© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Operation

13

AJ0975

CSBBYMV Operation Sequence

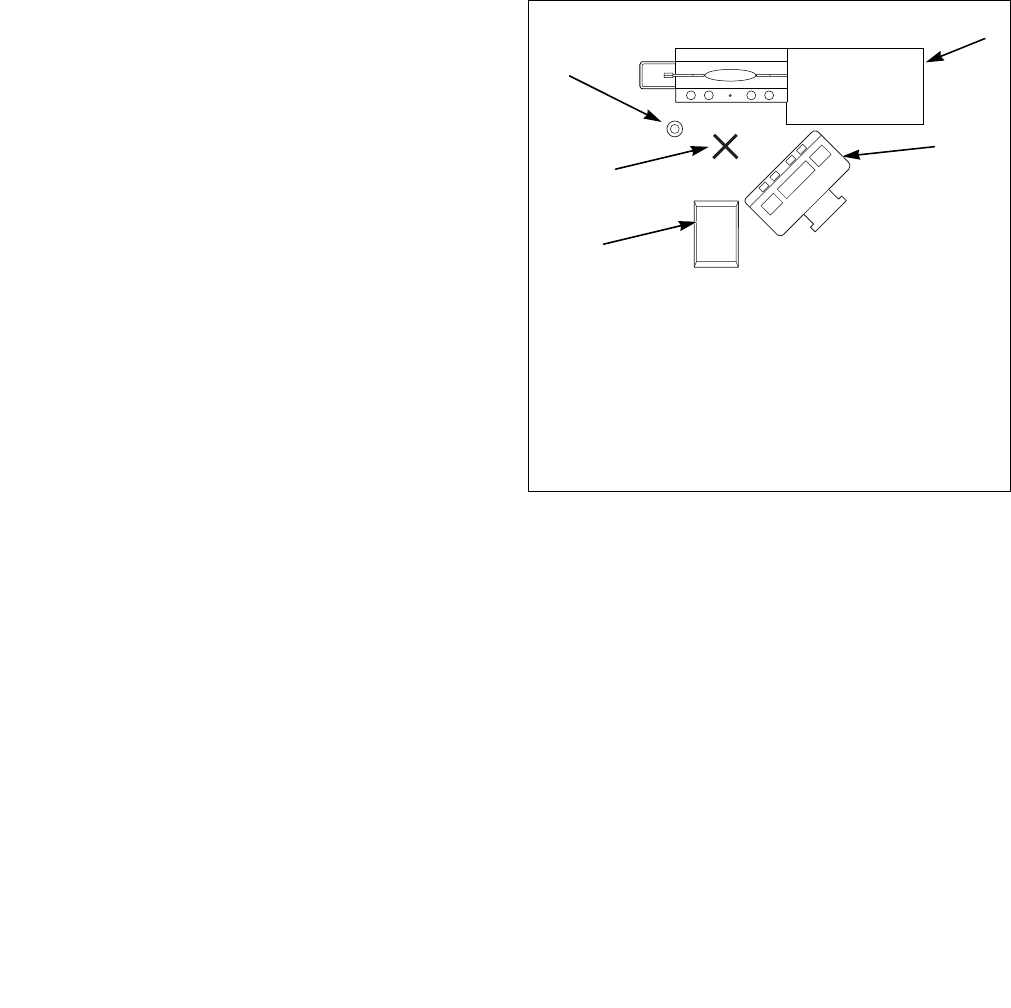

Single Operator. Refer to Figure 4.

A typical single operator shirt station consists of:

● One CSBBYMV sleeve, bosom, body and yoke

press

● One collar and cuff press (CUCC)

● One collar post

● One damp box

To increase operator productivity (with less fatigue)

position the items listed above as shown in

Figure 4.

Set timers as follows:

● Steam timer – 5 seconds

● Cycle timer – 35 seconds (100% cotton)

● Cycle timer – 25 seconds (Blends)

NOTE: Pressing and steam times may vary based

on:

● Steam pressure at the press. Ideally, steam

pressure at press should be 105-115 psi

(7.24-7.93 bar).

● Shirt fabric (100% cotton, blends, etc.).

● Fabric thickness and weight.

● Moisture retention in shirts should be 40% to

50%.

The sequence begins by removing a shirt from the

damp box and dressing it on the collar and cuff press.

As this shirt progresses COUNTERCLOCKWISE

through the station, other shirts will also be introduced

until there is a shirt at the collar post, the CSBBYMV

and the CUCC. The operator will then move in a

CLOCKWISE direction to keep shirts in all three

operations simultaneously.

The operation sequence for the CSBBYMV is:

1. Load shirt 1 from damp box onto CUCC.

2. Unload CUCC. Hang shirt 1 on garment hook.

3. Load shirt 2 from damp box onto CUCC.

4. Load shirt 1 from garment hook onto buck.

5. Unload CUCC. Hang shirt 2 on garment hook.

6. Load shirt 3 from damp box onto CUCC.

7. Remove shirt 1 from buck. Place on collar post.

Form collar and button. Leave shirt on collar post

to cure.

8. Load shirt 2 from garment hook onto buck.

9. Unload CUCC. Hang shirt 3 on garment hook.

10. Load shirt 4 from damp box onto CUCC.

11. Hang shirt 1 from collar post on finished rack.

12. Unload shirt 2 from buck. Place on collar post.

Repeat steps 7 through 12.

Figure 4

CAB416N

1 Collar Post

2 CSBBYMV

3 CUCC

4 Damp Box

5 Operator

CAB416N

TYPICAL CSBBYMV LAYOUT

1

3

4

2

5