8

SHOCK PUMP

Specialized offers a shock pump (4727-3010), to add or

release air pressure from your Specialized fork. The Fox

shock pump is also recommended. Follow the steps

below:

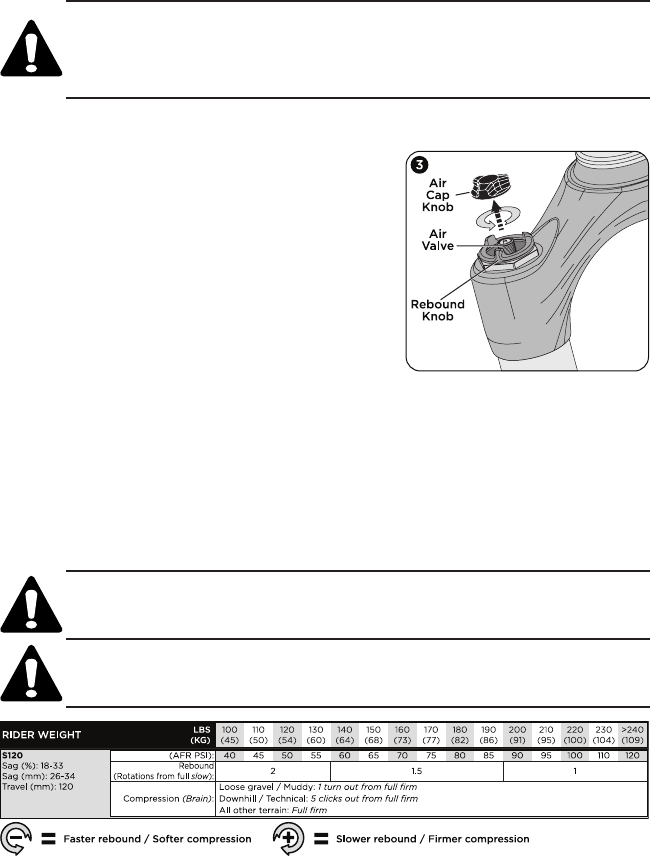

1. Remove the air cap knob from the top of the right

fork leg (Fig.3).

2. Thread the pump’s valve chuck onto the fork’s

schraeder valve (holding the rebound knob so it

won’t turn), until pressure registers on the pump

gauge. Do not over tighten the valve chuck. If

there’s no pressure in the fork, no pressure will

register on the pump gauge.

3. Stroke the pump until you’ve reached the desired pressure (see air chart for pressure

ranges). Pressure can be decreased by depressing the release valve button on the

pump body.

When the valve chuck is removed, air pressure will be released. This air is NOT from

the fork. It’s leftover air from the pump hose. When the pump is reattached to the

valve, pressure in the fork will decrease to fill the pump hose. This will lower pressure

approximately 10 PSI. (i.e. a fork set at 100 PSI will show approximately 90 PSI when the

pump’s hose is re-installed on the fork, as the hose is refilled by pressure in the fork.)

WARNING! Fork pressure range is 40 to 120 PSI. do not exceed 120 PSI.

Exceeding the recommended limit can result in damage to the fork.

WARNING! Avoid lowering pressure too far and bottoming out too often and

too hard, this can result in fork damage.

NOTE: Air pressures and rebound/compression settings are suggested recommendations

only, to provide a starting point for the rider. Adjust for preference / riding style.

Warning! Damage to composite is difficult to visually identify. If the external

composite surface is dented, frayed, gouged, deeply scratched, fractured,

chipped or otherwise damaged, the component should be replaced. If a fork

has suffered a crash or impact, Even if no damage is visible, Specialized or an

authorized Specialized dealer should inspect the product.

6. Adjust the headset to eliminate any free play, make sure that the fork rotates freely.

Align the stem with the fork. Tighten the stem’s upper and lower steerer clamp

bolts in an alternating pattern. Increase torque in 5 in-lbf (0.56 N-m) increments.

Recommended torque applied to the steerer tube is 75 in-lbf (8.5 N-m). Refer to your

stem owner’s manual for specific torque spec recommendations for the stem bolts.