MHD56087 - Edition 4 21

REVIEW COPY 6

-

21

-

02

TROUBLESHOOTING (CONTINUED)

LUBRICATION

To ensure continued satisfactory operation of the winch, all points

requiring lubrication must be serviced with correct lubricant at the

proper time interval as indicated for each assembly.

Lubrication intervals recommended in this manual are based on

intermittent operation of winch, eight hours each day, five days per

week. If winch is operated almost continuously or more than eight

hours each day, more frequent lubrication will be required. Also,

lubricant types and change intervals are based on operation in an

environment relatively free of dust, moisture, and corrosive fumes.

Use only those lubricants recommended. Other lubricants may

affect performance of winch. Approval for the use of other

lubricants must be obtained from your Ingersoll-Rand distributor.

Failure to observe this precaution may result in damage to the

winch and its associated components.

Note: Intervals are based on winch operation in a normal

environment as described in “INSPECTION” section. In ‘Heavy’

or ‘Severe’ operating conditions adjust lubrication intervals

accordingly.

General Lubrication

1. Drain and replace oil in the motor, disc brake and reduction

gear after the first 50 hours of initial winch operation.

Thereafter, drain and replace oil according to intervals

recommended.

2. Always inspect removed oil for evidence of internal damage

or contamination (metal shavings, dirt, water, etc.). If

indications of damage are noted, investigate and correct

before returning winch to service.

3. After winch operation, allow oil to settle before topping off.

4. Always collect lubricants in suitable containers and dispose

of in an environmentally safe manner.

Reduction Gear and Disc Brake Lubrication

Refer to Dwg. MHP0501 on page 22.

The reduction gear and disc brake are filled and shipped with oil

from the factory. Check oil level before initial winch operation.

These components are splash lubricated by the oil in the housing

and have no other means of lubrication. It is therefore important to

use high quality Extreme Pressure (EP) rust and oxidation

inhibited gear oils to ensure maximum performance and minimum

down time for repairs. Oil capacity is approximately 3 quarts (2.8

litres). Oil from the reduction gear assembly also provides

lubrication for the disc brake.

On winches equipped with a disc brake, the reduction gear is

vented through the disc brake breather plug.

Recommended Lubricant

* Units are shipped from factory with ISO VG 100 (SAE 3 EP)

lubricant. Reduction Gear capacity is approximately 3 quarts

(2.8 litres).

Recommended Grease

Automatic Band Brake:

Brake cylinder will not

release.

Band brake out of adjustment. Adjust band brake to maintain correct cylinder stroke.

Leaking cylinder seals. If air is noticed escaping from cinder breather when attempting to release

brake, replace or repair cylinder.

Dirty filter in air supply. Clean or replace filter.

Faulty dump valve. Check dump valve exhaust port. Air should exhaust when control valve

handle is neutral. If no air escapes, replace dump valve.

Automatic Disc Brake:

Brake fails to release. Low air supply pressure. Ensure air pressure at inlet to disc brake is at least 50 psig (3.4 bar/340 kPa).

Leaking piston seals. Inspect brake breather. If air escapes from brake breather when attempting to

release brake, replace brake seals.

No release pressure at brake port. Check for proper operation of winch controls.

Sticking brake piston. Apply 50 psig (3.4 bar/340 kPa) to brake release port and check for brake

disc movement. (Brake discs can be viewed through brake breather hole.)

If brake discs do not move, disassemble and inspect disc brake as described

in “MAINTENANCE” section.

