29

Nautilus® Sport Series Treadmill Service Manual

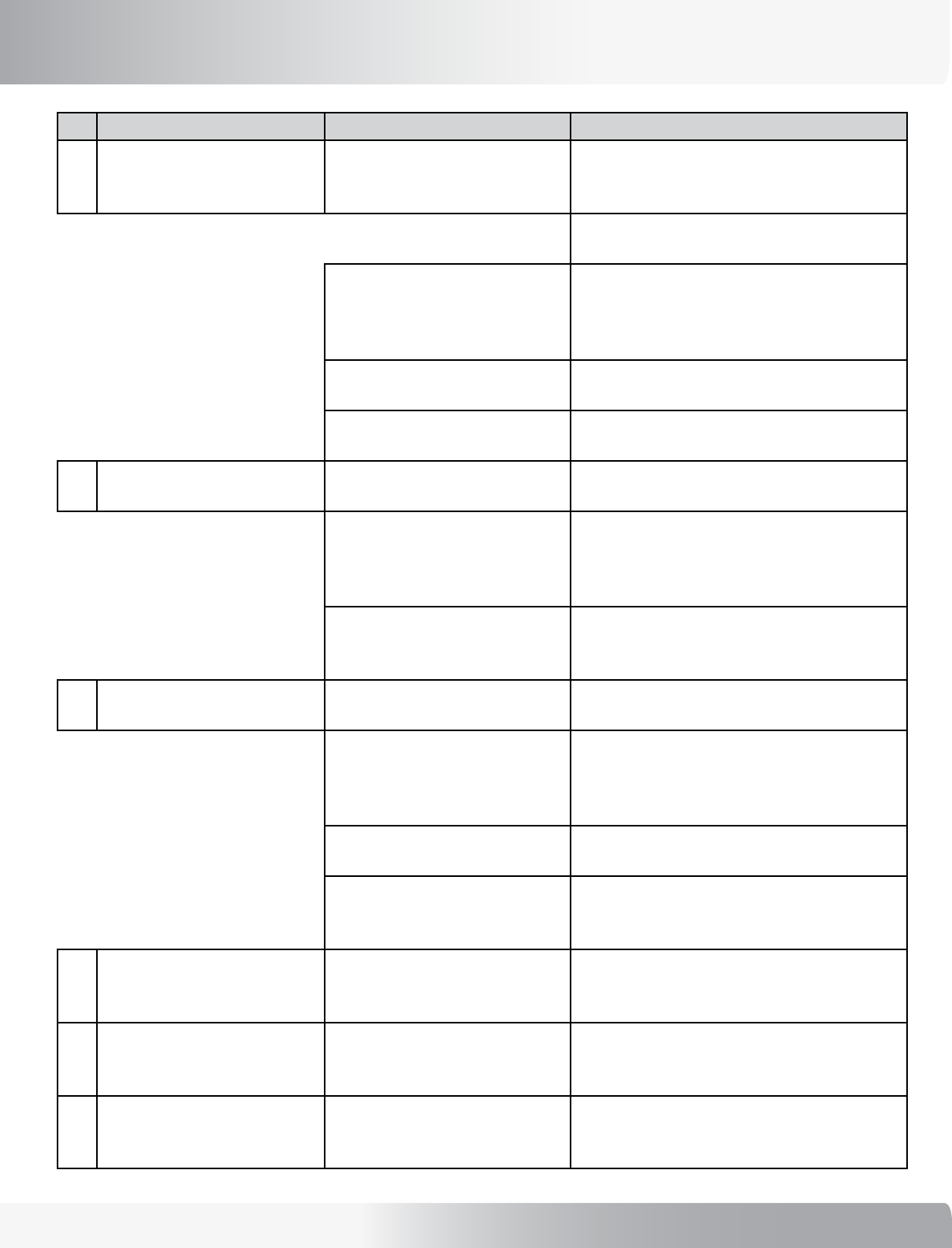

ELECTRICAL AND MECHANICAL TROUBLESHOOTING GUIDE

Condition / Problem Things to Check Solution

1. Knocking noise under the

motor cover or at the rear

of the treadmill.

Front and rear roller Let the rollers run for a week. Sometimes

bearings will seat and quiet down.

Roller continues to knock, replace the

roller.

Running belt tension If running belt is overtightened, it will put

excessive load on roller bearings. Loosen

roller adjustment bolts and check for

slippage.

Flywheel / Pulley on

applicable motors

Tighten set screw (5/32) on flywheel /

pulley.

white 6 inch fan on applicable

motors

Make sure that the 6 inch fan is not hitting

anything.

2. Chirping or squeaking

noise under motor cover.

Drive Belt Alignment Adjust the motor pulley and align with

roller pulley.

Drive Belt Grooves Remove drive belt and check grooves in

belt for foreign matter or debris. Clean

and/or replace belt. Clean drive motor

pulley and roller pulley grooves.

Motor Brushes on T516 or

T518 units only

Remove and inspect the motor brushes.

Sand brush surface and clean commutator

surface and reinstall.

3. Walking belt slips.

Walking Belt Tension Tighten walking belt tension.

NOTE: Do Not over tighten walking belt.

Drive Belt Tension Loosen the 4 motor bolts and then

tighten the drive belt adjustment bolt,

(approximately 2-3 turns) then re-tighten

the 4 motor bolts.

Belt/Deck Lubrication Spray with NAPA 8300®, Pyroil Silicone®

Lubricant or Lube-N-Walk®

Deck Surface Check the deck surface and make sure

the surface is in good condition and not

worn.

4. Walking belt hesitates

or seems to stick when

stepped on.

Walking Belt Tension Is the walking belt overtightened? Loosen

the walking belt adjustment bolts at the

rear roller. Check for slippage.

5. Speed loss when treadmill

is walked on.

Belt/Deck Lubrication Lubricate belt/deck with Napa 8300®

or Pyroil Silicone® lubricant or Lube-N-

Walk®.

6. Motor is making high

pitched noise (T516 or T518

models)

Motor Brushes Remove and inspect motor brushes. Sand

brush surface and clean the commutator

and reinstall the brushes.