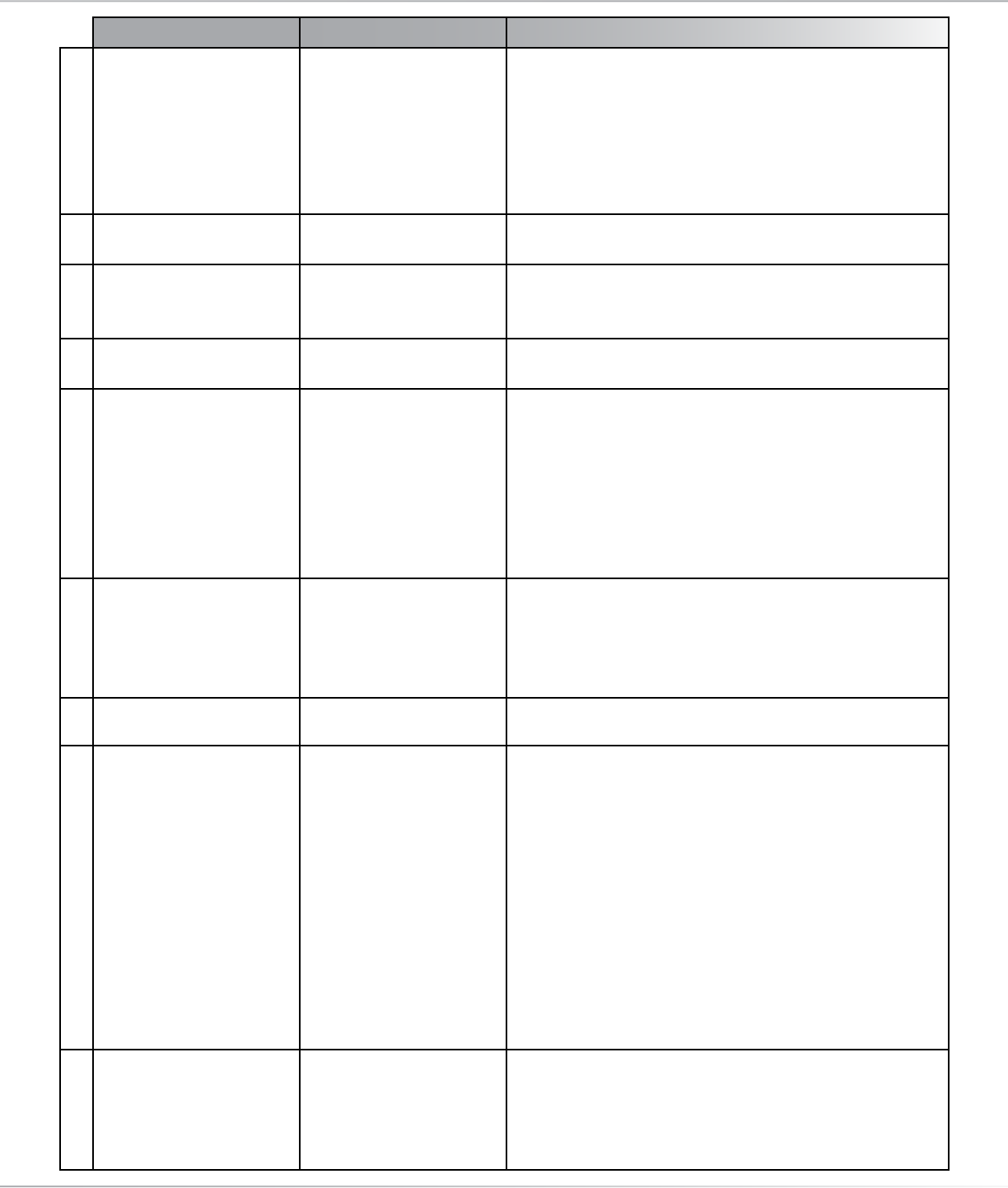

CONDITION/PROBLEM THINGS TO CHECK SOLUTION

Drive pulley and flywheel

pulley.

Unplug power from Unit. Wait at least 5 minutes. Remove

left side plastic drive cover to expose “v” belt drive line.

Using a ½” wrench, tighten the bolt that attaches the 4

½” drive pulley to the drive shaft while holding the drive

rollers still. Also, using a 5/32” hex wrench, tighten the

setscrew on the flywheel motor pulley. Reinstall plastic

drive cover.

Rear roller. If knocking sound seems to be coming directly from the

rear roller, replace.

Hydraulic cylinder bolts. Unplug power from Unit. Wait at least 5 minutes. Check

and tighten both upper and lower bolts that connect the

hydraulic cylinders to the unit.

Front rollers. If knocking sound seems to be coming directly from one or

both of the front rollers, remove and replace rollers.

Virtual pivot. Access the virtual pivot by removing the rear step plastic

and rear step. The virtual pivot will be under the rear roller

and has 2 brackets (one on each treadle, which rolls on 4

cam followers (large bearings). Make sure all 4 brackets

are rolling (turning) as the treadles pivot. If knocking/

squeaking is coming from the virtual pivot or if any of the 4

cam followers are not rolling the virtual pivot (also referred

to as "Bearing Roller Kit") should be replaced.

Treadle alignment If treadles are not centered between the uprights and

are contacting one of the uprights check if treadles are

parallel. If not adjust virtual pivot. If treadles are parallel

but are still contacting an upright entire machine must be

replaced.

7

Belts stop turning and "err

LS" or "err OS" is displayed

Calibration Re-calibrate machine. (See Calibration Procedures, Pg 26)

SPEED SENSOR

1. Cycle power off and on

2. Put the machine in calibration mode (see Calibration

procedures, Pg 26) but do not start the calibration routine.

3. Remove right rear base plastic cover to allow access to

LED board. Caution: Machine is on. Current is active!!

4. Locate LED D on the motor controller board. LED may

be lit or unlit.

5. Manually advance the treadle with your foot, and check

if LED D is blinking.

6. If LED D is not blinking, then the speed sensor is not sup-

plying a signal. Check that the speed sensor is connected

securely to P1 on the motor controller. If sensor is con-

nected and LED D still does not flash replace sensor.

I/O cables If LED D is flashing when the belts are turning but err LS

or OS persists, check for signs of visible damage to any of

the three I/O calbes and connections. If no visible damage

check continuity using a multi-meter. If a multi-meter is

not available replace all three cables.

TROUBLE SHOOTING GUIDE

63

Bowflex® TreadClimber® Owner’s Manual