© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Operation

AJ0975

20

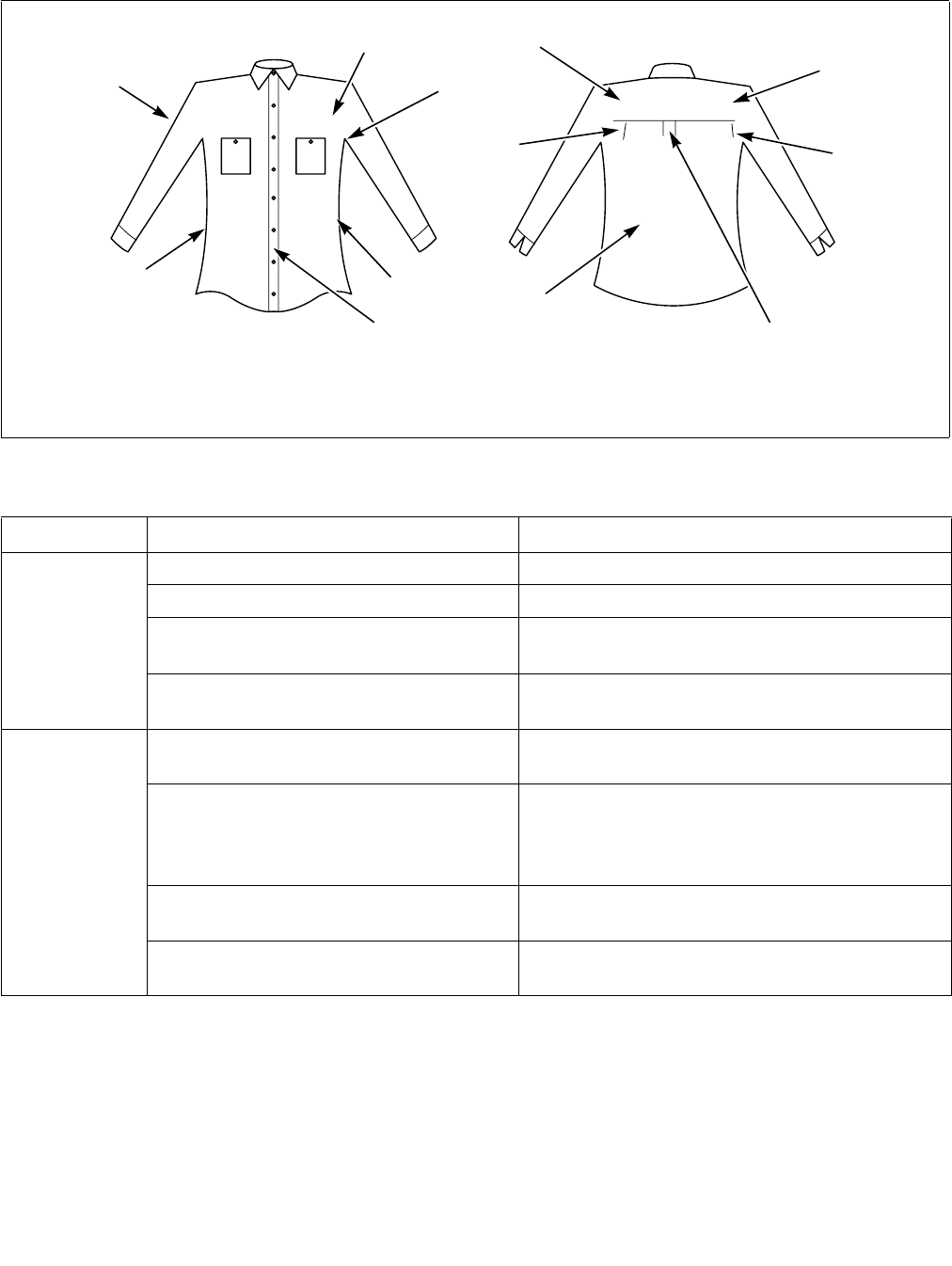

Quality Troubleshooting

Figure 20

Refer to Figure 20.

CAB263N

CAB263N

SHIRT QUALITY

1

1

4

3

2

3

7

5

5

7

6

4

Trouble Probable Cause Solution

Damp patches

on sleeve

(item 1)

1. Cycle time too short. Increase Timer.

2. Boiler pressure too low. Adjust pressure.

3. Faulty trap or check valve in steam return

line from condensate tank.

Clean, repair or replace faulty trap or check valve.

4. Steam supply coming from bottom of

header, no riser.

Correct inlet piping. Refer to Installation Manual.

Placket bowing

at the button

strips (item 2)

1. Operator pulling shirt too tightly on buck. Dress shirt so it hangs in natural “A.” Refer to Buck

Dressing Instructions.

2. Shirt not held in place by vacuum. Fan or draft in plant blows shirt during transfer.

Redirect fan. Close window or door which causes draft.

Check for hole or collapsed hoses. Flannel padding is

too thick. Install thirty ounce (30 oz.) flannel padding.

3. Air remains in side air bags at end of

pressing cycle and distorts shirts.

Damper to heat exchanger is not closing off or is not

closing off soon enough. Adjust as necessary.

4. Air to side air bags distorts shirt before

heads begin to press.

Adjust high pressure air to buck air bags.

Table 2 (Continued)