Installation

InstallationInstallation

Installation

Installation of this equipment involves potentially

hazardous procedures. Only trained and qualied

personnel who have read and who understand

the information in this manual should install this

equipment.

LocationLocation

Location

When selecting the location for the equipment, keep

the following in mind:

• There must be sufcient space on all sides of

the equipment for installation, operator access,

maintenance, and air circulation.

• Ensure that the mounting surface and mounting

hardware are strong enough to support the weight

of the equipment, uid, hoses, and stress caused

during operation.

• There must be a start/stop control (C) within easy

reach of the equipment. See Fig. 1.

MountMount

Mount

thethe

the

PumpPump

Pump

See Mounting Hole Patterns, page 23.

Secure the stand to the oor with M19 (5/8 in.)

bolts which engage at least 152 mm (6 in.) into the

concrete oor to prevent the pump from tipping.

Level the pump as required, using shims.

PowerPower

Power

SupplySupply

Supply

RequirementsRequirements

Requirements

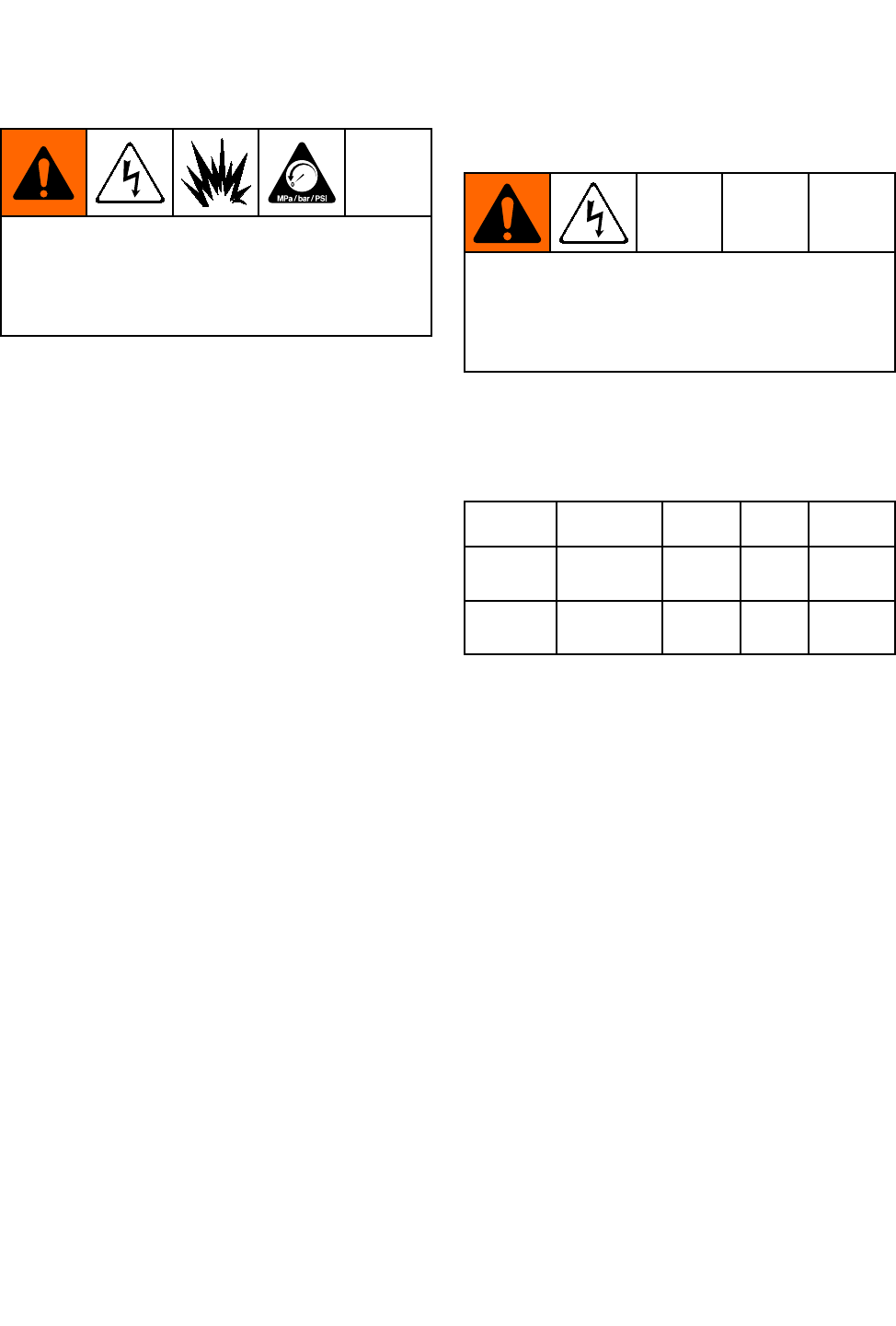

Improper wiring may cause electric shock or other

serious injury if work is not performed properly.

Have a qualied electrician perform any electrical

work. Be sure your installation complies with all

National, State and Local safety and re codes.

See Table 1 for power supply requirements. The

system requires a dedicated circuit protected with a

circuit breaker.

TableTable

Table

11

1

..

.

PowerPower

Power

SupplySupply

Supply

SpecicationsSpecications

Specications

ModelModel

Model

VoltageVoltage

Voltage

PhasePhase

Phase

HzHz

Hz

CurrentCurrent

Current

EM0011

EM0012

100–250

Vac

1 50/60 20 A

EM0021

EM0022

200–250

Vac

1 50/60 20 A

HazardousHazardous

Hazardous

AreaArea

Area

CablingCabling

Cabling

andand

and

ConduitConduit

Conduit

RequirementsRequirements

Requirements

ExplosionExplosion

Explosion

ProofProof

Proof

All electrical wiring in the hazardous area must be

encased in Class I, Division I, Group D approved

explosion-proof conduit. Follow all National, State,

and Local electric codes.

A conduit seal (D) is required within 18 in. (457 mm)

of the motor for the US and Canada. See Fig. 3.

All cables must be rated at 70°C (158°F).

FlameFlame

Flame

ProofProof

Proof

(ATEX)(ATEX)

(ATEX)

Use appropriate conduit, connectors, and cable

glands rated for ATEX II 2 G. Follow all National,

State, and Local electric codes.

All cable glands and cables must be rated at 70°C

(158°F).

83A2096D