Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 19

Mow

A four section gear pump is coupled to the piston (trac-

tion) pump. Hydraulic flow for the mow circuit is supplied

by two sections of the gear pump. The gear pump sec-

tion closest to the piston (traction) pump supplies hy-

draulic flow to the side cutting decks, while the next gear

pump section supplies the front cutting deck.

Each cutting deck is controlled by a hydraulic manifold

equipped with a solenoid control valve (S), bypass car-

tridge (LC1), brake cartridge (LC2) andtwo (2) relief car-

tridges (R V1 and RV2). Circuit pressure can be

measured at port (G) of the hydraulic manifold for each

cutting deck.

NOTE: To engage the mow circuit, the operator must

be in the operator seat, the cutting deck(s) must be fully

loweredandthetractionspeedmustbeintheLow

speed (4WD) position.

PTO Not Engaged

When the PTO switch is OFF or if the deck is raised with

the PTOswitch ON, the PTO manifold solenoid valve (S)

is not energized and the solenoid spool is in the neutral

position. This solenoid spool in neutral allows a small

amount of hydraulic flow toreturnto tank through a man-

ifold sensing line which causes a pressure increase that

shifts bypass cartridge LC1. The pump flow is routed

throughshifted LC1 and out manifold port P2. Brake car-

tridge LC2 remains in the unshifted position to prevent

any return flow from the deck motor to keep the motor

from rotating.

Return flow from the front and right PTO manifolds is

routedthroughthe oil cooler,oilfilterand then to the gear

pump input. Return flow from the left PTO manifold pro-

vides supply f or the right deck.

PTO Engaged

When the PTO switch is turned ON and the decks are

lowered, the PTO manifold solenoid valve (S) is ener-

gized by the TEC--5001 controller. This shifted solenoid

valve prevents any sense line flow through the valve

which allows the bypass cartridge LC1 to be in itsneutral

position. Gear pump flow entering the manifold is routed

out manifold port M1 and to the cutting deck motor. The

return flow from the deck motor re--enters manifold port

M2. The shifted solenoid valve (S) allows a small

amount of this return flow to return to tank through a

manifold sensing line which causes a pressure increase

that shifts brake cartridge LC2. Hydraulic flow is routed

through shifted LC2, out manifold port P2, through the

oil cooler and filter and then is routed to the gear pump

input. The deck m otor continues to rotate as long as so-

lenoid valve (S) is energized.

Deck motor case drain leakage returns to the hydraulic

reservoir.

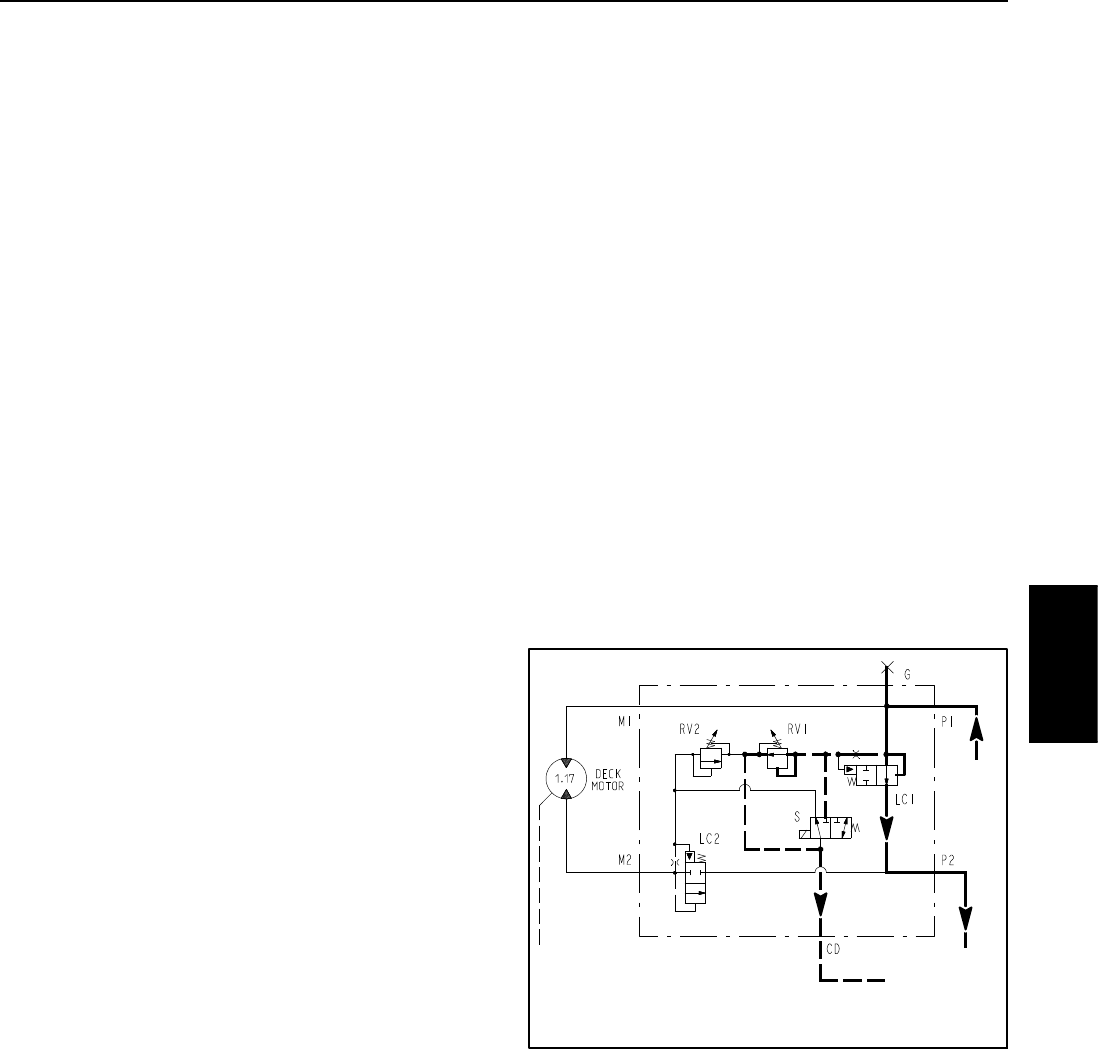

PTO Circuit Relief

Maximum mow circuit pressure is limited for each deck

by a relief valve (RV1) in the PTO manifold. The center

and left deck relief valves are set at 3000 PSI (207 bar)

and the right deck relief valve is set at 2000 PSI (138

bar).

Relief valve (RV1) and bypass cartridge (LC1) work to-

gether as a two stage relief. When increased circuit re-

sistance is met or if a cutting blade should strike an

object, the pressure increase is felt at the relief valve. If

the pressure should exceed the relief valve setting, the

relief valve will open, creating a small amount of hydrau-

lic flow to return to tank through a manifold sensing line.

This flow causes a pressure increase t hat shifts bypass

cartridgeLC1 and diverts circuit flow away from the deck

motor to manifold port P2 (Fig. 10). When circuit pres-

sure lowers, relief valve (RV1) closes which returns by-

pass cartridge LC1 back to its neutral position allowing

flow to return to the deck motor.

Figure 10

SOLENOIDSENERGIZED

RV1SHIFTED

LC1SHIFTED

DECKMOTORSTALLED

FRONTPTO

MANIFOLD

PUMPFLOW

RETURN

Hydraulic

System