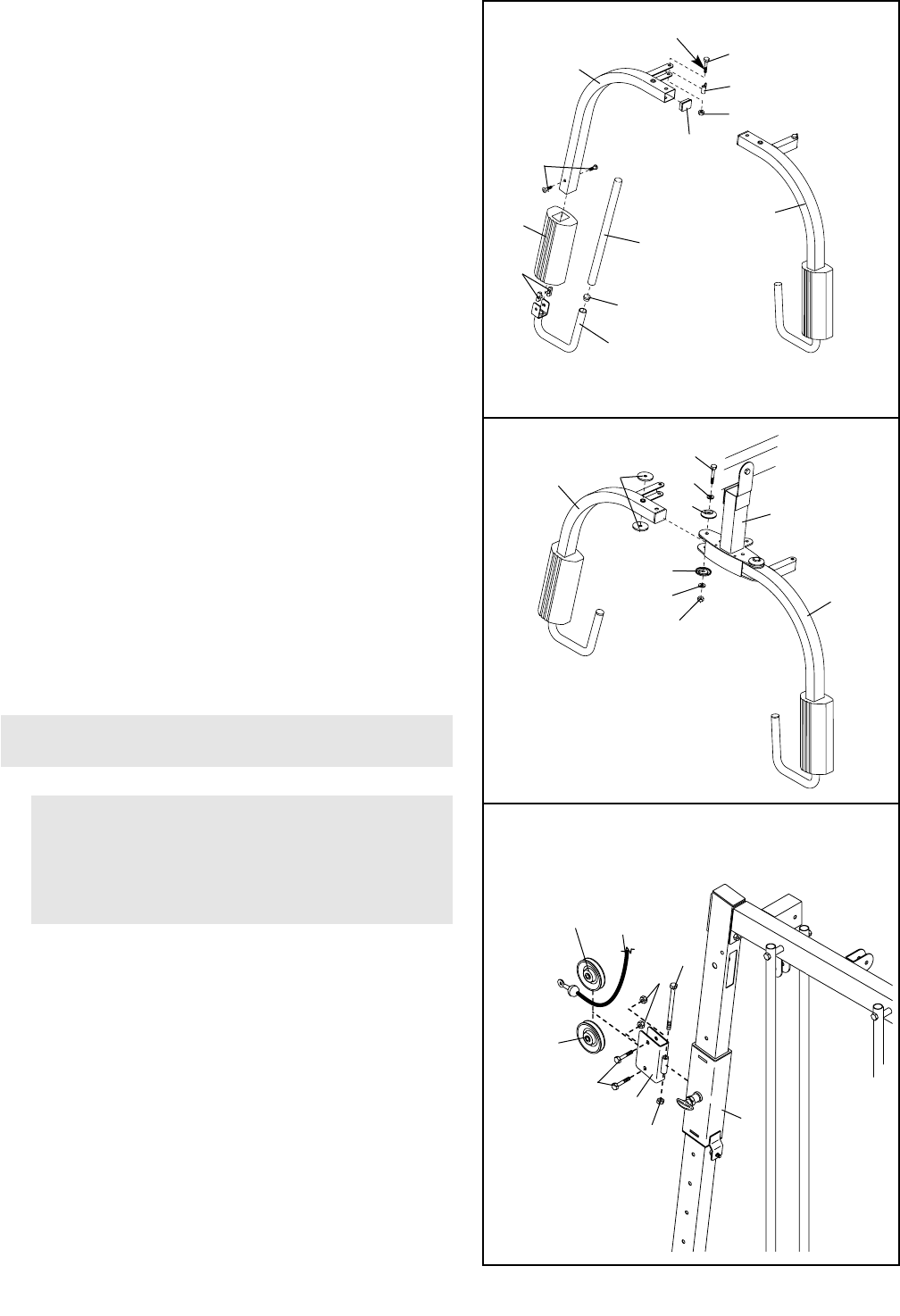

18.

Locate and open the parts bags labeled “CABLE

ASSEMBLY” and “PULLEYS.”

Lubricate the 3/8” x 7” Bolt (30) with grease. Attach

the Swivel Cage (76) to the Swivel Carriage (46)

with the Bolt and a 3/8” Nylon Locknut (87).

Locate the Swivel High Cable (74), which is 126

1/2” long and has a ball on one end and a

threaded bolt on the other end. Wrap the Cable

around a 3 1/2” Pulley (78). Attach two Pulleys to

the Swivel Cage (76) with two 3/8” x 1 3/4” Bolts

(93) and two 3/8” Nylon Locknuts (87).

11

16. Press a 1 1/2” x 2” Inner Cap (21) into the Right

Butterfly Arm (26). Wet the lower end of the Arm with

soapy water. Slide a Long Pad (54) onto the Arm.

Slide two Nut Clips (108) onto a Press Handle (27).

Attach the Press Handle to the Right Butterfly Arm

(26) with two 5/16” x 3/4” Button Head Screws (51).

Slide the Long Pad (54) down so that the bottom is

flush with the lower end of the Arm. Press a 1”

Round Inner Cap (29) into the Press Handle. Wet

the Press Handle with soapy water. Slide a Long

Handgrip (28) onto the Press Handle.

Lubricate a 3/8” x 2” Bolt (100) with grease. Attach

a Pivot Bracket (70) to the Right Butterfly Arm (26)

with the Bolt and a 3/8” Nylon Jamnut (113). Do not

overtighten the Nylon Jamnut; the Pivot Bracket

must be able to pivot easily. Repeat this step

with the Left Butterfly Arm (25).

17. Lubricate a 3/8” x 3” Button Head Bolt (104) and

both sides of two Plastic Washers (56) with grease.

Attach the Right Butterfly Arm (26) to the Butterfly

Frame (47) with the Bolt, the two Plastic Washers,

two Butterfly Caps (57), two 3/8” Washers (91), and

a 3/8” Nylon Jamnut (113) as shown. Make sure

that the recessed sides of the Plastic Washers

are fitted over the welded bushing in the

Butterfly Arm. Do not overtighten the Nylon

Jamnut; the Butterfly Arm must be able to pivot

easily.

Repeat this step with the Left Butterfly Arm (25).

16

CABLE ASSEMBLY

74

18

78

78

87

93

76

87

17

IMPORTANT: Refer to the Cable Identification

Chart on page 26 for help identifying the

cables. Do not overtighten the bolts and

nuts attaching the pulleys. The pulleys must

be able to turn freely.

26

47

113

56

104

91

57

57

91

25

21

100

Lubricate

70

113

26

25

51

29

28

27

54

108

30

46