Groundsmaster 4000--D Hydraulic SystemPage 4 -- 33

ProcedureforTraction CircuitChargePressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2. Park machine on a level surface with the cutting

decks lowered and off. Make sure engine is off and the

parking brake is applied.

3. Raise and support operator seat.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

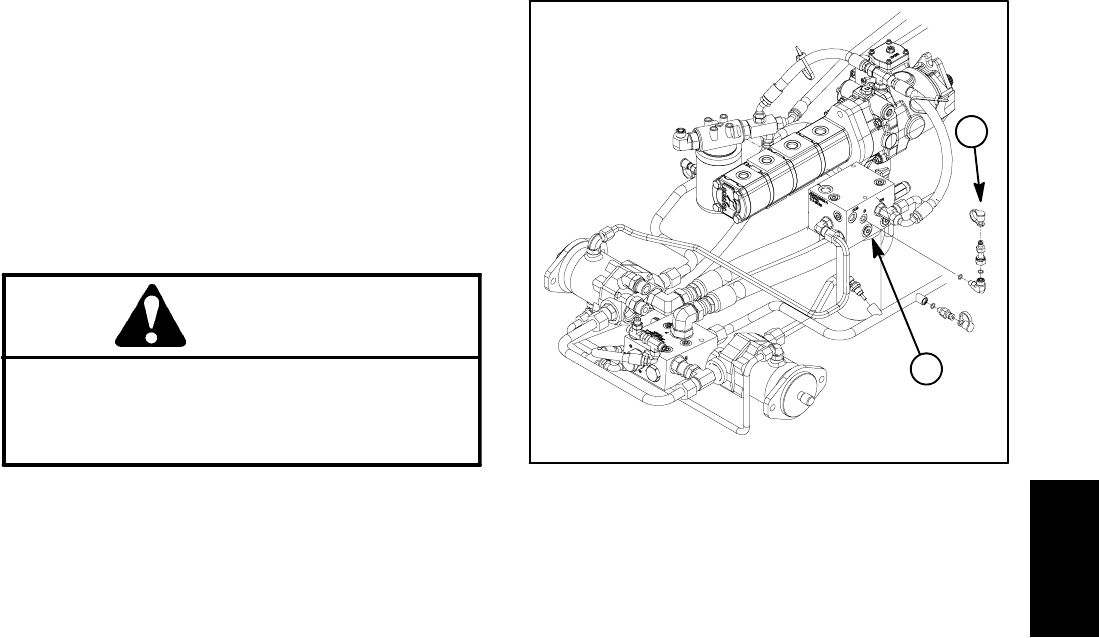

4. Connect a 1000 PSI (70 bar) pressure gauge onto

charge pressure test port on filter manifold (Fig. 21).

5. Start the engine and put throttle at full engine speed

(2870 RPM) with no load on the hydraulic system.

GAUGEREADINGTOBE200 to 300 PSI (13.8 to

20.6 bar).

6. Stop engine and record test results.

7. If there is no pressure or pressure is low, check for

restrictioninpump intakeline.Also, inspectchargerelief

valve located in filter manifold (see Hydraulic Manifold

Service: Filter Manifold in the Service and Repairs sec-

tionofthis chapter).If necessary,check forinternal dam-

age or worn parts in gear pump.

8. Also, with the pressure gauge still connected to the

charge pressure test port, take a gauge reading while

operating the machine in forward and reverse. Start the

engine and put throttle at full engine speed (2870 RPM).

Apply the brakes and push the traction pedal forward,

then reverse.

GAUGEREADINGTOBE200 to 300 PSI (13.8 to

20.6 bar).

9. If pressure is good under no load, but consistently

drops below specification when under traction load, the

piston pump and/or traction motor(s) should be sus-

pected of wear and inefficiency. When the pump and/or

traction motor(s) are worn or damaged, the charge

pump is not able to keep up with internal leakage in trac-

tion circuit components.

10.When testing is completed, disconnect pressure

gauge from test port.

1. Charge pressure port 2. Filter manifold

Figure 21

1

2

Hydraulic

System