32

BAS-761

1

2

BAS761

1.7

1

2

BAS761

1.7

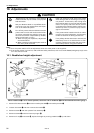

10-2. Needle and rotary hook timing

r

e

¡ After needle-bar q is raised from its lowest position, rotary hook point w must be aligned with the center of needle

e when the lower end of needle-bar q is matched the end of gauge 2.

¡ If rotary hook point w is not aligned with the center of needle e, loosen screws r and align the center of needle e

with rotary hook point w.

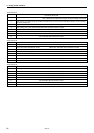

¡ Timing gauge

If there is a recess at the right edge of the bed, use gauge A; if there is none, use gauge B.

10. Adjustments

q

w

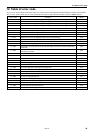

10-3. Presser foot height adjustment

The standard presser foot height is 16.5 mm (for x2.4 rotary hook) or 14.5mm (for x1.7 rotary hook) above the needle

plate when the presser foot q is raised.

1. Loosen nut w and then pressure adjusting screw e.

2. Press the FOOT button to raise working presser foot q.

3. Remove face-plate oil cap r and loosen screw t. Adjust the height by moving presser bar y.

The standard spring tension for the sewing clamp spring is obtained when the height of the presser foot adjustment

screw is 37 mm.

Check that the point of the needle does not protrude below the presser foot when the needle is at its highest position.

Gauge

• for x1.7 rotary hook 1.8mm

• for x2.4 rotary hook 2.4mm

0 – 0.05mm

e

w

t

r

y

q

for x2.4 rotary hook 16.5mm

for x1.7 rotary hook 14.5mm

37mm

x2.4 rotary hook

(S51288-000)

x1.7 rotary hook

(S52232-000)

x2.4 rotary hook

(S54742-000)

Recess

A With recess

• for x1.7 rotary hook 1.8mm

• for x2.4 rotary hook 1.2mm

B Without recess

■ x1.7 rotary hook

1

BAS761

1.7

2

1

BAS761

1.7

2

1

S54742000

BAS761

2.4

2

1

S54742000

BAS761

2.4

2

MP1.2

1

2

MP1.2

1

2