Updated 23/05/07 RAOM0507 Apollo Bicycle Company Pty. Ltd. ABN: 60 001 914 469

51

Lubrication and Adjustment

The maintenance your pedals need will depend upon whether or not they can be

disassembled to enable access to the internal bearings and axle. If they cannot

be disassembled, every six months a small amount of oil should be injected onto

the inside bearings of pedals. Pedals that can be fully disassembled should have

the bearings removed, cleaned and greased every six to twelve months. However, due

to the complexity of this task it is recommended that it be completed by a professional

bicycle mechanic.

Attachment

Each pair of pedals has a specific right and left pedal. It is important that a pedal is

never forced into the incorrect crank arm as the thread is different for the two pedal sides.

The right pedal, as indicated by the “R” stamped on the end of the axle, screws into

the crank on the chainwheel side of the bicycle in a clockwise direction. The left pedal

is marked with an “L” on the axle, and it is attached to the other side in an

anti-clockwise direction.

To attach, place the pedals into the correct crank arm and wind on by hand as tightly

as possible in the appropriate direction. Use a 15mm wrench to fasten more securely.

Removing a pedal is the reverse process of attaching. The right pedals needs to be

turned anti-clockwise and the left, clockwise.

Before fitting any new pedals ensure that

the axle thread size is compatible with the

cranks on your bicycle. The two types

of cranks available each have different

axle threads. Cranks that are a one piece

design have no separate axle and are

compatible with pedals that have a 1/2”

thread. Three piece crank sets with a

separate left and right crank use a slightly

larger 9/16” thread.

WARNING:

Never attempt to force a pedal into a different sized bicycle crank.

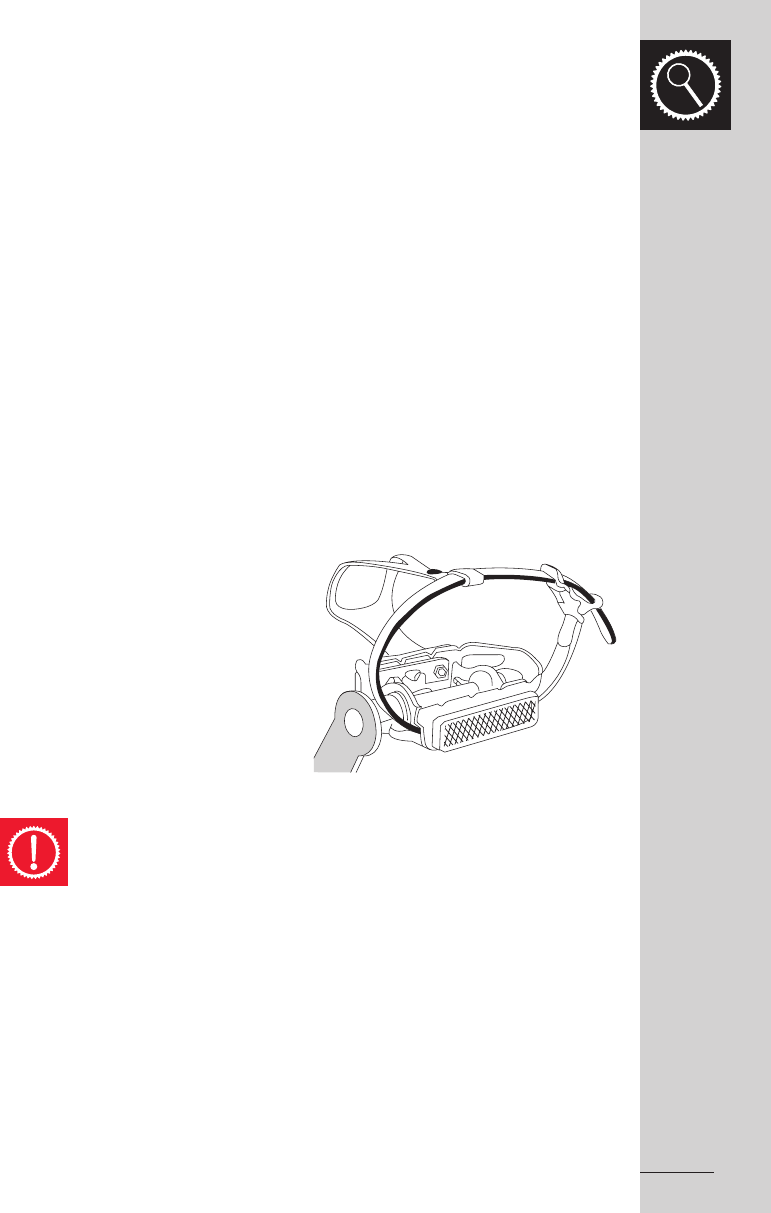

Pedal with toe clip and strap attached