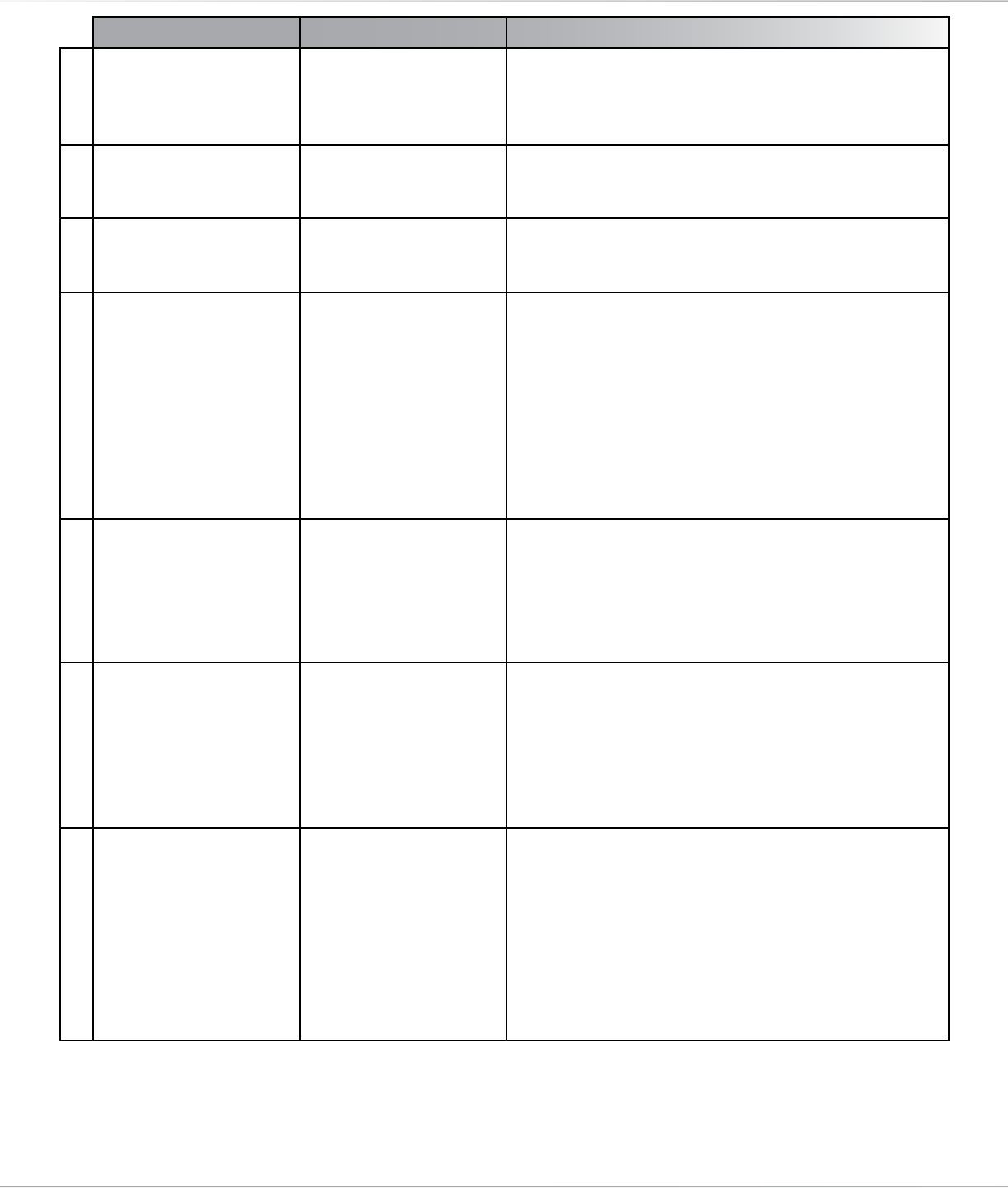

CONDITION/PROBLEM THINGS TO CHECK SOLUTION

HR receiver. If chest strap is known to work with other devices and

no sources of interference are present, or if console has

been tested with a Pulse Simulator and is not receiving the

signal, replace the HR receiver and wire.

4

Walking belt

misalignment.

Tracking adjustmen If either of the walking belts seem to be tracking

excessively to one side or the other adjust belt at front of

each treadle (see Walking Belt Adjustment, Pg. 9)

Roller shaft bracket If belt adjustments don't correct misalignment replace

both belts and either or both roller shaft bracket

depending on which belt(s) aren't aligning.

5

Hesitation or belt slipping

when walking on unit.

Belt tension If belt hesitates or slips when walking on unit it may be

caused by either a loose walking belt or a loose drive belt.

To determine the cause perform the following test:

Stand beside TreadClimber® fitness machine and set

speed to 2 MPH. Step on one treadle and attempt to stop

movement. If one belt stops but roller at rear and other

belt continues to turn, walking belt tension should be

adjusted. If both belts stop but motor is still turning the

drive belt tension should be adjusted.

Drive belt. Unplug power from unit. Wait 5-minutes to ensure no

residual power remains. Remove rear base plastic cover

to expose “v” belt drive line and motor. Tighten nut on the

motor tension bolt located on front side of motor in 1/2 turn

increments until drive belt slippage is eliminated - DO NOT

OVER TIGHTEN. Reinstall rear base plastic cover

6

Knocking / squeaking

noises when unit is

operating.

Upper linkage bolts. Unplug power from Unit. Wait 5-minutes to ensure no

residual power remains. Located on the underneath side

of each treadle there are bolts, one per side, that connect

the treadles to the linkage arms. Push right treadle down

to access left treadle and vice versa. Using a 9/16”

wrench and Allen key, make sure these bolts are securely

tightened.

Lower linkage bolts. Unplug power cord from rear of unit. Wait 5-minutes to

ensure no residual power remains. Push the right treadle

all the way down to access left teeter bolt. You will see a

linkage system near the middle of the unit that ties the two

treadles together. On the left side of the linkage pivot, you

will see a bolt that connects the linkage arms to the pivot.

Using a 9/16” wrench and an Allen key, make sure that

bolts are securely tightened. Push the left treadle all the

way down and repeat for right side

TROUBLE SHOOTING GUIDE

62

REPAIRS/MAINTANENCE