Groundsmaster 4000--DCutting Decks

Page 8 -- 4

Troubleshooting

There are a number of factors that can contribute to un-

satisfactory quality of cut, some of which may be turf

conditions. Turf conditions such as excessive thatch,

uneven ground conditions, “sponginess” or attempting

to cut off too much grass heightmay not always beover-

come by adjusting the machine.

Remember that the “ effective” or actual height--of--cut

depends on cutting deck weight, tire pressures, hydrau-

lic counterbalance settings and turf conditions. Effective

height--of--cut willbedifferentthan thebench setheight--

of--cut.

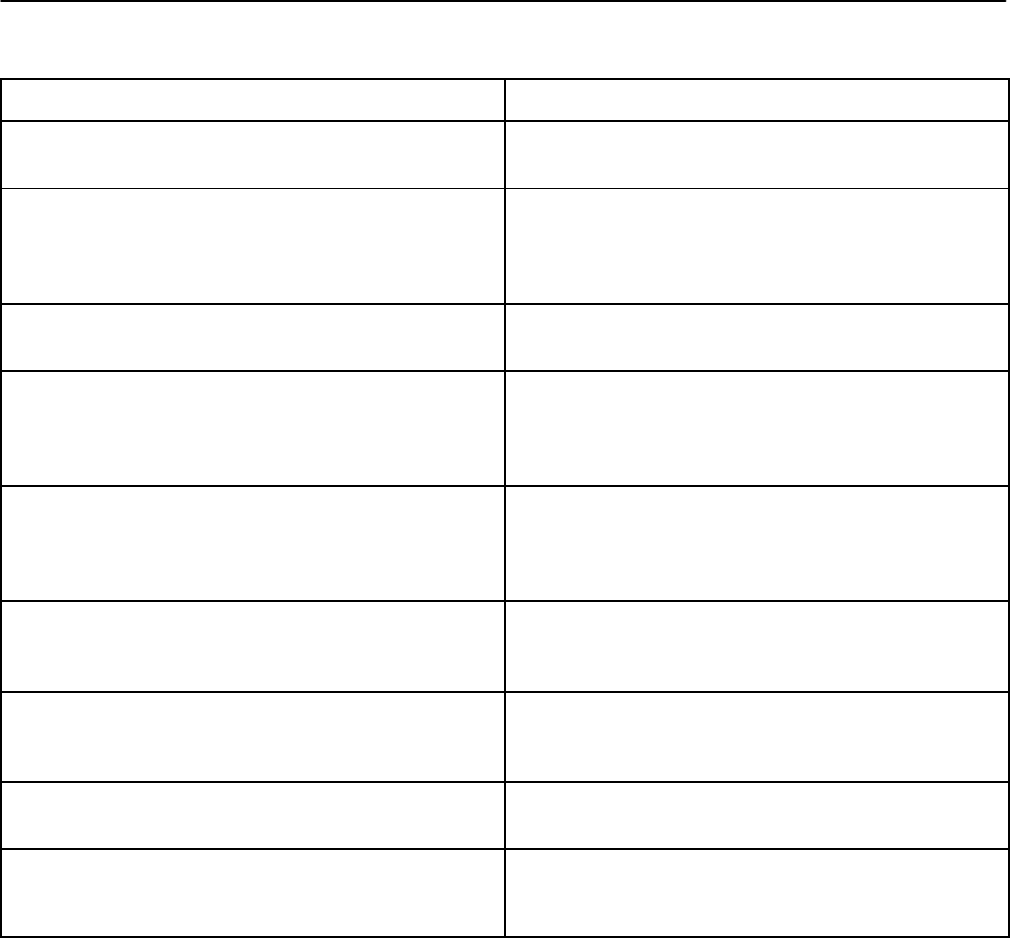

Factors That Can Affect Quality of Cut

Factor Possible Problem/Correction

1. Maximum governed engine speed. Check maximum governed engine speed. Adjust

speed to specifications if necessary.

2. Blade speed. All deck blades should rotate at the same speed.

See items in Troubleshooting Section of Chapter 4 --

Hydraulic System.

3. Tire pressure. Check air pressure of each tire including castor tires.

Adjust to pressures specified in Operator’s Manual.

4. Blade condition. Sharpen blades if their c utting edges are dull or nicked.

Inspect blade sail for wear or damage. Replace blade if

needed.

5. Mower housing condition. Make sure that cutting chambers are in good condition.

Keep underside of deck clean. Debris buildup will

reduce cutting performance.

6. Height--of--cut. Make sure all c utting decks are set at the same

height--of--cut. Set decks as specified in the Operator’s

Manual.

7. Cutting deck alignment and ground following. Check lift arms and cutting deck pivot linkages for

wear, damage or binding. Also, inspect for bent or

damaged pivot shafts.

8. Roller and castor wheel condition. All rollers and caster wheels should rotate freely.

Replace bearings if worn or damaged.

9. Grass c onditions. Mow when grass is dry for best cutting results. Also,

remove only 1” (25 mm) or 1/3 of the grass blade when

cutting.