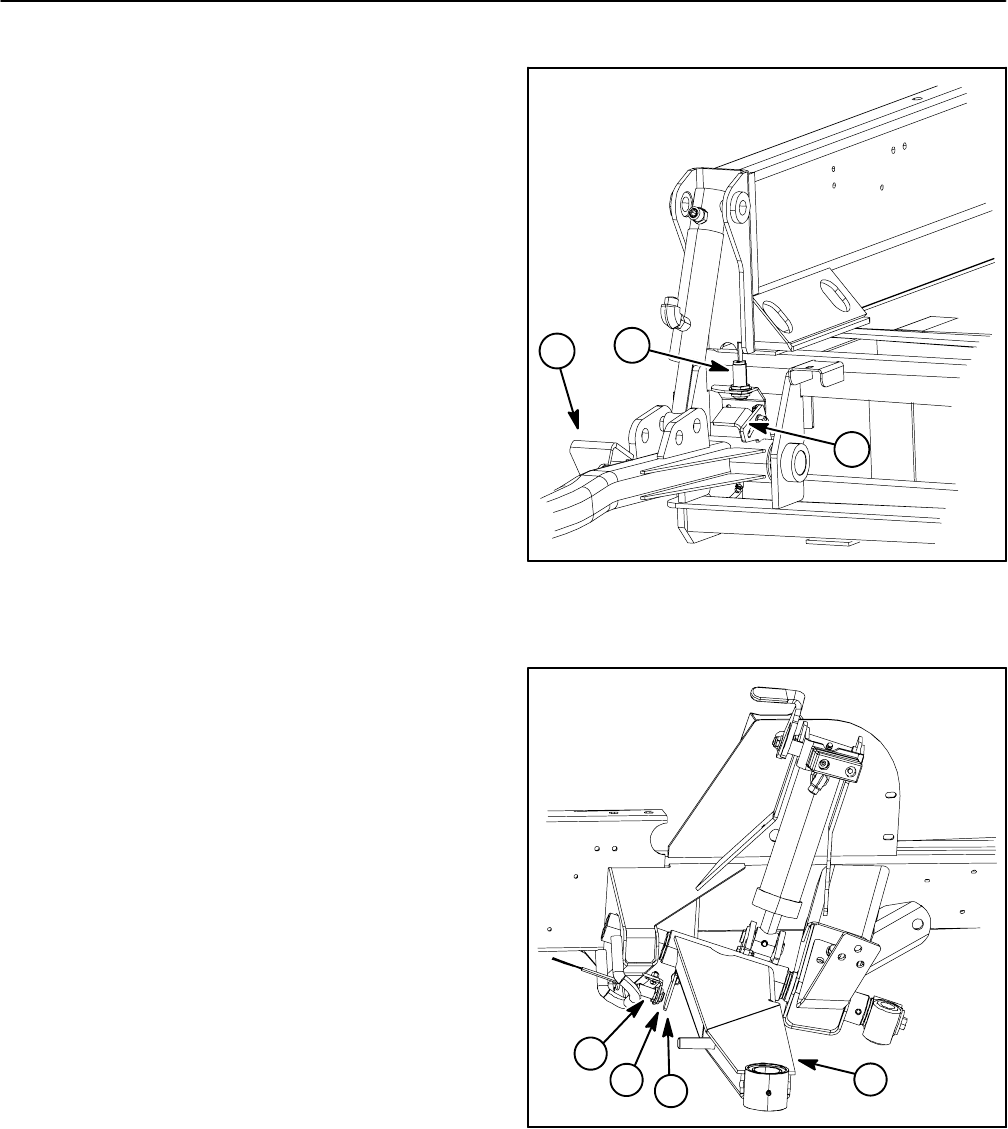

Cutting Deck Position Switches

Three (3) cutting deck position switches are used on the

Groundsmaster 4000--D and 4010--D. These switches

are located on the traction unit frame (Figs. 59 and 60).

The position switches are powered proximity switches

that incorporate an internal reed switch and a LED. The

deck position switches are used as inputs for the

TEC--5001 controller to prevent deck operation when a

cutting deck is raised. The switch sensing plates are at-

tached to the cutting deck lift arms. The position

switches for front and side decks are different.

The single front cutting deck position s witch is a normal-

ly closed switch. When the front cutting deck is lowered,

the sensing plateon the lift armis awayfrom the position

switch so theswitch is inits normally closedstate. When

the front cutting deck is raised, the sensing plate is

moved near the position switch and the switch opens.

The two (2) side cutting deck position switches are nor-

mally open switches. When a side cutting deck is low-

ered, the sensingplate on the lift arm is near the position

switch and the switch closes. When a s ide cutting deck

is raised, the sensing plate is movedaway from the posi-

tion switch so the switch is in its normally open state.

Testing

1. The cutting deck position switches and their circuit

wiring should be tested as a TEC--5001 input with the

Diagnostic Display (see Diagnostic Display in the Trou-

bleshooting section of this chapter). If the Diagnostic

Display verifies that the position switches and circuit wir-

ing are functioning correctly, no further switch testing is

necessary. If, however, the Display determines that a

positionswitchandcircuit wiring are not functioning cor-

rectly, proceed with test.

2. Park machine on a level surface, lower cutting

decks, stop engine and apply parking brake.

3. Turn ignition switch to the ON position (do not start

engine) and check LED on cable end of position

switches (Fig. 61). Switch LED should be illuminated

when the cutting decks are fully lowered.

4. Start engine, fully raise cutting decks and then stop

engine. Then, turn ignition switch to the ON position (do

notstartengine) and check LED on cableend ofposition

switches. Switch LED should not be illuminated when

the cutting decks are fully raised.

5. If a position switch LED did not function correctly:

A. Position cutting deck so sensing plate on the lift

arm is near the position switch (front cutting deck

raised and side cutting decks lowered).

1. Front lift arm (lowered)

2. Position switch

3. Sensing plate

Figure 59

3

1

2

1. Side lift arm (LH shown)

2. Position switch

3. Sensing plate

4. Clearance

Figure 60

3

1

2

4