92 / 93

Focusing In order to focus the binocular or spotting scope on an object, optical groups within them have to be shifted with

respect to one another. When focusing is accomplished by moving a lens group inside the instrument, this is referred to as inter-

nal focusing. This enclosed construction and the additional nitrogen filling make it possible to design watertight binoculars and

spotting scopes that guarantee a uniformly high imaging performance that lasts for the entire life of the instrument, even under

the most adverse climatic conditions. The particularly short focusing travel from near to infinity on Leica binoculars (on the Ultra-

vid models it amounts to slightly more than a single turn) the observer can always keep the subject in sharp view very quickly.

Leica HDC™ (High Durable Coating) HDC™ is the proprietary designation of a rub-proof and transmission-enhancing multi-

layer coating process developed by Leica that consists of 7 to 10 exceedingly thin layers, depending on the type of glass to which

they are applied. HDC™ signifies high light transmission combined with high resistance to scratches and environmental effects,

which translates into brilliant images and durability, even in intensive outdoor use.

For the requirements of intensive use in nature, high-performance binoculars and spotting scopes must be able to withstand

extreme mechanical demands over long periods of time. To that end, the optical and mechanical components are mounted in the

body of a Leica binocular or spotting scope in such a way that they cannot shift. The tolerances for the mechanisms used for

moving lens groups are set at a very minimum and they are strictly enforced. An important parameter in the selection of the right

materials is their extreme longevity, and they must also safeguard the highest degree of precision. Leica meets these require-

ments with proven and durable materials such aluminum die-castings and steel. In order to achieve a significant reduction in

weight - for instance in the Ultravid models – Leica also employs special high-tech materials such as magnesium and titanium.

In the planning of all these aspects, the longevity of the products and the benefits for the customers are always in the forefront.

Glossary

Mechanical quality

Leica innovations and patents

The proficiency for innovations at Leica is demonstrated not least by the countless patented problem solutions that are valued by

customers and that evolved in close cooperation and coordination with international innovation teams composed of users in a

great variety of fields.

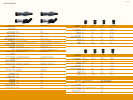

Light transmission, the degree of same When light rays strike on glass

surface, only some of them penetrate the glass, the others are reflected. The

more light penetrates a lens element or an optical system, the higher is their

transmission. As a rule, there is an approximate 4% light reflection at every

glass-/air surface of an uncoated lens. This effect increases exponentially the

more lens elements there are in an optical system (in Leica binoculars there are

up to 11 optical elements = 22 glass-/air surfaces).

Coatings In order to minimize the reflection of light rays, complex procedures

are employed, involving the vapor deposition in high vacuum of numerous

layers of exceedingly thin layers of approximately 0.000125 millimeters, which

corresponds to 1/500 of the thickness of a human hair. At Leica, high-perform-

ance broadband coatings are applied that are tailored specifically to the types

of glass that are being used. Not only do they have the task of elevating the

transmission of an optical system to a close as possible to 100 %, they also

have the important task whenever possible to protect the particularly exposed

external lens surfaces from environmental influences and from damages such

as scratches. These two requirements – high transmission and high environ-

mental- and scratch resistance – are combined in the innovative multi-layer

coating LEICA HDC™.

100 % light

Lens without coating

Lens with Leica HDC™ multi layer coating

approx. 8% reflection

(4% glass-air surface)

92% transmission

100 % light

approx. 0,3% reflection

(0,15% glass-air

surface)

99,7% transmission

Prism systems Prisms have the task of bringing inverted

and laterally reversed images of an object back into the right

position (which is why they are also called reversing systems).

The prisms used in such systems have a decisive influence

on the construction and the compactness of a binocular.

There are two several types of prism systems, such as roof

(left) and porro (right).

Phase correction coating P40 The P40 layer on roof prisms has the task of increasing the sharpness of the image and reducing

disturbing reflections and stray light. Without a P40 coating on the prisms, light sources are rendered with radiating star effects.

With a P40 coating they are reproduced very naturally. In this regard and in direct comparison, the qualitative differences of different

optical brands become obvious very quickly.

Leica HighLux-System HLS™ The HighLux-System HLS™ combines extensive mechani-

cal steps for the reduction of stray light (such as light traps, matte black lacquer, etc.)

and an especially developed mirror layer for prisms into an optimally tailored system.

The HighLux-System HLS™ is used in Duovid and Ultravid binoculars. The highly reflective

dielectrical mirror layer consists of 42 extremely thin individual layers that produce a

degree of reflection of more than 99.5 %. This system makes it possible to increase trans-

mission, contrast and sharpness significantly – the observer gains an extremely bright,

natural pictorial impression with neutral color rendition.

Mirror layer of Leica HighLux-System HLS™