-22-

M1036 Micro Mill

MAINTENANCE

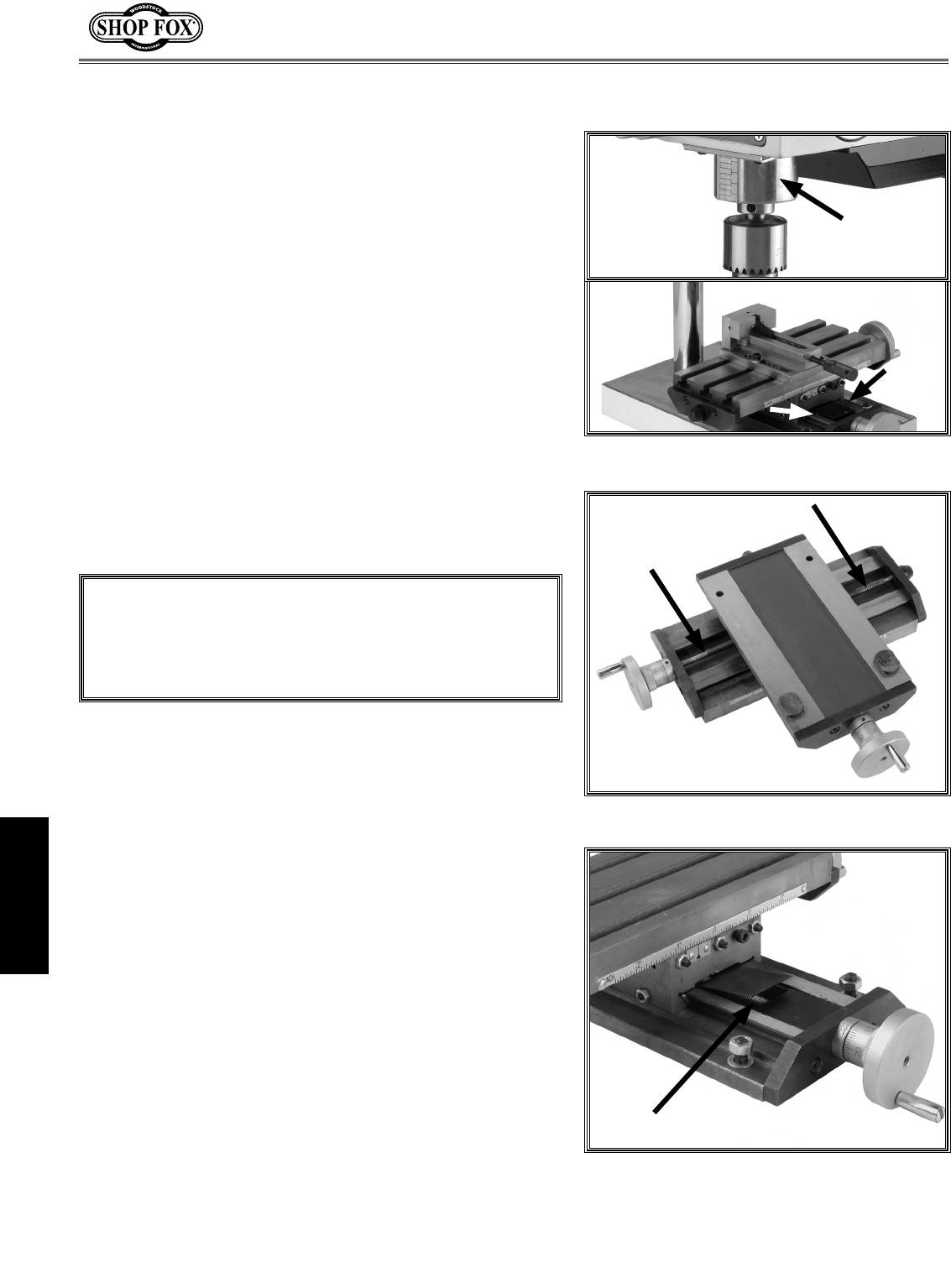

Regular lubrication will ensure your mill performs at its

highest potential.

Place two to three drops of

ISO 68 or SAE 20W non-deter-

gent oil or similar lubricant directly on the following

areas each time you use your mill (see Figure

26):

• Cross slide and saddle

ways

• Quill shaft

Apply a light weight lithium based grease directly to

these points once a month or more frequently as needed:

• Longitudinal leadscrew (Figure 27)

• Crossfeed leadscrew (Figure 28)

Note: Pry up the leadscrew cover to access the crossfeed

leadscrew.

Lubrication

Figure 26. Points of lubrication.

Figure 27. Longitudinal leadscrew.

Lack of lubrication causes poor machine perfor-

mance. Keep your mill lubricated to reduce wear on

parts and discourage oxidation.

NOTICE

Figure 28. Crossfeed leadscrew.