Groundsmaster 4000--D/4010--D Hydraulic SystemPage 4 -- 119

5. Remove four (4) c ap screws (item 11) and washers

used to secure fan to fan hub. Remove fan.

IMPORTANT: Make sure to not damage the radiator

or other machine components while loosening and

removing the fan motor and bracket assembly.

6. Remove cooling fan motor and bracket assembly.

A. To prevent contamination of hydraulic system,

thoroughly clean exterior of fan motor and fittings.

B. Disconnect hydraulic hoses from fan motor. Put

caps or plugs on fittings and hoses to prevent con-

tamination. Label hydraulic lines for proper assemb-

ly.

C. Remove six ( 6) cap screws and flange nuts that

secure fan motor bracket to radiator.

D. Carefully remove fan motor and bracket assem-

bly from machine and place on suitable work sur-

face.

7. Remove hex nut (item 9) andwasher (item8) that se-

cure fan hubto fan motor.Use suitable puller to carefully

remove fan hub from fan motor shaft. Locate and re-

trieve woodruff key.

8. Remove two (2) cap screws (item 20), flat washers

(item 21) and lock nuts (item 14) that secure fan motor

to fan motor bracket. Remove fan motor from bracket.

9. If hydraulic fittings are to be removed from fan motor,

mark fitting orientation to allow correct assembly. Re-

move fittings from motor and discard O--rings.

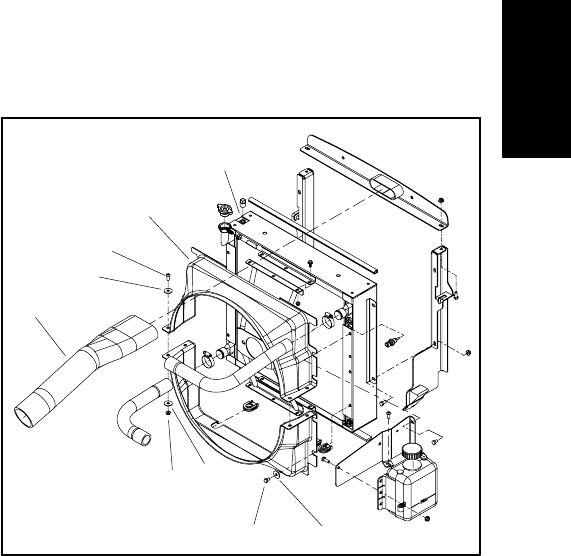

Installation (Fig. 89)

1. If fittings were removed fromfan motor, lubricate and

place new O--rings onto fittings. Install fittings into port

openingsusingmarks madeduringthe removalprocess

to properly orientate fittings. Tighten fittings (see Hy-

draulic Fitting Installation in the General Information

section of this chapter).

2. Position fan motor to fan motor bracket and secure

with cap screws (item 20), flat washers (item 21) and

lock nuts (item 14).

3. Thoroughly clean tapered surfaces of fan motor

shaft and fan hub. Place woodruff key in slot in motor

shaft.

4. Position fan hub onto motor shaft and secure with

washer (item 8) and hex nut (item 9). Torque nut from 27

to 33 ft--lb (37 to 44 N--m).

IMPORTANT: Make sure to not damage the radiator

or other machine components while installing the

fan motor and bracket assembly.

5. Carefully position fan motor andbracket assembly to

radiator and secure with six (6) cap screws and flange

nuts.

6. Remove caps and plugs placed in hoses and fittings

during removal to prevent contamination. Connect hy-

draulic hoses to cooling fan motor (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

7. Apply Loctite #242 (or equivalent) to threads of cap

screws (item 11) used to secure fan to fan hub. Position

fan to fan hub and secure with four (4) cap screws and

washers. Torque screws from 12 to 14 ft--lb (17 to 18

N--m).

8. Install upper radiator shroud and air cleaner hose

(Fig. 90). Make sure that clearance betweenshroud and

cooling fan is at least 0.180” (4.6 mm) at all points.

9. Lower and secure hood.

10.Make sure hydraulic tank is full.

11.Properly fill hydraulic system (see Charge Hydraulic

System in this section).

1. Radiator

2. Upper radiator shroud

3. Screw (4 used)

4. Flat washer

5. Air cleaner hose

6. Flange nut (4 used)

7. Cap screw

Figure 90

3

5

6

4

7

1

2

4

4

Hydraulic

System