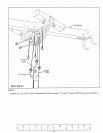

STEP 52

If upon completion of assembl3:, the I~AD PLATE (72) does not

sit on top of the first WEIGHT PLATE (105), push the HEAD

PLATE (72) down, insert the WEIGHT STACK PIN (75)

peffom~ several repetitions at the press station. Tiffs ~511 relax the

cable system and prevent the HEAD PLATE (72) from lifting up.

If after completing previous step, the HEAD PLATE (72) still does

not sit on top of the first WEIGHT PLATE (105) or if there

excess slack in the cable system, adjust the two threaded ends of

the HEAD PLATE CABLE (102) accordingly and retighten the jam

nuts.

If there is excess slack in the AB or PEC DEC cable ~’stem, adjust

the threaded end of the AB CABLE (103) accordingly and re-

tighten the jam nut.

FIGURE 52

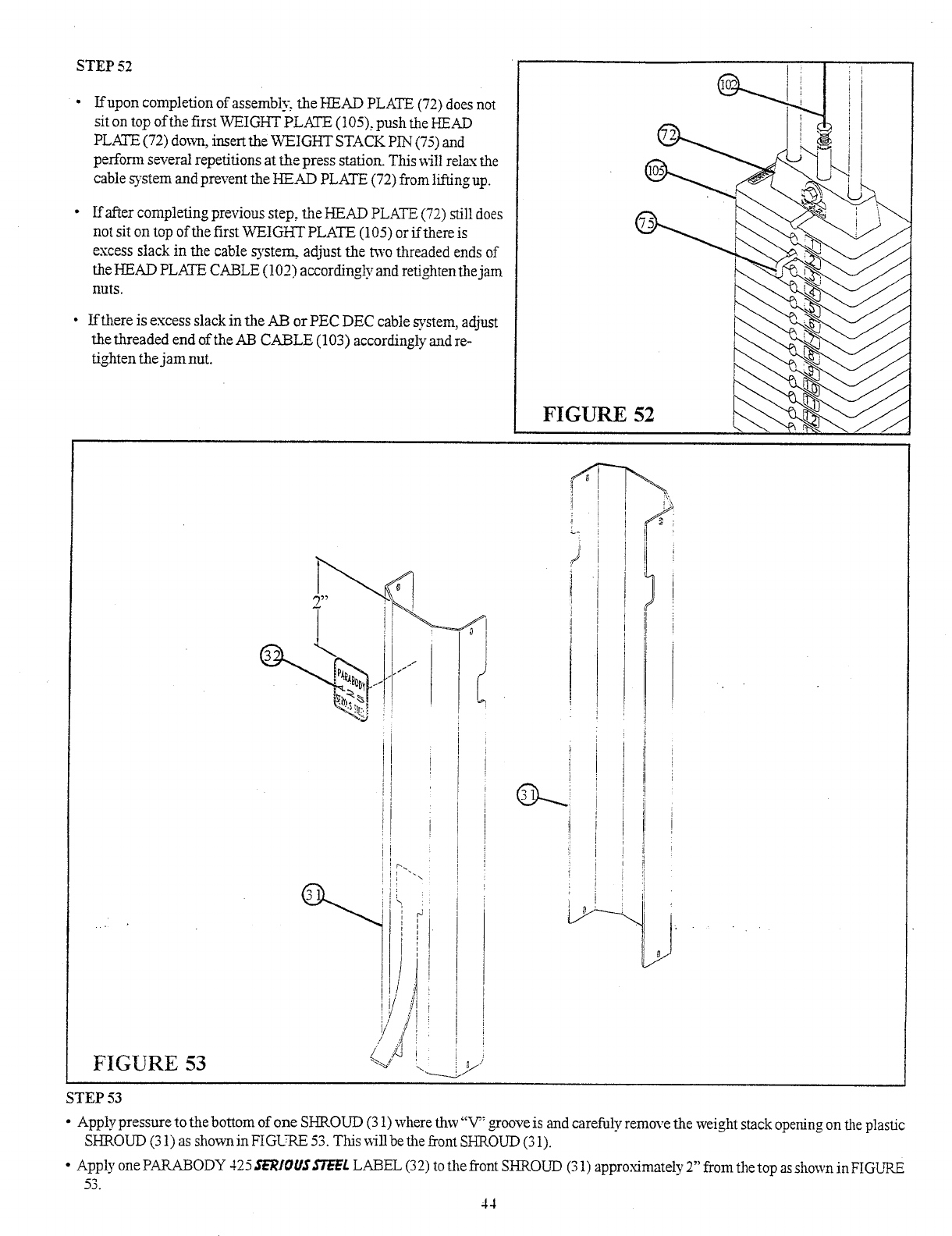

FIGURE 53

STEP 53

¯ Apply pressure to the bottom of one SHROUD (31) where thw "V" groove is and carefuly remove the weight stack opening on the plastic

SHROUD (31) as shown m FI GUP,.E 53. Tiffs ~411 be the front SHROUD (31).

¯ Apply one PARABODY 425,~’~I01155"F~.E£ LABEL (32) to the front SHROUD (31) approximately 2" from the top as shown in FIGURE

53.

44