Test Procedures

DDRRIIVVEE MMOOTTOORR TTEESSTT

This test is used in conditions of No Belt Movement.

Unplug treadmill and set voltmeter to Volts DC

Disconnect motor leads from PWM

Place 1 voltmeter lead in each motor wire

Gently spin motor flywheel and check for Voltage DC

2-5 Vdc means normal motor operation

0 Vdc means motor malfunction

DDRRIIVVEE BBEELLTT TTEENNSSIIOONN TTEESSTT

This test is used in front roller replacement and in conditions of Belt Slipping.

Place two fingers on top of drive belt halfway between front roller and drive

motor pulley.

With moderate pressure push down on belt.

If belt deflects down more than 1/4”, tighten motor mount bolts

If belt deflects down less than 1/4”, loosen motor mount bolts

3-30

Test Procedures

3-29

SSPPEEEEDD SSEENNSSOORR TTEESSTT

This test is used to verify sensor operation in conditions of Speed Fluctuation,

E2: Cal error, S4: Sensor error, E2: Overspeed error, or Unsuccessful Calibration.

In calibration mode before pressing Start, the treadbelt can be moved

manually and the Met light will blink when a magnet is in front of sensor.

Check sensor on all magnets.

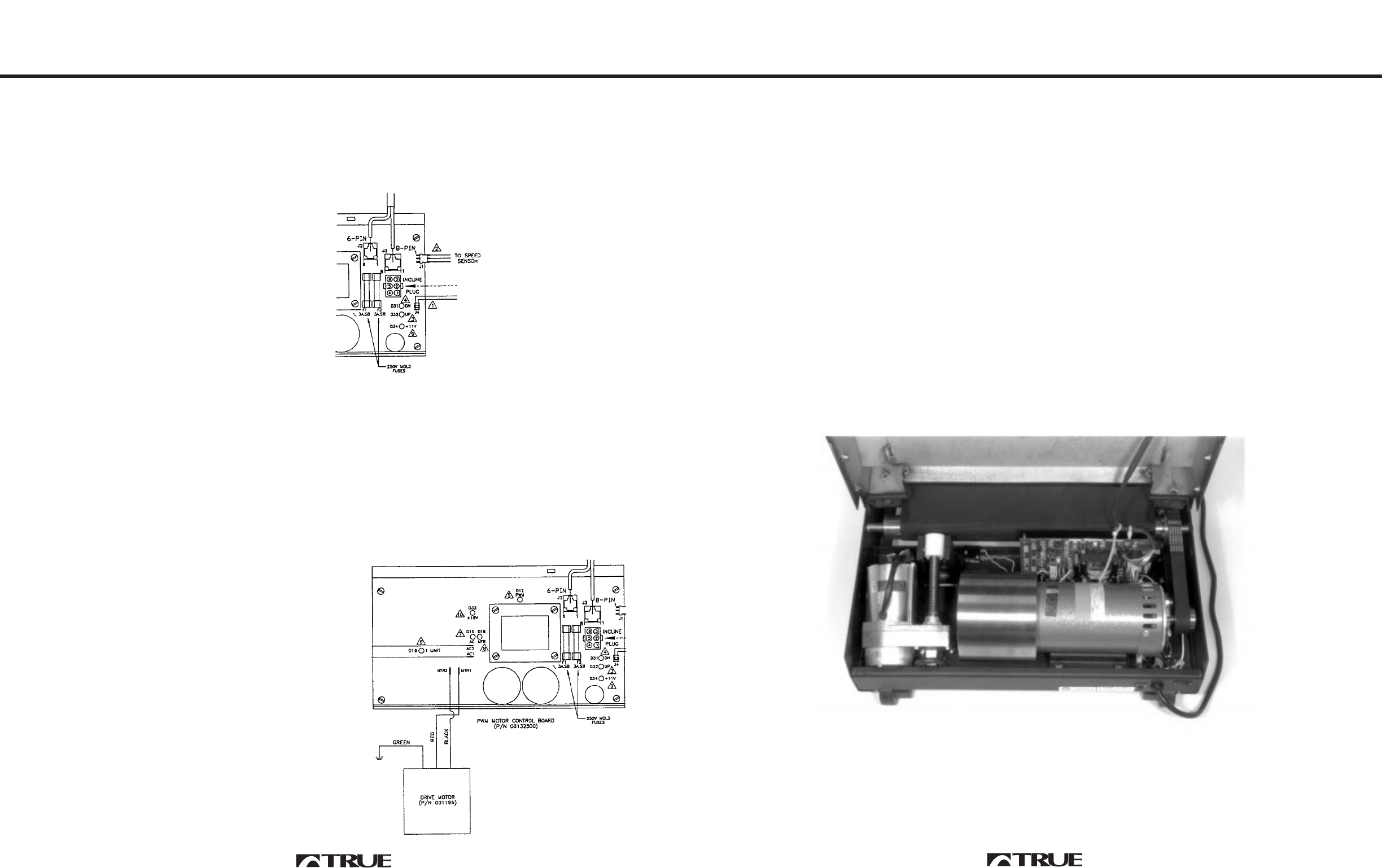

VVOOLLTTAAGGEE TTOO DDRRIIVVEE MMOOTTOORR TTEESSTT

This test is used to diagnose conditions of No Belt Movement, or Speed

Fluctuations

Set voltmeter to Volts DC and adjust speed on Control Panel to 4mph

Attach red voltmeter lead to MTR1 on PWM with motor wires attached

Attach black voltmeter lead to MTR2 on PWM with motor wires attached

0 Vdc signals no PWM output

166 Vdc signals open circuit in motor or motor connection

Operating voltage will lay between 0Vdc and 166 Vdc

NOTE: The reason that we do not narrow down PWM output voltage is that the PWM output

is a pulse signal. The sampling rate of the voltmeter used will determine what output voltage

the voltmeter is able to read.