-16-

M1036 Micro Mill

OPERATIONS

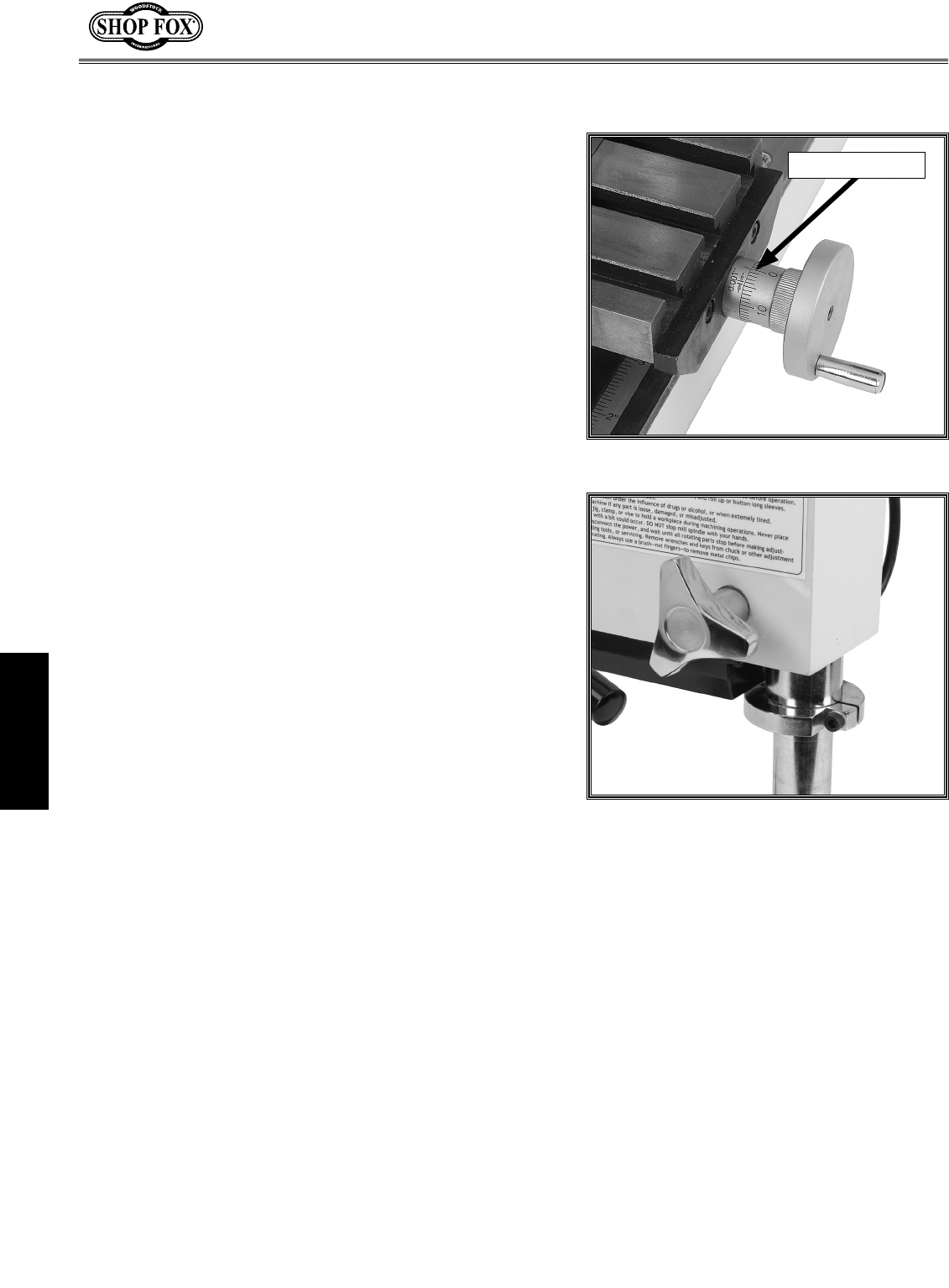

Each mark on the handwheel graduated dials (Figure 12)

represents 0.001" of movement. One full rotation of the

handwheel is equal to 0.050". The graduated dials can be

"zeroed" by grasping the knurled

section and rotating the

graduated dial to "0"

.

Example:

To drill a series of holes with

1

⁄2" centers (0.500"), drill

the first hole, zero the graduated dial, move the table

0.500" (10 rotations of the handwheel) in the appropriate

direction, then drill the next hole.

Graduated Dials

Figure 12. Graduated dial.

Graduated Dial

When changing table direction in either axis, the

handwheel will rotate a few degrees before the table

begins to move and the graduated dial must be adjusted.

This is backlash.

To correct for backlash, do these steps:

1. Turn the handwheel in the opposite direction of your

next operation.

2. Turn the handwheel to move the table in the intend-

ed direction

.

3. When the lead screw catches and the table begins to

move, backlash has been eliminated and the gradu

-

ated dial can be "zeroed."

Note: You will not need to adjust for backlash as

long as the table moves in the same direction.

Backlash

Adjusting the height of the headstock, instead of extend-

ing the quill, maintains the rigidity of the mill and

requires less motion when using the downfeed lever.

To adjust the headstock height, do these steps:

1. Loosen the collar (Figure 13) and lower it to the

desired height

.

2. Loosen the column lock knob and carefully lower the

headstock until it rests on the collar spacer

.

Note: Raise the headstock by reversing Steps 1 & 2.

Headstock Height

Figure 13. Headstock height adjustment.