Groundsmaster 4000--DPage 6 -- 18Axles, Planetaries and Brakes

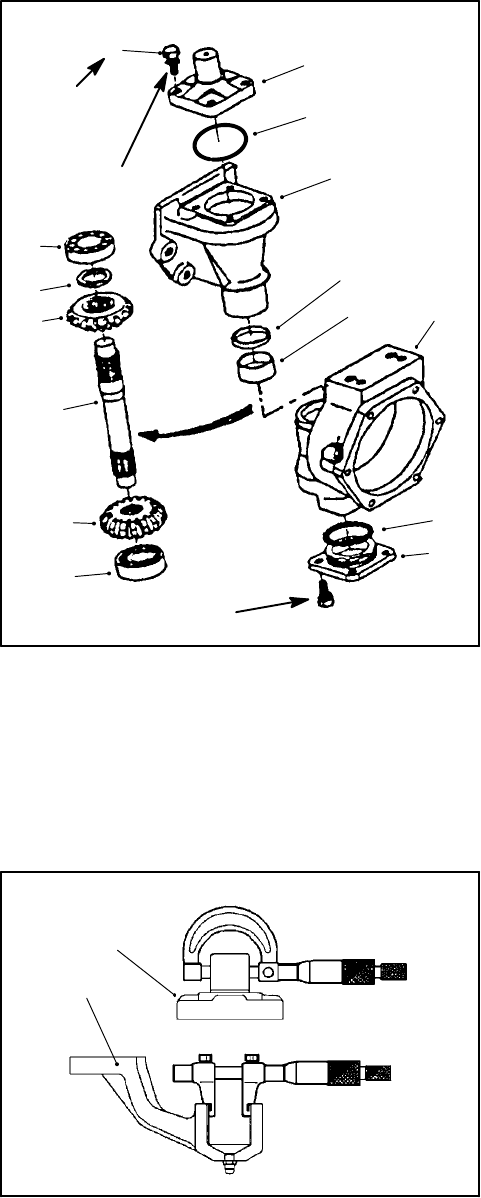

5. Remove the knuckle pin mounting bolts and the

knuckle pin.Remove the gasketandany remaining gas-

ket material from both mating surfaces (Fig. 18).

6. While holding the bevelgear case, tap the upper end

of the bevel gear shaft out of the upper bearing and up-

per bevel gear.

7. Pull the bevel gear case from the axle case and re-

move the upper bevel gear and collar from the gear

case.

8. Remove the axle case cover screws, cover and the

O-ring from the axle case.

9. Remove the plug (not shown) and sealing washer

from the center of the axle case cover. While holding the

axle case cover, lightly tap the lower end of the bevel

gear shaft out of thelower bearing and lower bevel gear.

10.Remove and discard bevel gear shaft seal from axle

case (Fig. 18).

1. Knuckle pin

2. Bolt (4 used)

3. O--ring

4. Bevel gear case

5. Upper bearing

6. Bevel gear shaft

7. Collar

8. Upper bevel gear

9. Lower bevel gear

10. Lower bearing

11. Axle case

12. Axle case cover

13. O-ring

14. Shaft seal

15. Bushing

Figure 18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17 to 20 ft--lb

(23to27N--m)

17 to 20 ft--lb

(23to27N--m)

Threadlocking

Compound

Bevel Gear Case and Axle Case Inspection

1. Measuretheknuckle pin O.D. and the axle case sup-

port bushing I.D. to determine the bushing to pin clear-

ance (Fig. 19). Replace components as necessary.

BUSHING TO PIN CLEARANCE:

0.002 to 0.016 in. (0.05 to 0.40 mm)

KNUCKLE PIN O.D. ( Factory Spec.):

0.982 to 0.983 in. (24.95 to 24.98 mm)

AXLE CASE SUPPORT BUSHING I.D.

(Factory Spec.):

0.984 to 0.987 in. (25.00 to 25.08 mm)

2. Inspectall gears, shafts, bearings, cases and covers

for damage and wear. Replace c omponents as neces-

sary.

1. Knuckle pin 2. Axle case support

Figure 19

1

2