PAGE 9

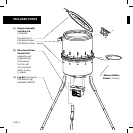

Once a suitable, level location for the feeder is

identified and the unit is properly erected, open

lid and fill container with feed/seed to desired

capacity, never to exceed 150 lbs.

Once done, close the lid and lock the latch securely

to insure it does not come off in the event of high

winds, etc.

This unit is designed to be used primarily with 1/4”

or smaller fish food. This unit is not intended to

be used with a wide variety of other type feeds.

The unit can accommodate other types of feed

but depending on both the brand and type of feed

being used, you may encounter instances whereby

the feed may bridge or clog over the funnel opening

leading to the power control unit. In the event that

this happens, you can clear the bridge manually,

but it is then recommended to use 1/4” or smaller

fish food with this feeder and not alternative of feed

products that may be more affected by moisture.

Each and every feeder design endures a rigorous

field-test routine prior to coming to market, but no

feeder can address all the environmental and feed

type variations. With this being said, consider all the

factors when operating this feeder and be sure to

assess all of your environmental factors thoroughly.

GENERAL SAFETY

Always make sure that the unit is placed on level

ground/surface and is level before you fill the

hopper with any feed. If the unit is not level and

the hopper is full, you run the serious risk of the

unit tipping over and causing harm to both you

and the product itself. Always exercise caution

and care when loading/filling the unit with feed

material. Please make sure that the unit is properly

supported so there is no chance of anyone getting

hurt.

SUGGESTED MAINTENANCE

To insure proper functionality and a long life, BA

Products strongly recommends that you service your

feeder at least once every year.

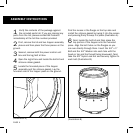

The Model #ADF-150 should have the hopper

thoroughly cleaned out at least once a year. Some

feed types have the tendency to cake and may build

up over time, thus reducing overall hopper capacity,

clogging feed flow or generally interfering with the

overall functionality of the feeder unit.

It is also important to check the bolts located at

the hopper flange regularly to insure that they are

securely tightened and have not come lose. With

prolonged use in the field, animals and other forces

may exert force against the feeder unit which may

cause certain components of the feeder unit to

loosen.

OPERATING INSTRUCTIONS