MHD56087 - Edition 4 15

REVIEW COPY 6

-

21

-

02

Winch Brakes

Automatic Disc Brake

The automatic disc brake is spring applied, air released. When the

winch is operated in payout direction, air pressure acting on the

diaphragm overcomes spring pressure and releases brake. The

brake automatically engages when winch operation is returned

from payout direction to neutral or when shifted to haul-in

direction. When winch is in neutral or haul-in positions the brake

air is vented and brake springs apply the brake. The springs, acting

on the pressure plate, compress brake friction and separator plates

and engage brake to prevent drum rotation in payout direction.

The cam type sprag clutch assembly allows drum rotation in haul-

in direction with brake plates engaged, but prevents drum from

rotating in payout direction.

A minimum air pressure of 25 psi (1.72 bar/172.4 kPa) is required

to release brake.

Disc brake adjustment is not required. If disc brake does not

operate properly it must be disassembled, inspected and repaired.

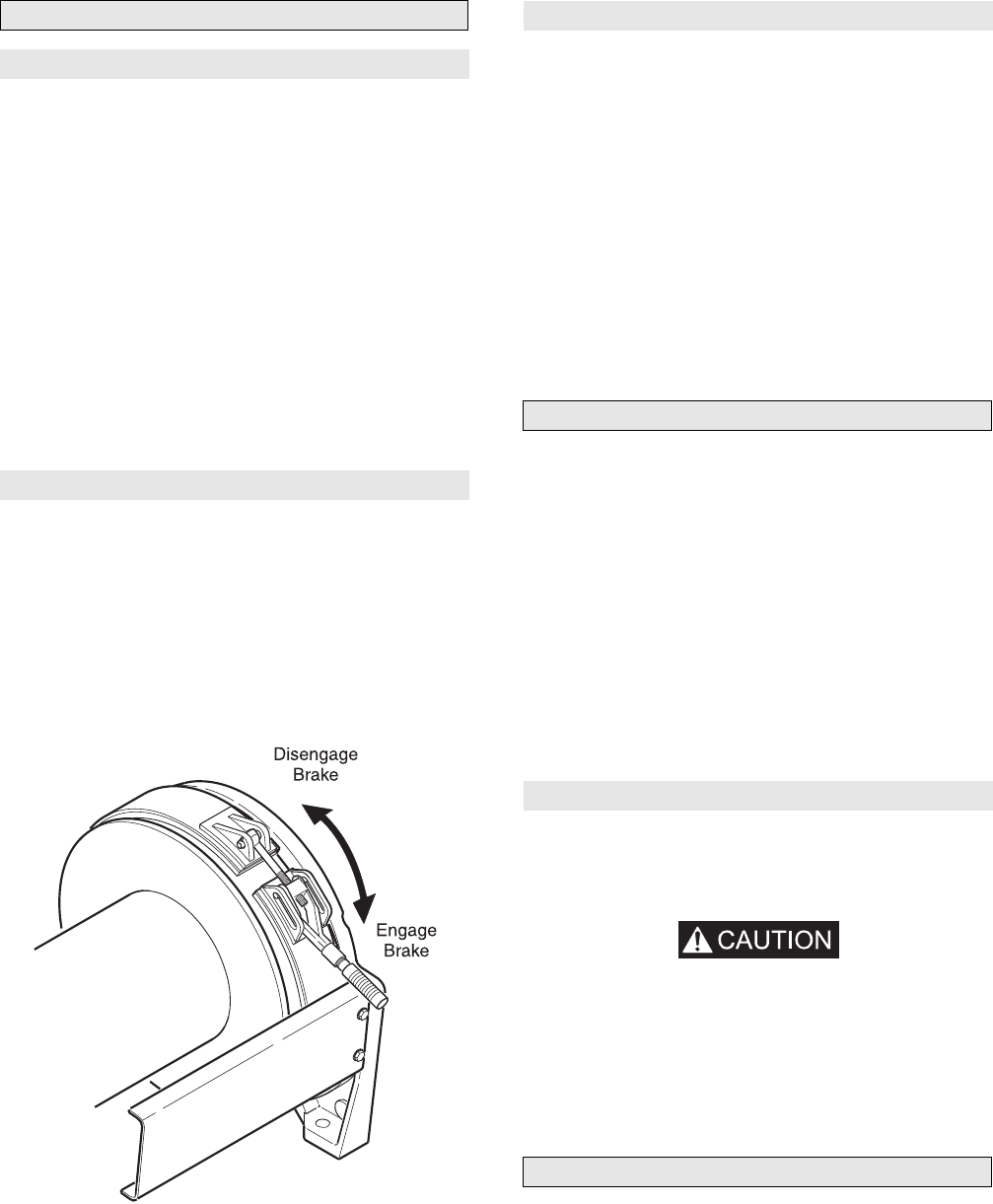

Manual Drum Brake (optional feature)

Refer to Dwg. MHP1375 on page 15.

The manual drum brake may be applied by pushing down on the

handle and released by pulling up. By pushing the handle down

fully, it will go over-center and lock in that position, preventing

drum rotation. The drum brake must be kept properly adjusted to

hold the required load. Refer to ‘Adjustments’ in the

“MAINTENANCE” section. If brake band cannot be adjusted to

hold the rated load, the brake must be disassembled, inspected and

repaired.

Drum Brake Handle Operation

(Dwg. MHP1375)

Automatic Drum Brake (optional feature)

The automatic drum brake is a spring applied, air released,

externally mounted brake which uses an air actuated, spring

loaded cylinder to automatically disengage the brake when the

motor is operated in either the haul-in or payout directions. Air

pressure directed to the cylinder overcomes spring pressure to

release brake and allow drum to rotate.

When the control valve is placed in the neutral position, air in the

cylinder is vented which allows the cylinder spring to

