7

q Chain and Sprocket

The chain will typically have a “loose spot” and “tight spot” corresponding with a particular sprocket

rotational position. This is normal and common to all chain driven products due to run-out tolerances of the

freewheel and sprocket. The chain should be adjusted to the ideal tension with chain in the tightest spot.

Proper chain alignment must be maintained. The wheel must not be skewed. If the chain is noisy or rough

running, check the lubrication, tension and alignment of the sprockets, in that order.

WARNING:

To avoid a pinch or injury, keep

fingers away from moving

sprockets and chain.

Need Help? Visit our website for replacement parts, product support and a list of authorized service centers

at www.razor.com or call toll-free at 866-467-2967 Monday - Friday 8:00 AM - 5:00 PM Pacific Time.

REPAIR AND MAINTENANCE

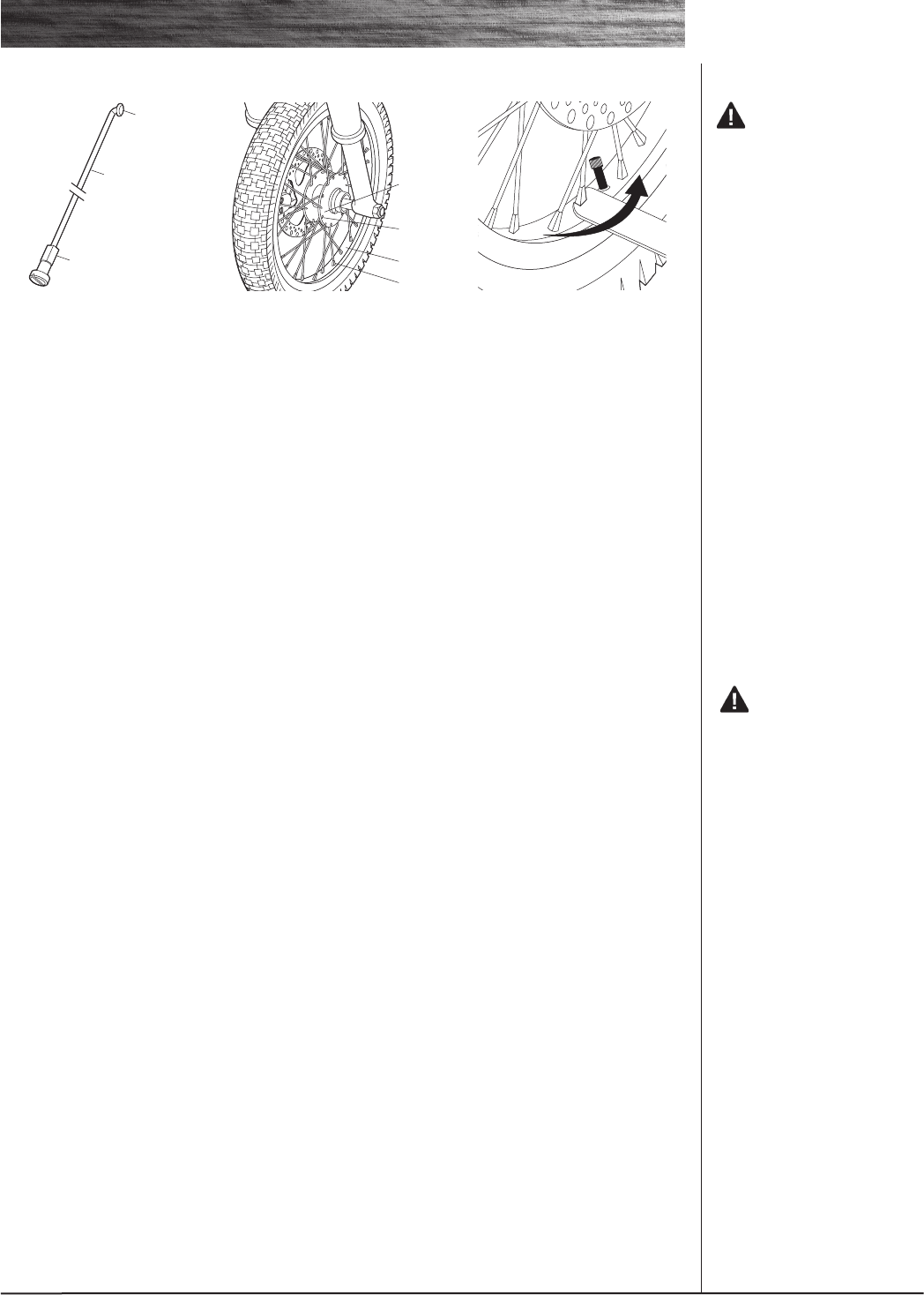

qChecking Spoke Tension

WARNING:

Regularly check the spoke

tension and retighten the

spokes whenever loose. If

you have any doubt, ask an

experienced motorcycle or

bicycle mechanic to inspect

your spokes to determine if

the spokes need tightening or

adjusting.

Spoke

Flange

Spoke

Nipple

Hub

Flange

Spoke

Flange

Rim

Nipple

1

2

3

4

28

27

1 Verify the spoke tension by shaking each spoke with your fingers.

Spoke should not be loose from hub. Look for any play between

where the spoke flanges attach to the hub. Try to turn the nipple us-

ing your fingers. You should not be able to spin any nipple by hand. If

one or more spokes is loose, all spokes must be checked and need to

be tightened with a spoke wrench.

2 Start with spoke closest to the

tire valve stem and tighten each

nipple, in sequence, exactly 1/4

to 1/2 turn. A single 1/4 to 1/2

turn may not be enough to bring

the spokes into proper tension.

Continue tightening all spokes no

more than 1/2 turn in sequence

until all spokes are tight.

Note: More than a 1/2 turn each

can cause the wheel to become

distorted and wobbly thus perma-

nently damaging the wheel.