Groundsmaster 4000--D/4010--DPage 5 -- 6Electrical System

Troubleshooting

CAUTION

Remove all jewelry, especially rings and

watches, before doing any electrical trouble-

shooting or testing. Also, disconnect the battery

cables unless the test requires battery voltage.

For effective troubleshooting and repairs, you must

have a good understanding of the electrical circuits and

components used on this machine (see Chapter 10 --

Foldout Drawings).

If the machine has any interlock switches by--passed,

reconnect the switches for safety and efficient trouble-

shooting.

NOTE: Use the Diagnostic Display (see Special Tools

in this chapter) to test Toro Electronic Controller inputs

and outputs when troubleshooting an electrical problem

on your Groundsmaster.

Diagnostic Display

Groundsmaster 4000--D and 4010--D machines are

equipped with two (2) Toro Electronic Controllers (TEC)

which control machine electrical functions. The control-

lers monitor various input switches (e.g. ignition switch,

seat switch, neutral switch) and energize outputs to ac-

tuate solenoids or relays for the requested machine

function.

For the TEC to control the machine as desired, each of

the inputs (switches and sensors) and outputs (sole-

noids and relays) must be connected and functioning

properly.

The Diagnostic Display (see Special Tools in this chap-

ter) is a tooltohelpthetechnicianverify correctelectrical

functions of the machine.

IMPORTANT: The Diagnostic Display must not be

left connected to the machine. It is not designed to

withstand the environment of the machine’s every

day use. When use oft he DiagnosticDisplay iscom-

pleted, disconnect it from the machine and recon-

nect loopback connector to harnessconnector. The

machine will not operate without the loopback con-

nector installed on the harness. Store the Diagnos-

tic Display in a dry, secure, indoor location and not

on machine.

CAUTION

The interlock switches are for the protection of

the operator and bystanders and to ensure cor-

rect operation of the machine. Do not bypass or

disconnect switches. Check the operation of the

interlockswitchesdaily for proper operation. Re-

place any malfunctioning switches before oper-

ating the machine.

Verify Diagnostic Display Input Functions

1. Park machine on a level surface, lower the cutting

decks, stop the engine and apply the parking brake.

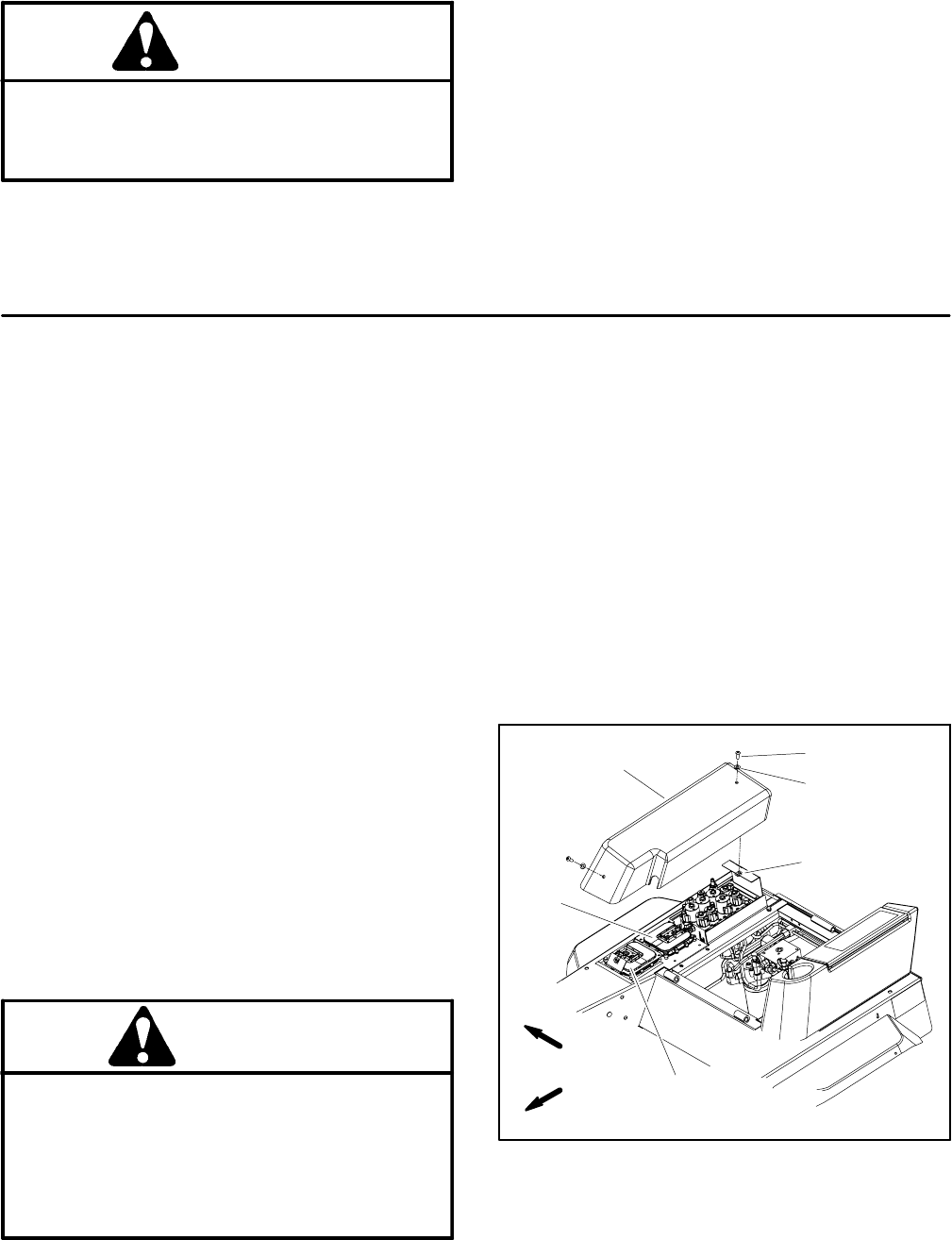

2. Remove the controller cover to allow access to wire

harness loopback connector (Fig. 8). Locate wire har-

ness communication port and loopback connector.

Carefully unplug loopback connector from harnesscon-

nector.

3. Connect the Diagnostic Display connector to the

wire harness connector. Make sure correct overlay de-

cal is positioned on the Diagnostic Display (Figs. 9 and

10).

1. Controller cover

2. Screw (2 used)

3. Flat washer (2 used)

4. U--nut (2 used)

5. TEC--5001

6. TEC--5002

Figure 8

FRONT

RIGHT

2

3

1

4

6

5