Instruction Manual

748297-E

June 2003

Installation Rosemount Analytical Inc. A Division of Emerson Process Management

2-2

Model NGA2000 HFID

All new external gas tubing (except for

PURGE IN/OUT and SAMPLE BYPASS) is

strongly recommended, preferably pre-

cleaned, stainless steel, gas chromato-

graph-grade tubing. Thoroughly clean be-

fore use (if a hydrocarbon-based cleaning

solvent such as acetone is used, purge tub-

ing with dry nitrogen or helium for several

minutes before using.)

Gas line connections are compression fit-

tings. Do not use pipe thread tape.

Since the oxidation of hydrogen is accom-

panied by the formation of water vapor, the

Exhaust tubing always should be slanted

downward at least 6 degrees from horizon-

tal. Otherwise, water may accumulate in

the line, causing back pressure and

noisy readings, or may back up in the

line and flood the burner. Depending on

the percent of water vapor in the sam-

ple, the sample bypass out connection

may have condensation. Proper drain-

age may be required.

If the sample is toxic or noxious, or is to

be reclaimed, connect the Bypass outlet

to a suitable disposal system. Do not

use any device that may cause back

pressure in the line.

Purge air and burner air should be sup-

plied from separate sources.

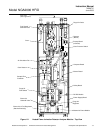

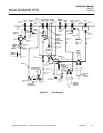

Figure 2-1. Back Panel Connections

Danger d'electrocution, d'explosion ou d'emanation de gaz

toxique. Se refere aux details inscrits surla face du module.

PURGE

AIR IN

PURGE

AIR OUT

PRESSURE

RELIEF

VALVE

BURNER

AIR IN

HEATED

SAMPLE IN

VENT TO SAFE AREA

SLOPE DOWNWARD 6!

MINIMUM

FUEL

IN

BURNER

EXHAUST

OUT

REGULATE

D

AIR IN

MAXIMUM

INPUT

PRESSURE

HEATED

SAMPLE

BYPASS OUT

Possible electric shock, explosion or toxic gas hazard. See front of module

A

TTENTION

FUEL: 50 psig(3445 hPa)

BURNER AIR: 50 psig (3445 hPa)

SAMPLE: 8 psig (551 hPa)

PURGE AIR: 20 psig (1378 hPa)

REG AIR: 25 psig (1722 hPa)

ATTENTION

WARNING

WARNING

CHAUD !

!

!

HOT !