ABS-PRC001-EN34

Job Site

Connections

Steam Supply and

Condensate Piping

Steam Supply

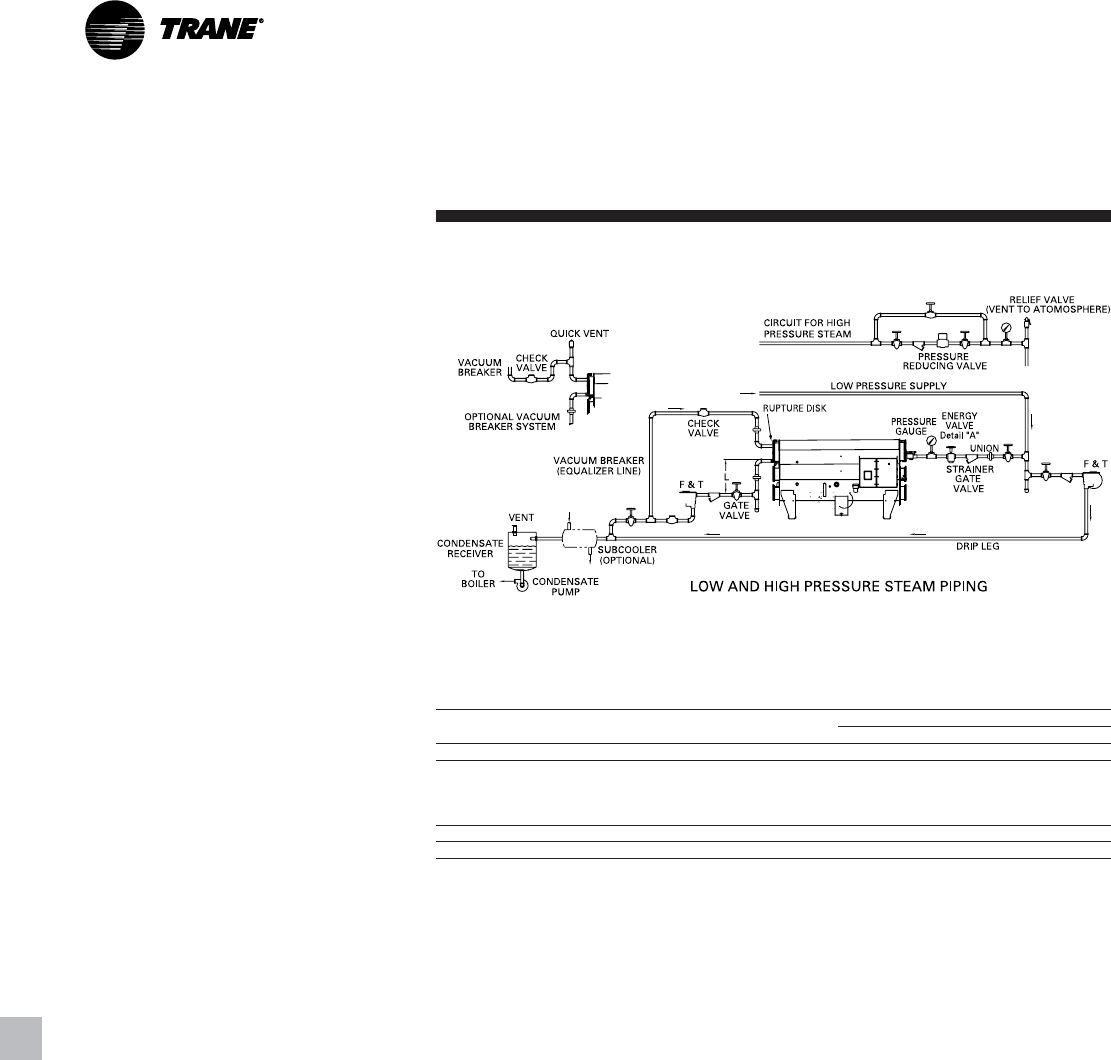

Figure JC-1 illustrates a typical steam-

supply piping illustration that includes

the appropriate hardware.

The steam supply piping should be

designed in accordance with good

design practice, providing strainers,

unions and gate valves for ease of

operation and maintenance. A properly

sized steam-modulating valve, based on

design flow and pressure drop

requirements, is provided by The Trane

Company.

A hand valve in the steam supply piping

is recommended when the machine will

be out of operation for an extended

period. The modulating steam valve

may experience a small amount of

leakage during shutdown. This leakage

may result in heating of the equipment

room unless the machine is properly

isolated with a hand valve.

In all applications, it is recommended

that the steam supply pressure to the

control valve inlet not exceed design to

ensure that the valve closes properly. If

steam supply pressures exceed design, a

pressure reducing station should be

used to control the steam pressure to the

valve.

The unit control has adjustable features

that minimize steam draw on start-up.

The adjustable steam-control feature

allows the user to adapt the machine to

the available steam source capability.

Table JC-1. Steam supply and condensate return piping responsibilities

Material Provided By Installed By

Item Trane Other Trane Other

Energy Valve X X

T-Type Strainer, Flanged connections, gate valve, drip leg

w/dirt pocket, float and thermostatic trap, pressure gauge vent X X

and valve, pressure reducing valve, pressure gauge, relief valve

check valve, connecting piping.

Rupture Disk Assembly X X

Rupture Disk Piping X X

Figure JC-1. Typical steam supply piping