46

www.seuservice.com

The items listed below require periodic check and maintenance to retain the performance of this machine and

ensure safe operation.

14. PERIODIC INSPECTION TABLE

Be sure to check once a year to see if Power Cords are damaged, the plug is securley inserted, dust

is accumulated between the Socket Outlet and the Power Plug, etc. Using the product with dust as

is accumulated can cause a fire or electrical shock.

Periodically once a year, request the place of contact herin stated or the Distributer, etc. where the

product was purchased from, as regards to the interior cleaning. Using the product with dust as is

accumulated in the interior without cleaning can cause a fire or short circuit accident. Note that

cleaning the interior parts can be performed on a pay-basis.

CLEANING CABINET SURFACES

If the cabinet is badly stained, use a cloth which is dipped in the chemical detergent liquid diluted with water and then

squezzed dry. Do not use thinner, benzine, alcohol or chemical dustcloth as these can damage Cabinet surfaces.

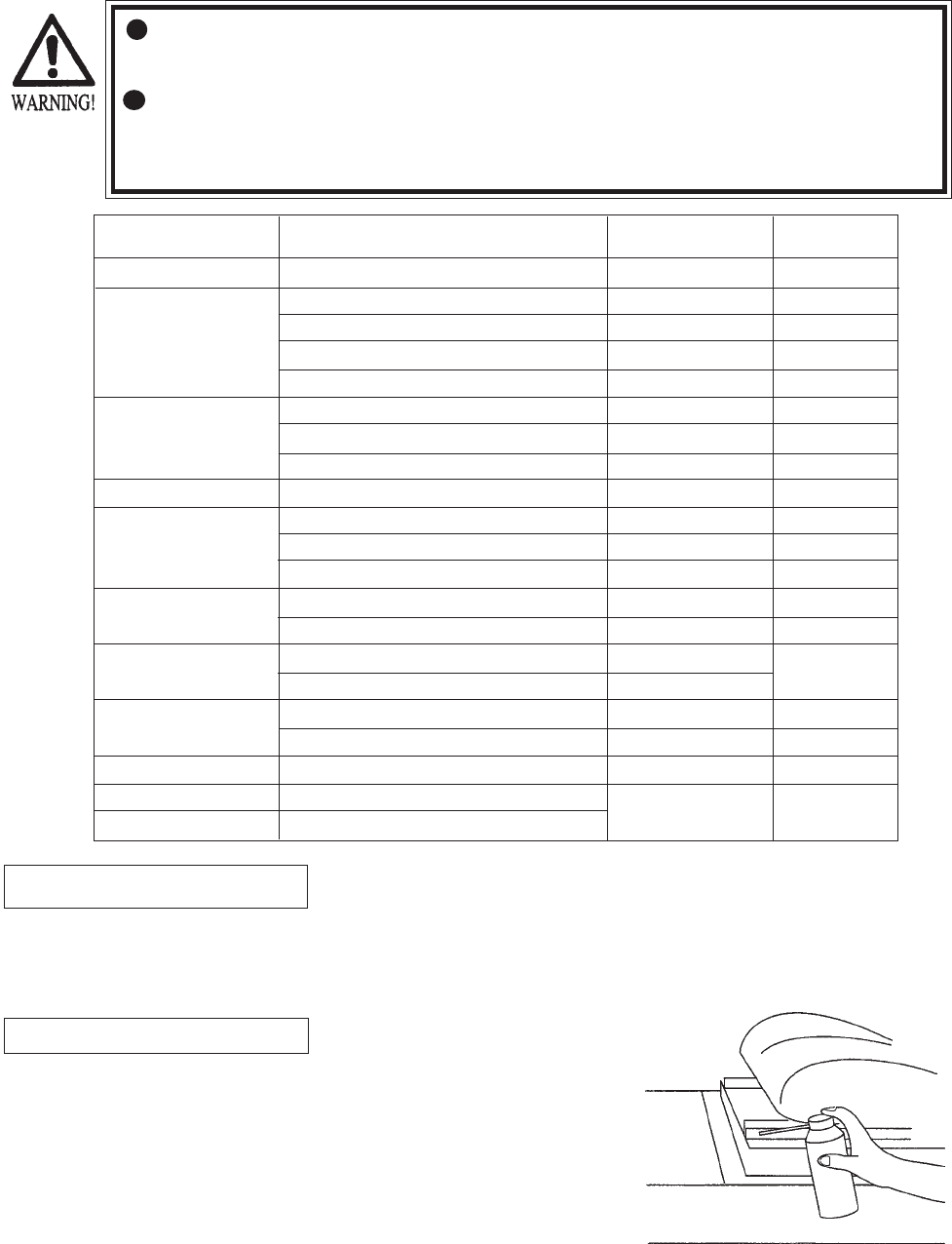

SEAT (Greasing to Seat Rail Portion)

Move the Seat to the rearmost portion and apply spray greasing to the

portion shown at the right once every 3 months by using NOK KLUBER

L60 or GREASE MATE SEGA PART No. 090-0066. After greasing, move

seat a few times forward and backward so as to allow the grease to be

applied all over uniformly. Be sure to wipe grease which attaches to the

surfaces of the PROTECT RUBBER on the seat Rail, or any excess grease.

INTERVAL

Daily

Monthly

Monthly

Tri-Monthly

Tri-Monthly

Monthly

Tri-Monthly

Tri-Monthly

Monthly

Monthly

Monthly

Tri-Monthly

Monthly or when moving

Weekly

Bi-Monthly

Tri-Monthly

Monthly

Monthly

As occasion arises

Annually

REFERENCE

4

8

8

9

9

10

10

10

9

4

11

11

12

12

Next page

7

7

Next page

See Above

CABINET

HANDLE MECHA

ACCEL. & BRAKE

SHIFT LEVER

COIN CHUTE TOWER

MONITOR

SEAT

GAME BD

CABINET SURFACES

INTERIOR

POWER SUPPLY PLUG

ITEM

Check Adjusters’ contact with surface.

Check lamp.

Check VOLUME VALUE.

Check ADJUST GEAR engagement.

Greasing of GEAR.

Check VOLUME value.

Check ADJUST GEAR engagement

Gear and Spring portion greasing.

Check Switches.

Check COIN SW.

Coin insertion test.

Cleaning of COIN SELECTOR.

Check adjustments.

Cleaning of CRT surfaces.

Antistatic measures.

Applying grease to Seat Rail.

MEMORY TEST.

Check Settings.

Cleaning

Cleaning

Inspection and cleaning.