Instruction Manual

748297-E

June 2003

Rosemount Analytical Inc. A Division of Emerson Process Management Installation

2-9

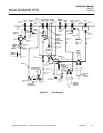

Model NGA2000 HFID

2-6 INSTALLATION CONSIDERATIONS

CHECKLIST

Verify the following:

• The Analyzer’s location should be:

Clean

A well ventilated area

weatherproofed

Non-hazardous

Vibration-free

Have stable ambient temperature

• The gas cylinders should be equipped

with a clean, hydrocarbon free two stage

regulator and shut off valve.

• All external tubing, regulators, valves,

pumps, fittings, etc. are clean.

• The correct fuel type is being used.

• The THC content of the supply gases

are compatible with the analysis range.

• The calibration background gases are

similar to the sample.

• The purge air out, burner exhaust, and

bypass are vented to atmospheric pres-

sure. The pressure should be constant.

• The burner exhaust tube must be

slanted down a minimum of 6 degrees

from horizontal.

• The bypass line connection must be

slanted down a minimum of 6 degrees

from horizontal for drainage of water

condensation.

• If required, thermal insulation around the

bypass fitting to prevent condensation in

the bypass restrictor.

• If required, thermal insulation for the

sample inlet connection to minimize the

cold spot.

• The heated line is at the correct tem-

perature.

• The sample, zero, and span gases are

at the correct temperature.

• The heated line to have over tempera-

ture protection.

• The sample, bypass, and burner ex-

haust tubing material must handle high

temperature and have thermal insulation

to protect from burns.

• The purge air out tubing to be 3/8 inch

and less than 4 feet in length.

• All external gas connections have been

leak checked.

• The dead volume for external sample

and fuel lines have been minimized.

• The stainless steel tubing used for the

fuel and sample lines is clean.