42

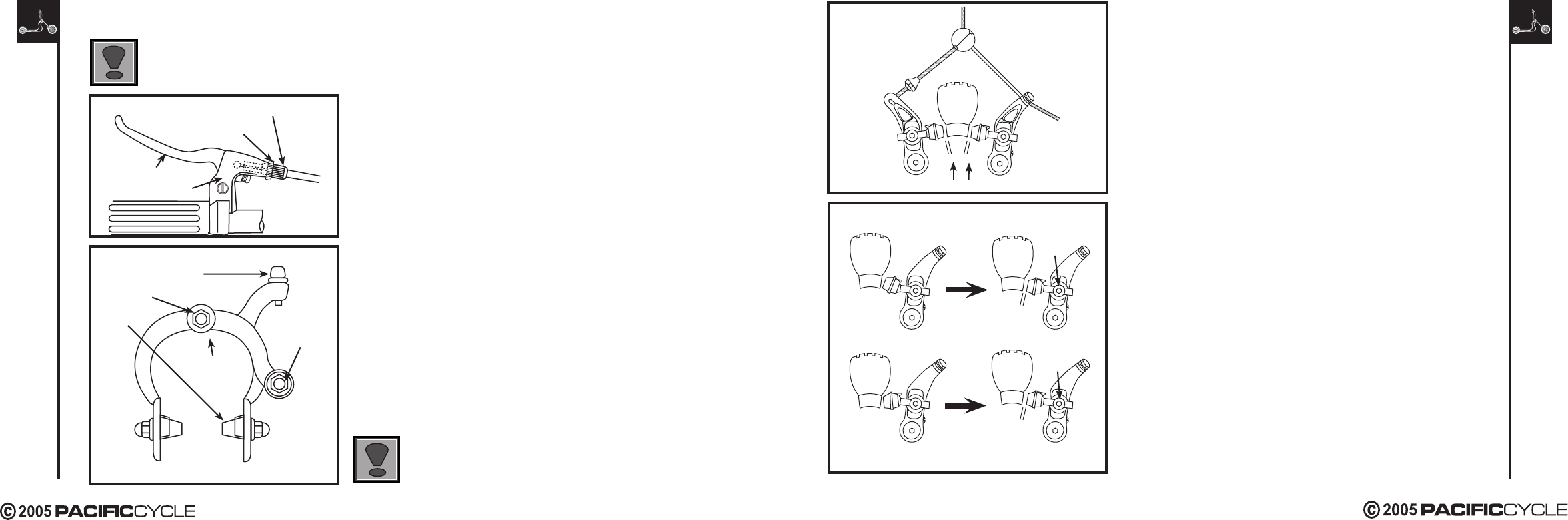

Some brakes have a special mechanism which enables you to set the

clearance on either side of the rim using a screwdriver. Brake pads

should finally be adjusted so that the leading edge of the pad makes

first contact with the rim. Some brakes have special curved washers

to allow this, but on less complex models it will be necessary to apply

a little force to the pad and its mounting.

Adjustment - Cantilever Calipers

Minor brake adjustment can be made via the barrel cable adjusters

which are located on each brake lever. To adjust, squeeze the brake

pads against the rim, loosen the lock nut, and turn the adjuster to pull

the brake pads closer to, or spread them away from the rim as required.

Brake pad clearance should be a maximum 2mm from the rim.

When correct, re-tighten the lock nut. If the pads cannot be set close

enough to the rim in this manner, you may have to adjust either the

length of the straddle cable or the length of the brake cable.

If the brakes use a separate brake cable and straddle cable, adjust

the straddle length by first screwing the barrel adjuster 3/4 of the way

in, then loosening the straddle cable fixing bolt, then pulling or push

ing

the cable through the fixing bolt to adjust the length, and finally

re-tightening the fixing bolt.

Check that the straddle bridge is in the middle of the cable to ensure

even brake pad contact. Apply full force to the brake lever to test,

then fine tune using the barrel adjuster.

To adjust the brake cable length, loosen the brake cable fixing bolt on

the cable straddle bridge, adjust the length until the brake shoes are

the correct distance from the rim, then re-tighten and test.

Parallel

Parallel

Fully Adjustable Brake Shoes

Curved

Adjustment

Washer

Curved

Adjustment

Washer

2mm clearance

41

Some brakes have a quick release mechanism to allow easier wheel removal. Whenever you adjust the brakes,

make sure the quick release mechanism is in the closed position.

Never ride unless the quick release is firmly locked in the closed position.

Lubrication

The brake lever and brake caliper pivot points should be oiled with

2-3 drops of light oil at least every three months to ensure smooth

operation and to reduce wear. Cables should be greased along

their entire length, after removing them from their casings, at least

every six months. Always grease new cables before fitting.

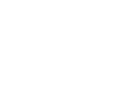

Adjustment - Sidepull Calipers

Minor brake adjustment can be made via the cable adjusting bar-

rel, usually located at the upper cable arm. To adjust, squeeze

the brake pads against the rim, loosen the lock nut and turn the

adjuster Brake pad clearance should be a maximum 2mm from

the rim. When correct, re-tighten the lock nut. If the pads cannot

be set close enough to the rim in this manner, you may have to

adjust the cable length. Screw the barrel adjuster 3/4 of the way in,

squeeze the pads against the rim, undo the cable anchor bolt and

pull the cable through with pliers. Re-tighten the cable anchor bolt

and apply full force to the brake lever to test, then fine tune using

the barrel adjuster. If one pad is closer to the rim than the other,

loosen the fixing nut at the back of the brake, apply the brake to

hold it centered, and re-tighten the fixing nut.

Brake Lever

Brake Lever Housing

Cable Adjusting Barrel

Lock nut

Cable Adjusting Barrel

Center Bolt

Brake Shoe

Side-Pull Brakes

Fixing Nut

in Back

Cable

Anchor

Bolt

Ensure the Brake fixing nut is secured tightly.

Failure to do this may cause the Brake assembly

to dislodge from the fork.