6

The head amplifier transmits pulses when the sensor is not oscillating (its normal state), and stops

transmitting in the alarm condition when the sensor is oscillating. Thus the normal light on the control

unit indicates a wet Hi-Sens, or dry gap sensors. When the inverting amplifier is used the sensor is in

its quiescent state for most of the time. For this reason sensor cables can be monitored to check for

cable breaks with some sensors.

Note that when an inverse acting head amplifier is used the sensor is not oscillating under normal

conditions and therefore the integrity is not as high as that of a normally acting head amplifier, which

should be used wherever possible.

Inverse acting amplifiers are only available in adjacent mounting industrial housings.

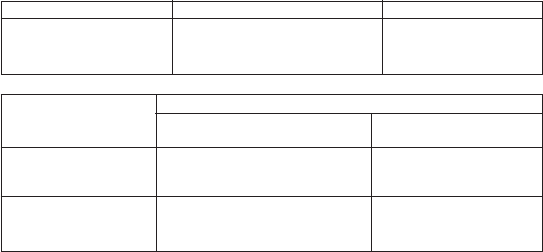

Summary of sensor head amplifiers

Type

Sensor mounting

Adjacent mounting

Inverse acting

Industrial Case

***S*PI***

MEP*AI

MEP*XI

Marine

***S*PM***

-

Sensor State

Hi-Sens Dry

Lo-Sens Wet

Hi-Sens Wet

Lo-Sens Dry

Normally acting head

amplifier *PI*, *PM*, AI

Normal State

Pulses transmitted

Green light on c.u.

Alarm State

No Pulses transmitted

Red light on c.u.

Inverse acting head

amplifier XI

Alarm State

No Pulse transmitted

Red light on c.u.

Normal state

Pulses transmitted

Green light on c.u.

Output

1.1

1.2

Sensor cable check circuitry is built into the industrial adjacent mounted head amplifiers, where the

coaxial cable linking head amplifier and sensor may be exposed on site. This is only operable where

the sensor in use has Earth continuity between the two coaxial cables, see section 2.2 Lack of screen

continuity along these cables causes the head amplifier to signal a fault condition to the control room

readout unit. To use the facility a wire link in the head amplifier must be cut during installation.

(See section 2.2)

1.5 Control Units

The control unit is available in two forms, a free standing plastic case (MEP*L), or a rack mounting

unit (MEP*R). Operation is the same in either case.

Front panel indicators show normal condition (green), alarm (red), and fault (amber). A front panel

switch to test fault and alarm circuits is provided, together with a variable time delay for the alarm

circuit.

Relay contacts are provided to indicate an alarm condition. A second relay is supplied on rack

mounting control units to indicate a fault. On both units, a fault also causes an alarm to be

indicated.

ii) Inverse acting head amplifiers

When it is required to use a Hi-Sens sensor for low level detection, or a Gap Sensor for high level

detection, an inverse acting amplifier must be used. Examples of this are given below:

• Hi-Sens can be used to detect low levels in very light liquids or foams.

• A miniature Gap Sensor 366S, may be used to detect high level when there is insufficient room for

a Hi-Sens.

• High temperature, corrosive, or aerated liquids, where Gap Sensor can be used at high level if

required.