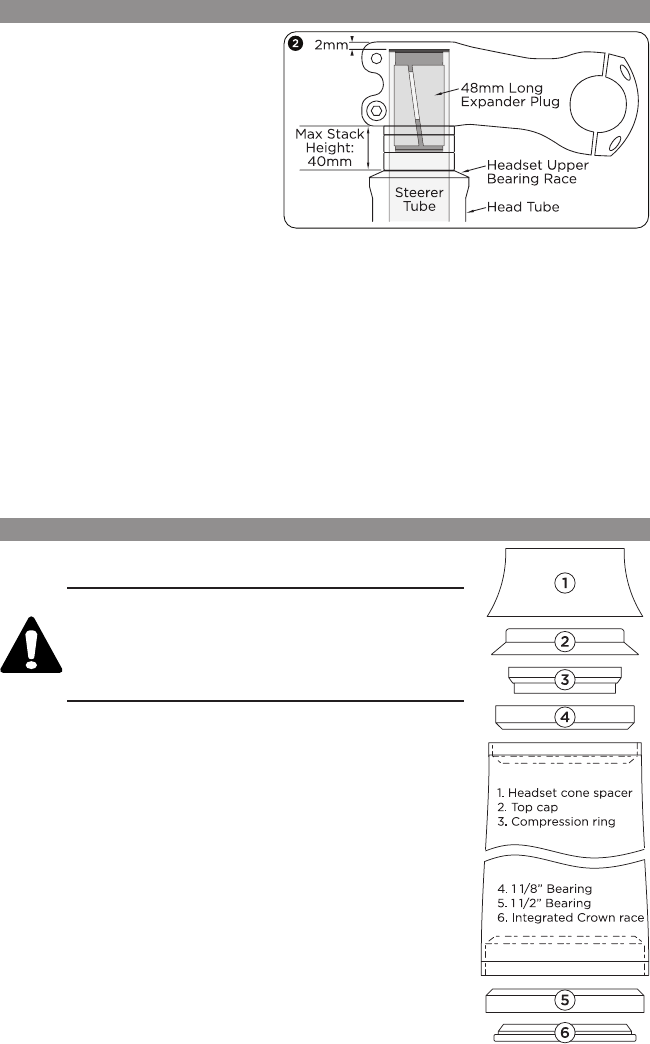

7

1. Once the initial stem height is

achieved, make a mark on the

steerer tube at the top of the stem.

Place the cutting line 3mm below

the mark to allow for the space

needed for the 1mm lip of the

expander plug. The end result is

2mm of space. (Fig. 2)

2. Wrap the area where you intend

to cut the fork with several layers

of masking tape. This will limit

fraying of the fibers, resulting in a cleaner cut. Once you’ve wrapped the layers of

tape, determine the precise location of the desired cut with a pen mark on the tape.

To avoid fraying the composite fibers, it is recommended that a carbide grit toothless

saw blade be used. A fine tooth (36 teeth) saw blade is also acceptable. Double

check all measurements to make sure the steerer tube will not be cut too short. It’s

easier to measure twice than to buy a new fork.

NOTE: It is very important that the steerer tube is cut straight. For best results, use a

steerer tube cutting guide tool.

3. Once the steerer tube is cut to the desired length, remove all burrs at the top of the steerer

tube by rounding out the edge with emery paper or a fine grit sand paper Only sand edge,

not clamping surface! Wipe off all excess dust. Be sure not to breathe carbon dust!

For additional information on carbon fiber preparation, please visit the tech section at

www.specialized.com

CUTTING THE FORK STEERER TUBE

INSTALLING THE FORK

1. Install the 48mm Long Expander Plug (fig.2). Recommended

torque is 100 in-lbf (11.3 N-m).

Warning! The S120 steerer tube requires the use of

the RED (22.5mm O.D.) Specialized 48mm Long

Expander Plug (fig.2) supplied with the fork. Do not

use a star nut, it can damage the inside surface of the

steerer tube. Damage to the steerer tube can result in

failure, causing serious personal injury or death.

2. Place the fork back into the head tube, clean the stem

interface of the steerer tube with isoproyl alcohol.

3. Place the desired amount of headset spacers to achieve

proper stem height, followed by the stem and the top

preload cap.

NOTE: Do not twist the stem onto the steerer tube. This can

result in damage to the surface, which can render the fork

unsafe.

4. Install the disc brake and brake housing guide on the fork. make

sure the brake housing routing doesn’t touch the tire when the

fork is fully compressed and that it doesn’t interfere with the

controls on the handlebar when rotated. Do not overtighten the

bolts, refer to the disc brake manufacturer’s owner’s manual for

recommended torque specifications.

5. Install the front wheel and adjust the brake to allow the

rotor to spin freely.

Fork install steps continued on page 8.