ABS-PRC001-EN4

Features and

Benefits

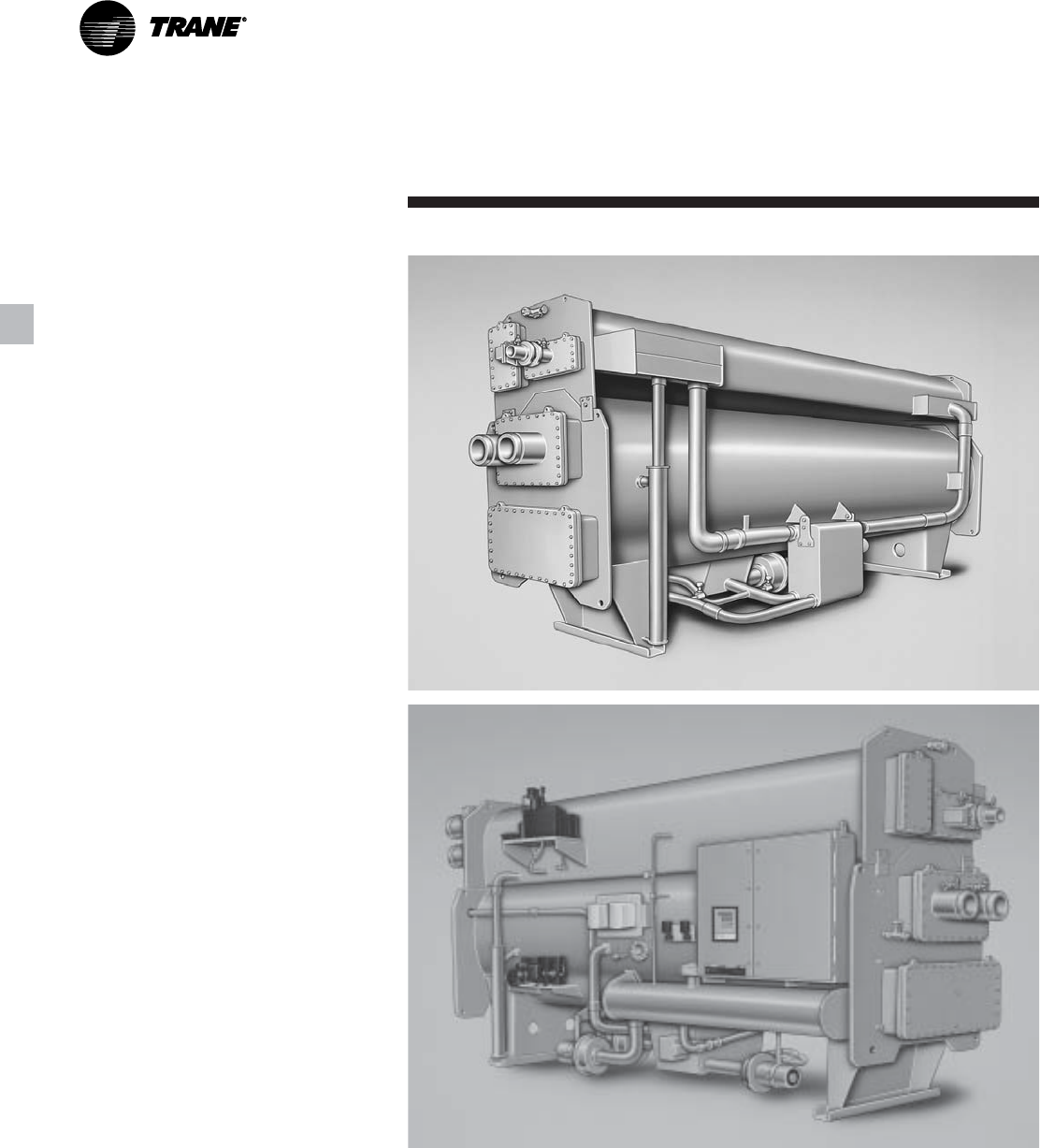

General

Trane Horizon

®

Absorption

Series, Single-Stage Hot

Water- or Steam-Fired

Absorption Water Chillers,

500-1350 Tons

Technology You Can Trust

In the early 1990’s, with the assistance of

the Gas Research Institute, Trane began

developing an innovative series of

absorption chillers. In 1995, Horizon

chillers began shipping from the Trane

manufacturing facility in La Crosse,

Wisconsin. The Horizon chiller is so

advanced, it redefined industry

standards for absorption system

integrity. Horizon chiller performance,

efficiency and reliability far exceed that

of past and present absorption chillers.

Dynamic By Design

Because uninterrupted chiller service is

critical to your operation, Horizon chillers

are designed to make chilled water

reliably, even in the harshest industrial

application. Water-tower systems and

load requirements can challenge the

long-term operation of many standard-

grade chillers. The industrial-grade

construction of the Horizon chiller

accounts for varying load and water-

temperature changes, as well as dirty

tower water. They are built with

corrosive-resistant alloy metals, and

precision welded in an ISO 9001 quality-

certified facility. Only extended-life

pumps, valves and water boxes are

manufactured into their design. For

further dynamics, Horizon UCP2

adaptive microprocessor controls react

precisely to system diversification.

Quality construction, long-life

components and adaptive controls are

what make the Horizon dynamic by

design.

Operates With Energy-Saving,

Low-Pressure Steam or Hot Water

The Horizon family includes a single-

stage, hot water- or steam-fired chiller

line. Able to produce chilled water in the

range of 40 to 60°F [4.4 to 15.6°C], these

machines use 12 psig [0.83 bar] low-

grade steam or 270°F [132°C] hot water.

Making chilled water from these

comparatively low-temperature inputs is

particularly important for energy

conserving applications, such as waste-

heat recovery, co-generation equipment

and solar-energy-powered cooling.

Using refrigerant water helps eliminate

refrigerant management or availability

concerns. Additionally, absorption

technology reduces the use of electric

energy.