Instruction Manual

748297-E

June 2003

Installation Rosemount Analytical Inc. A Division of Emerson Process Management

2-4

Model NGA2000 HFID

introduced through the sample inlet at the

rear of the module.

Zero Gas - Analysis is affected by the

background gas of the sample. Therefore, it

is recommended to use zero gas with as

close to the background composition of the

sample as possible. Normally less than 0.5

THC as CH

4

is sufficient.

Span Gas - Span gas consists of a speci-

fied concentration of methane or other hy-

drocarbon in a background gas such as

nitrogen. Analysis is affected by the back-

ground gas of the sample. Therefore, span

gas containing the same background gas as

the sample is recommended. Then, the

background effect is canceled out.

h. Sample Gas Specification

Sample gas should be nonflammable (be-

low 100% of the sample's LEL). For high

sensitivity applications requiring background

gas compensation, contact the factory.

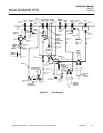

i. Flow Rate Specification

Required sample flow rate is 1.0 L/min. to

2.5 L/min. for a supply pressure between 5

and 9 psig. Flow rate for purge gas should

be 16 to 18 L/min. Flow rate for regulated

air should be 2 to 4 L/min.

j. Pressure/Filtration Specification

Sample Pressure at the SAMPLE inlet

should be within the range of 345 to 620

hPa-gauge (5 to 9 psig, 7.0 psig nominal),

and internally, should be between 206.7

and 275.6 hPa-gauge (3.0 and 4.0 psig).

Burner Fuel Pressure should be: 3101 to

3450 hPa-gauge (45 to 50 psig) for cylinder

regulator, 1723 hPa-gauge (25 psig)

nominal for internal pressure.

Burner Air Pressure should be : 1725

to 3450 hPa-gauge (25 to 50 psig) for

cylinder regulator, 1035 hPa-gauge (15

psig) nominal for internal pressure.

Regulated Air Pressure should be 689

to 1725 hPa-gauge (10 to 25 psig) for

cylinder regulator.

Purge Air Pressure should be 689 to

1380 hPa-gauge (10 to 20 psig).

Nominal Internal Case Pressure is

about 0.5 to 1.0 inch of water, and the

pressure relief valve is set at 1/3 psig

(nominal).

CAUTION

OVER-PRESSURE

Noncompliance with these specifica-

tions, particularly those concerning

purge air, could cause over-pressure

damage to the module.

Note

The sample gas and regulated air

should be filtered for particulates

down to 2 microns to prevent the

plugging of pneumatic components.

k. Leak Test

The analyzer module is completely leak

tested at the factory. The user is re-

sponsible for testing for leakage at the

inlet and outlet fittings on the rear panel.

The user is also responsible for internal

leak testing periodically and if any inter-

nal pneumatic components are adjusted

or replaced (with a test procedure cho-

sen by the user).