be pitted or blackened on one edge. Too many of these indicate a worn

commutator, and the motor should be replaced. The commutator may

be cleaned with narrow commutator stone if carbon build-up is present.

(File down the stone if it won’t fit in the brush holder hole.) Brush dust

can be loosened from the brush holder area by lightly filing the surfaces.

Dirt and brush dust inside the drive motor can cause a short and should

be vacuumed out of the motor.

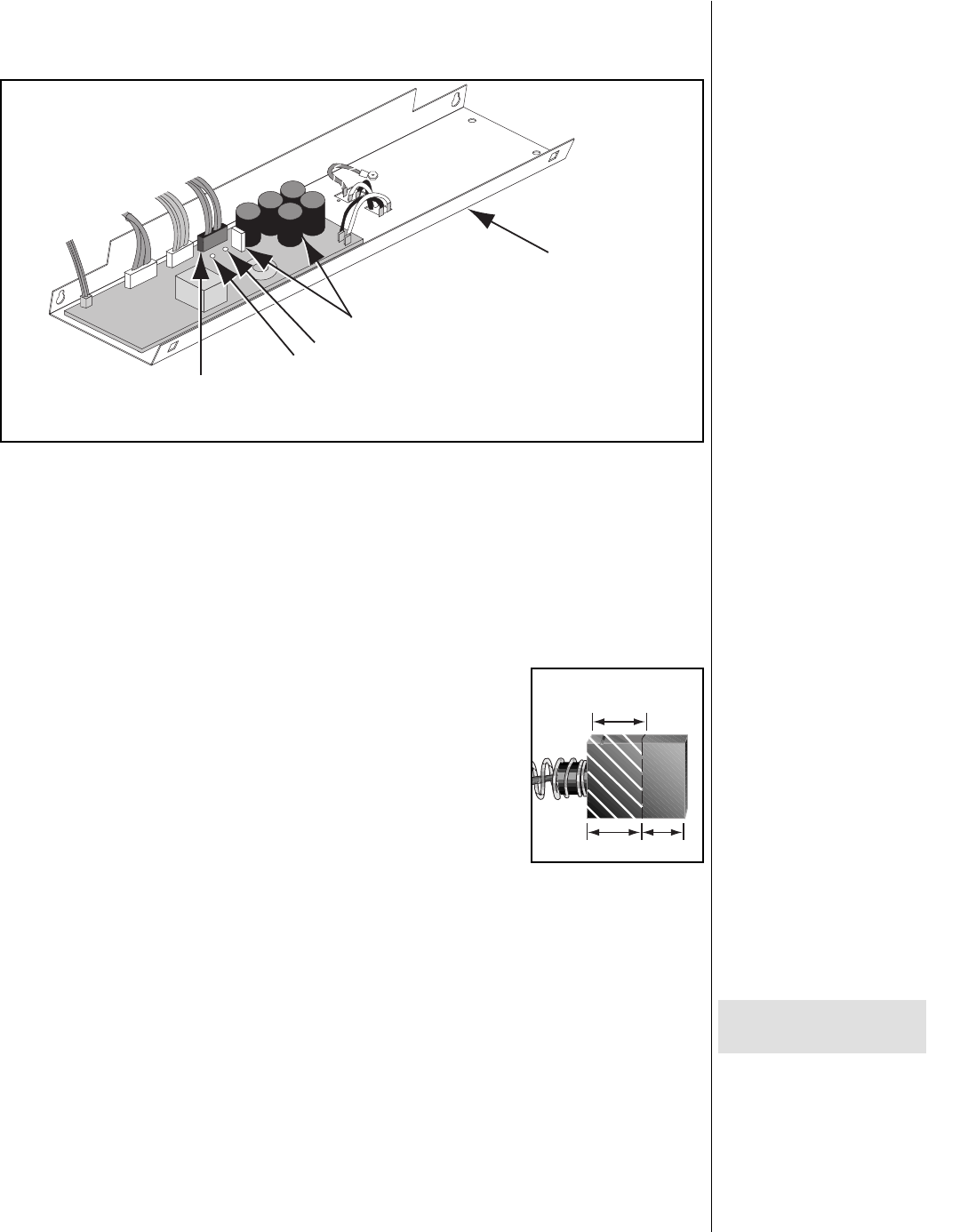

B. Inspect the brushes for signs of excessive wear or

cracks. The motor brushes must be replaced if one

or both is worn to .438” (7/16"/11.13mm) or less in

length, is broken or chipped, has a broken spring,

or binds in the motor. See Figure 2.

