• Take the Bridge Mount and position it on the seat stay bridge,

centered and aligned with the seat stays.

• Insert one of the motor mount bolts through the bottom hole of the

Bridge Mount and finger-tighten it into the bottom hole of the

Threaded Plate.

MOUNTING MOTOR UNIT

• Slide the slot of the Hinge Bracket (attached to the ZAP Motor

Unit) around the Motor Mount Bolt, between the inside of the seat

stays and the Threaded Plate. Deflating the tire may be necessary

to get the motor in place.

• Finger tighten the remaining motor mount bolt through the Bridge

Mount, and into the Threaded Plate.

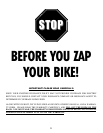

IF YOUR BIKE DOES HAVE THE WELDED PLATE, START HERE

• Insert the motor mount bolts through two of the holes in the weld-

ed bridge plate and finger tighten into the two holes of the

Threaded Plate. (see Fig. 4)

• Slide the slot of the Hinge Bracket (attached to the ZAP Motor

Unit) around the Motor Mount Bolt, between the inside of the seat

stays and the Threaded Plate. Deflating the tire may be necessary

to get the motor in place.

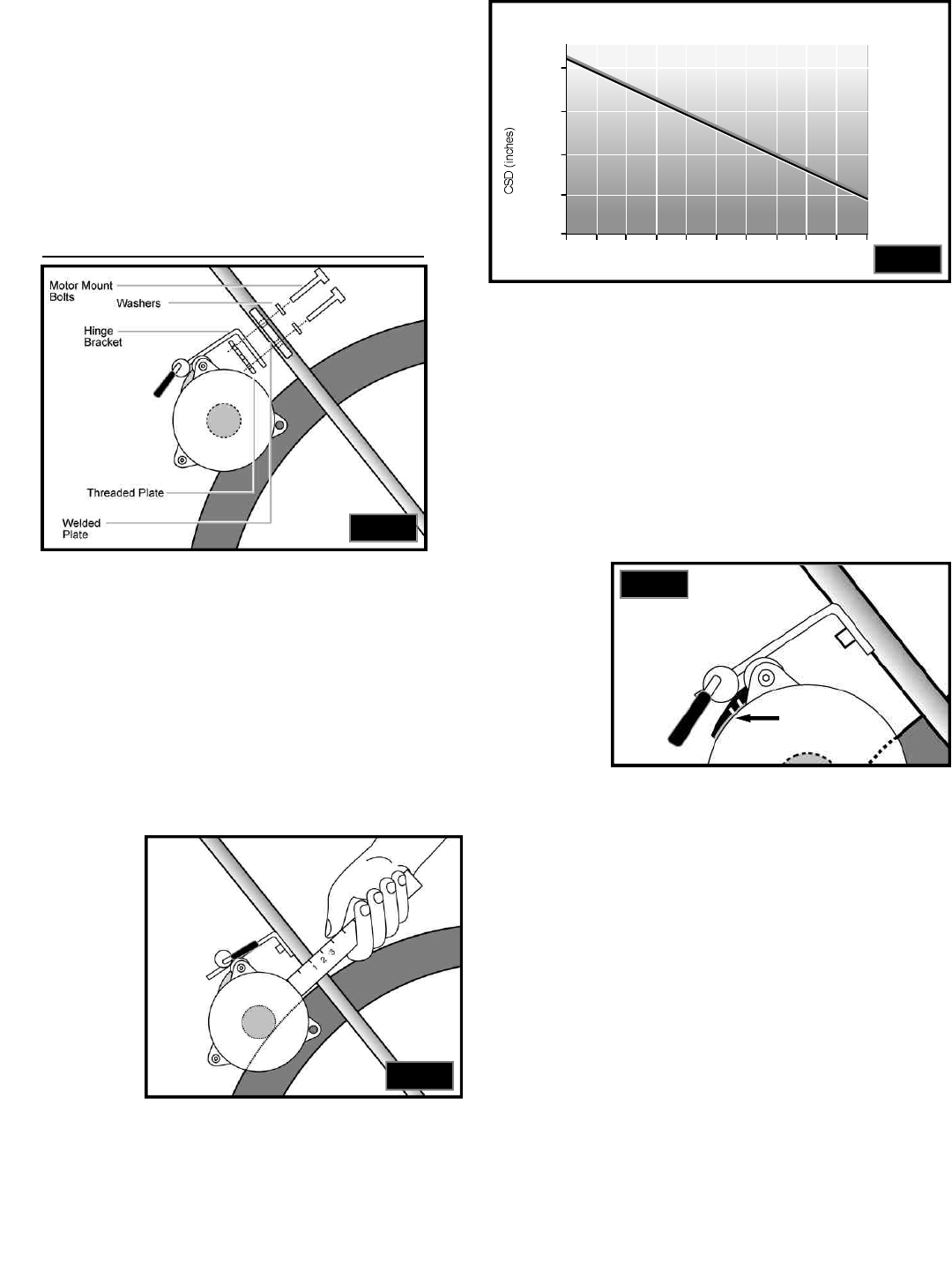

4) Adjusting Motor Unit

• With Cam Lever in the up (disengaged) position, adjust the ZAP

Motor Unit by sliding it up or down along the seat stays until the

proper Critical Set-Up Distance (CSD) is achieved. The CSD is the

distance between the motor and the Seat Stays when the roller is

just touching the tire. (see Fig. 5). Determine the CSD for your bike

by referring to Fig. 6. The recommended pressure for your tires is

printed on the tires.

NOTE: In some

cases (on Cruiser

bikes in particular),

the Standoff (silver

member between

the two motors) will

hit the tire when

the Motor Unit is

pulled in against

the seat stays of

the bike. When

this happens,

adhere the remain-

ing piece of Cam

Ramp on the motor

where it contacts the seat stay. Then, readjust the motor, using the

space between the Seat Stay and the piece of Cam Ramp as the

new CSD.

• Once the CSD is attained, tighten the bolts using the 4mm Allen

Wrench (make sure the ZAP Motor Unit is centered around the tire

and the roller is flat on the tire as opposed to being slanted). Re-

check CSD and correct if needed.

• Put the Cam Lever in the down (engaged) position and notice

how far it forces the Roller into the tire. Ideally, the Cam will force

the Roller about 1/16” into the tire.

• If the Cam forces the roller into the tire more than 1/16”, remove