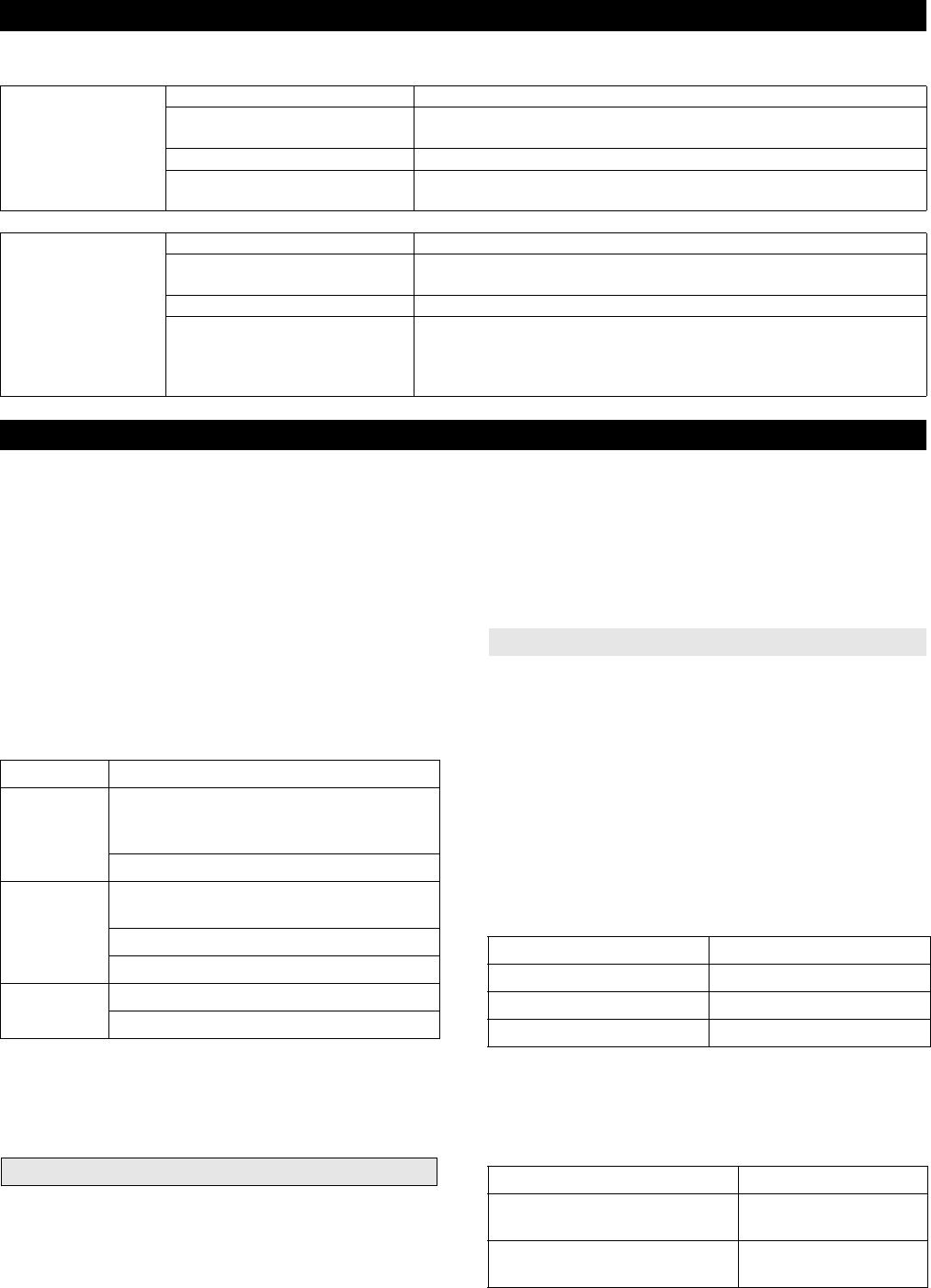

INTERVAL LUBRICATION CHECKS

Start of each

shift

Check flow and level of air line lubricator

(approximately 6 to 9 drops per minute required

at maximum motor speed).

Check winch motor oil level.

Monthly Lubricate components supplied by grease

fittings.

Inspect and clean or replace air line filter.

Check reduction gear oil level.

Yearly Drain and refill winch reduction gear oil.

Drain and refill winch motor oil.

Temperature Type Oil

Below 32° F (0° C) ISO VG 68 (SAE 2 EP)

32° to 80° F (0° to 27° C) ISO VG 100 (SAE 3 EP)*

Above 80° F (27° C) ISO VG 150 (SAE 4 EP)

Temperature Type Grease

-20° to 50° F

(-30° to 10° C)

EP 1 multipurpose

lithium based grease

30° to 120° F

(-1° to 49° C)

EP 2 multipurpose

lithium based grease