Groundsmaster 4000--D Hydraulic SystemPage 4 -- 35

Procedure for Traction Circuit Relief Pressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

Move machine to an open area, away from

people and obstructions.

CAUTION

2. Drive machine to an open area, lower cutting decks,

turn the engine off and apply the parking brake.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3. Connect a 10,000 PSI (700 bar) pressure gauge to

traction circuit test port for function to be checked (Fig.

22 or 23).

4. Starttheengine and move throttle to full speed(2870

RPM). Release parking brake. Make sure that trans-

port/4WD switch is in the transport position.

5. Siton seat, apply brakes fully and slowlydepress the

traction pedal in the appropriate direction. While

pushing traction pedal, look at pressure reading on

gauge:

GAUGE READING TO BE:

Forward: 3750 to 4250 PSI (259 bar to 293 bar)

Reverse: 4750 to 5250 PSI (328 to 362 bar)

6. Release traction pedal and stop engine. Record test

results.

7. If traction pressure is too low, inspect traction pump

relief valves (Fig. 24). Clean or replace valves as neces-

sary. These cartridge type valves are factory set, and

are not adjustable. If relief valves are in good condition,

traction pump or wheel motors should be suspected of

wear and inefficiency.

NOTE: Seal leakage across pilot directional valves

PD1 and PD2 in 4WD manifold can also cause low for-

ward traction pressure with reverse pressure meeting

specifications.

8. When testing is completed, disconnect pressure

gauge from test port.

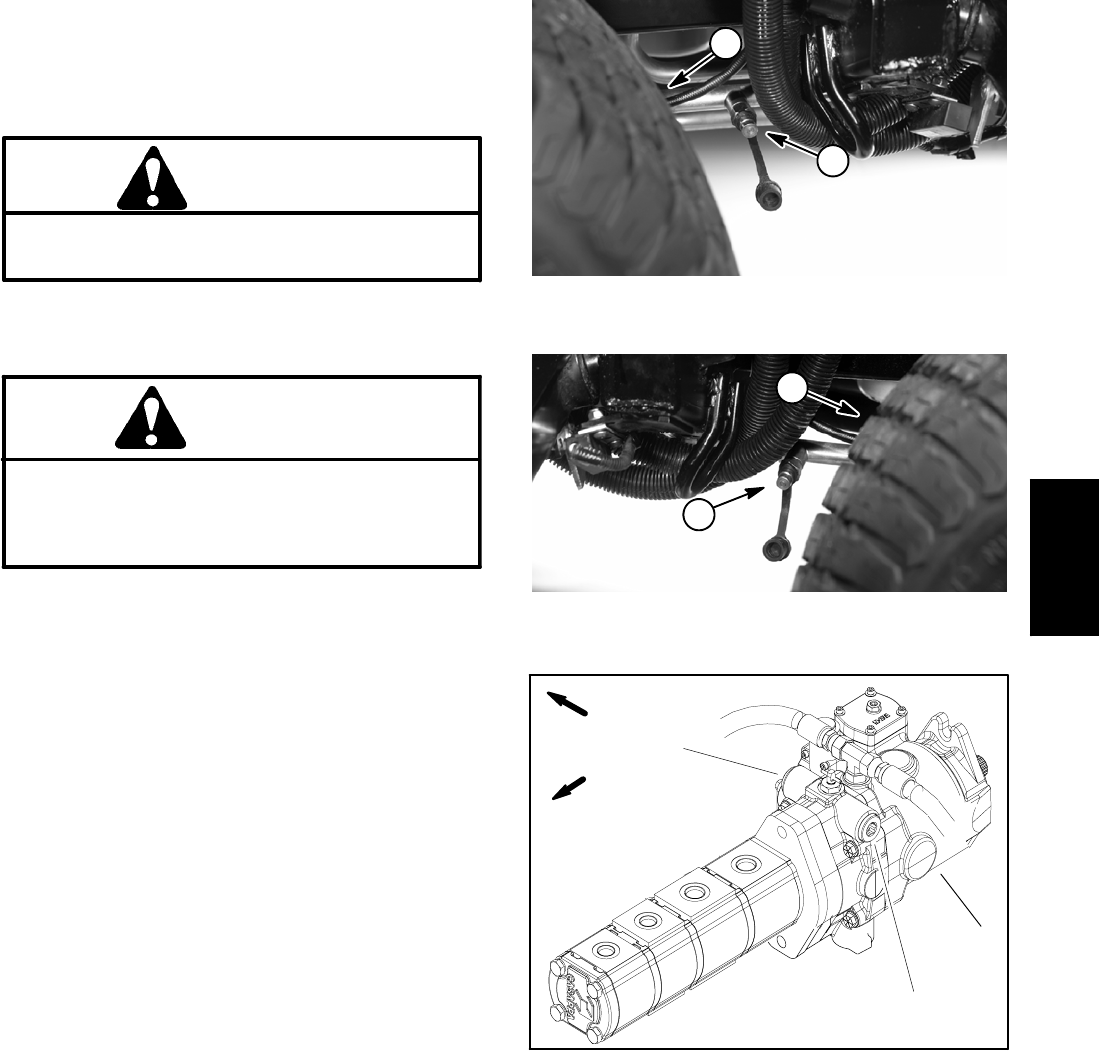

1. Forward traction port 2. Left front wheel

Figure 22

1

2

1. Reverse traction port 2. Right front wheel

Figure 23

1

2

1. Forward relief valve

2. Reverse relief valve

3. Traction pump

Figure 24

1

2

3

FRONT

RIGHT

Hydraulic

System