8. Secure the brushes.

A. Slide the brushes (new or original) into the motor

brush holders. If the new brush does not slide in

easily, the edges or corners of the brush can be lightly filed down. If

cleaning the motor, (see step 6A), and filing the brush doesn't allow the

brush to slide easily in the brush holder, the motor should be replaced.

NOTE: The motor may make a clicking noise as new brushes wear in. If you

reinstall the original brushes it is good to install them facing their original

position. Reversing the orientation of the brush can cause a clicking noise

during operation until the brushes wear in.

9. Secure the brush caps.

A. Place each brush in its brush holder and carefully push the spring in

while screwing on the brush cap. If the brush cap is damaged, order

Cybex replacement part number HX-10300-2.

Cybex 710T Treadmill Owner’s Manual

Page 7-3

Control During Operation . . 3-4

Data Readouts. . . . . . . . . . . 3-5

Selecting Programs

& Options . . . . . . . . . . . . . 3-6

Displaying Heart Rate . . . . . 3-6

Use of Programs . . . . . . . . . 3-7

Manual Mode . . . . . . . . . . . 3-8

P1 - Fitness Test Program. . 3-8

P2 - Weight Loss Program 3-10

P3 - Cardiovascular Program 3-12

P4 - Speed Challenge

Program . . . . . . . . . . . . . 3-14

P5 - Express Program. . . . 3-16

P6 - Hill Interval Program . 3-17

P7 - Speed Interval

Program . . . . . . . . . . . . . 3-18

P8 - Pike’s Peak Program . 3-19

P9 - River Run Program . . 3-20

P10 - 5 Kilometer Program 3-21

P11 - Demonstration

Program . . . . . . . . . . . . . 3-22

P101-P110 - Saved

Program . . . . . . . . . . . . . 3-22

Workout Tips. . . . . . . . . . . 3-24

4

Preventive Maintenance

Regular Maintenance

Activities. . . . . . . . . . . . . . 4-1

Cleaning Your Treadmill. . . . 4-1

Running Belt Maintenance . 4-2

Other Preventive

Maintenance . . . . . . . . . . . 4-6

Service Schedule . . . . . . . . . 4-7

Log Sheet. . . . . . . . . . . . . . . 4-8

5 Setup & Assembly

Quick Setup . . . . . . . . . . . . 5-1

Choosing & Preparing a Site 5-1

Electrical Power

Requirements. . . . . . . . . . 5-3

Unpacking. . . . . . . . . . . . . . 5-3

Assembling the Treadmill. . . 5-4

Testing the 710T Operation. 5-9

Setting Operation Options. 5-10

6 Customer Service

Contacting Service . . . . . . . 6-1

Serial Number & Voltage . . . 6-1

Warranty . . . . . . . . . . . . . . . 6-1

Return Material Authorization . .

(RMA) . . . . . . . . . . . . . . . . 6-4

Damaged Parts . . . . . . . . . . 6-4

Ordering Parts. . . . . . . . . . . 6-5

7 Service

Service Instruction . . . . . . . . 7-1

Motor Brushes. . . . . . . . . . . 7-1

Motor Current & Voltage . . . 7-4

Running Belt & Deck . . . . . . 7-7

Drive Belt. . . . . . . . . . . . . . . 7-9

Front Roller . . . . . . . . . . . . . 7-9

Rear Roller . . . . . . . . . . . . 7-10|

Error Codes. . . . . . . . . . . . 7-11

Diagnostic Tests . . . . . . . . 7-13

Parts List . . . . . . . . . . . . . . 7-20

Exploded View . . . . . . . . . . 7-23

710T Schematic . . . . . . . . . 7-24

Figure 2

.438" (7/16")

(11.13 mm)

Replace OK

Motor

Cable

Front

Panel

!WARNING: Avoid Touching

R34 and Black Capacitors

+

-

Figure 1