Groundsmaster 4000--D Page 7 -- 9 Chassis

Rear Arm Removal (Fig. 8)

1. Park machine on a level surface, lower cutting

decks, stop engine, apply parking brake and remove

key from the ignition switch.

2. Removehair pinandclevis pin thatconnects damper

link to cutting deck (Fig. 9).

3. Removecap screw and locknutthat secures rod end

of rear arm to cutting deck. Locate and remove spacer

from each side of rod end.

4. Remove lock nut and lock washer that secures rear

arm pivot shaft. Slide pivot shaft from hub and rear arm.

Remove rear arm assembly from machine.

Rear Arm Disassembly (Fig. 8)

1. Disassemble rear arm assembly using Figure 8 as a

guide.

Rear Arm Assembly (Fig. 8)

1. Slide large flat washer, spring, plastic bearing,

another large flat washer and small flat washer onto

spring shaft. Loosely secure components to shaft with

one jam nut.

2. Slide the straight bushing and plate onto other end

of spring shaft.

3. While holding flats on end of spring shaft, rotate jam

nut (on other end of assembly) until components are

snug but spring is not compressed.

4. Insert assembly into rear arm housing.

5. From open end of rear arm housing, insert a 3/4”

socket onto spring shaft jam nut. Tighten jam nut fully.

6. Mount plate to rear arm housing with two (2) cap

screws and lock nuts. Grasp end of spring shaft. Push

inward and pull outward on shaft to determine endplay

in assembly.

IMPORTANT: All endplay must be removed from as-

sembly to allow proper operation and ensure long life.

7. Loosen jam nut, 1/2 turn at a time, until all endplay

in shaft is removed.

8. Remove two (2) cap screws and nuts securing plate

to rear arm housing. Remove spring shaft assembly

from housing.

9. Thread remaining jam nut onto end of spring shaft

and, while retaining inner jam nut to preventit from mov-

ing, torque outer jam nut from 22 to 28 ft--lb (30 to 37

N--m) to lock adjustment.

10.Thoroughly pack spring with grease. Install spring

shaft assembly into housing and secure plate with four

(4) cap screws and lock nuts.

11.Threadrod end (item 8)with jam nut (item 9) into end

of spring shaft. Do not tighten jam nut at this time.

12.If rod ends (item 31) were removed from damper

(item 30), apply thread locking compound to damper

shaft threads before installing rod ends. Securedamper

to bellcrank and rear arm with cap screws and lock nuts.

Torque fasteners from 270 to 330 in--lb (31 to 37 N--m).

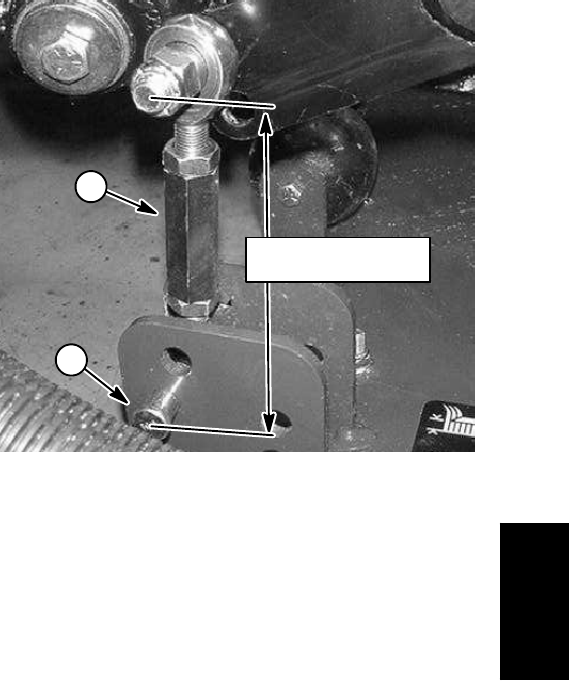

13.If damper link was disassembled, adjust the length

of the link from 5.295” to 5.445” (134.5 to 138.3 mm)

(Fig. 9).

14.If damper springs (item 37) were removed, tighten

lock nuts so that bushings (item 36) are free to rotate.

1. Damper link assembly 2. Clevis pin

Figure 9

1

2

5.295” to 5.445”

(134.5 to 138.3 mm)

Chassis