automatically engage brake and prevent drum rotation.

Adjustments to the cylinder clevis can be made to compensate for

normal brake lining wear. The drum brake must be kept properly

adjusted to hold the required load. Refer to ‘Adjustments’ in the

“MAINTENANCE” section. If brake band cannot be adjusted to

hold rated load, the brake must be disassembled, inspected and

repaired.

Constant Tension Manifold (optional feature)

Refer to Dwg. MHP2436 on page 52.

With auxiliary valve (744) in the ‘NORMAL’ position, the winch

control valve will provide normal winch operation. With auxiliary

valve selector in the ‘TENSIONING’ position, the winch will

automatically haul-in wire rope to maintain tension.

The auxiliary valve provides a preset air pressure to the air motor

and disc brake. This allows the brake to be released, and winch to

over haul during ‘TENSIONING’ operations. In this position the

winch will maintain a constant tension on the wire rope.

The auxiliary valve comes set at zero from the factory. All

adjustments must be made in the field. These adjustments can be

changed at any time to accommodate the current load. Refer to

‘Adjustments’ in the “MAINTENANCE” section for procedures.

Operation

Place auxiliary valve in ‘NORMAL’ position and use winch

control to position the end of load line at the load. Connect load

line to the load and use winch control to remove all slack from the

load line.

• Ensure slack load line is taken up by operating winch control

valve with selector in NORMAL position. If selector lever is

placed in TENSION position the winch will immediately

attempt to establish line tension causing line to ‘snap’

resulting in injury or damage to property.

Actuate auxiliary valve to ‘TENSIONING’ position. Winch will

automatically haul-in to maintain tension on load line.

Free Spool (optional feature)

Refer to Dwg. MHP2414 on page 61.

The Free Spool option allows wire rope to be spooled from the

drum without operating winch motor.

During normal winch operations the free spool is in non-free spool

position. The output shaft connects outboard upright to drum. The

free spool handle is in the ‘DOWN’ position.