the Cam Ramp which is adhered to the motor under the Cam using

a flat-head screwdriver or pliers. Engage the Cam Lever, and

check to see if the Cam forces the Roller into the tire the desired

1/16” without a Cam Ramp. If the engagement is less than 1/16”,

take the spare Cam Ramp, which is shorter and slotted, and insert

it where the original Cam Ramp was removed. Check the engage

-

ment once again. If the Roller engagement into the tire is greater

than 1/16”, then snap off the end of the shorter Cam Ramp using

a flathead screwdriver or pliers and check the engagement. One

of these sizes of Cam Ramp will give you approximately 1/16” of

engagement.

• When the correct Cam Ramp size and position is found, cut a

piece of the Double-Sided Tape to match the inside of the Cam

Ramp.

• Peel off one

side of the tape

and adhere it to

the inside of

the Cam Ramp,

without touching

the tacky sur-

face (see Fig. 7).

• Peel off the

other side of the

tape and care-

fully adhere the

Cam Ramp to the motor, under the Cam butted up against the sil

-

ver Spacer Tube.

• Now recheck all critical dimensions:

-Critical Setup Distance

-Roller engagement into the tire when the Cam

Lever is in the down position (1/16”)

NOTE: If you have a bike with a welded bridge plate, you may

have to use different holes in the welded bridge plate (higher or

lower) to achieve proper set-up.

5) Connecting the Motor to the Controller

• Attach the motor / controller lead with the white dot to the motor

lead with the white dot. Plug the other motor / controller lead into

the remaining motor lead (the lead without the white dot.)

6) Connecting Battery Pack

• Push the battery pack assembly into the battery tray.

• Connect battery power connector to controller power connector

(black & red).

• Attach the Velcro on the battery bag flaps to Velcro on the battery

tray and make it tight.

• Run the battery strap underneath the battery tray and through the

“D” ring on the other battery flap and pull tight.

• Fasten the battery strap to itself with the velcro attached to it.

NOTE: Initially, tray is very tight around battery.

ZAP DEFLATES THE TIRES BEFORE PACKAGING THE BIKE

TO PREVENT DAMAGE DURING SHIPPING. INFLATE BOTH

TIRES TO 55 PSI.

Critical Setup Distance (CSD) for

Different Tire Pressures

1/2”

40 45 50 55 60 65 70 75 80 85 90

Tire Pressure (psi)

5/8”

11/16”

9/16”

3/4”

Double

Sided Tape

Fig.5

Fig.6

Fig.7

9

Fig.4