Groundsmaster 4000--D/4010--D Page 5 -- 23 Electrical System

Warning Lights

Charge Indicator Light

Thechargeindicatorlightshould come on when the igni-

tion switch is in ON with the engine not running or with

an improperly operating charging circuit while the en-

gine is running.

To test the charge indicator light and circuit wiring,

ground the white wire attached to alternator. Turn igni-

tionswitch to ON; thechargeindicator light shouldillumi-

nate indicating correct operation of the electrical wiring

to the alternator.

Engine Oil Pressure Light

The engine oil pressure light should come on when the

ignition switch is in the ON position with the engine not

running. Also, it should light with the engine running if

the engine oil pressure drops below 7 PSI (0.5 kg/cm

2

).

To test theoilpressurelight and circuitw iring, ground the

green wire attached to oil pressure switch located on

right side of engine near the starter motor. Turn ignition

switchtoON;theoil pressure light should illuminate indi-

cating correct operation of the electrical wiring to the oil

pressure switch.

High Temperature Warning Light

If the engine coolant temperature rises to approximately

220

o

F (105

o

C), the high temperature light should come

on and the PTO (cutting decks) will disengage.

To test the high temperature warning lightandcircuitwir-

ing, start the engine and ground the gray wire attached

to the temperature sender attached to water flange on

engine (see Temperature Sender in this section). Warn-

ing light should illuminate.

Glow Plug Indicator Light

The glow plug light should come on when the ignition

switch is placed in ON/PREHEAT prior to placing the

ignition switch in START. The light should stay lit for

approximately seven (7) s econds while the ignition

switch is left in ON.

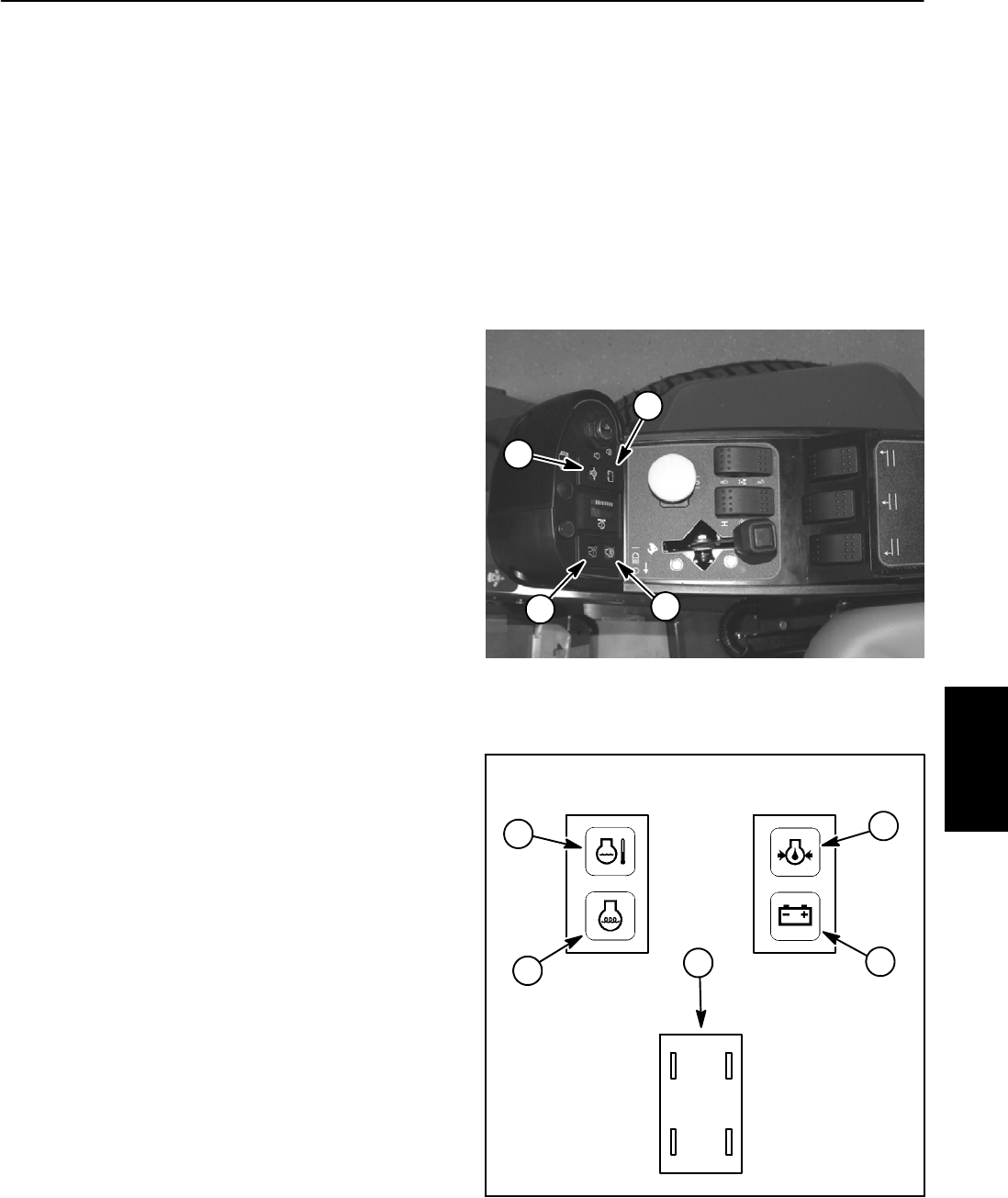

Testing Indicator Lights

1. Remove control arm covers to gain access to indica-

tor light and harness connectors (see Control Arm Dis-

assembly in the Service and Repairs section of Chapter

7 -- Chassis).

2. Locate the indicator light tobe tested anddisconnect

the wire harness electrical connector from the light.

3. Apply 12 VDC to terminals 1A and 2A (Fig. 22).

4. Ground terminals 1B and 2B (Fig. 22).

5. Both indicator lights should illuminate.

6. Connect wire harness electrical connector to the in-

dicator light.

7. Install control arm cover to machine (see Control

Arm Assembly in the Service and Repairs section of

Chapter 7 -- Chassis).

1. Charge indicator

2. Engine oil pressure

3. High temp warning

4. Glow plug indicator

Figure 21

1

2

3

4

Figure 22

1. Charge indicator

2. Engine oil pressure

3. High temp warning

4. Glow plug indicator

5. Warning light back

1A

2A2B

1B

4

3

2

1

5

Electrical

System