ENGLISH

06

…

DEUTSCH

FRANÇAIS

OWNER’S MANUAL 2007

05

17

For the set up of the front fork please use the fork

specific manual attached to the bike.

We recommend using front forks with a travel of 100mm,

as this will not influence the geometry and alter hand-

ling of the bike.

FRONT FORK SET-UP /

CHANGE OF FRONT FORK

The pivot and bearings on SCOTT Spark are extremely

easy to maintain.

An external treatment with a grease spray after every

bike wash is all you have to do. We do not recommend

heavy grease sprays since these will leave a film on the

parts which is difficult to remove. We recommend the

same for the chain also.

If you have to change the bearings you can order them

included in a service kit at your local SCOTT dealer or

buy them with international parts number as shown

above in the specs list in a hardware store.

In case of a change of the bearings or of the rear swin-

garm you should contact your local SCOTT dealer as you

need special tools for disassembly and assembly

PIVOT MAINTENANCE:

16

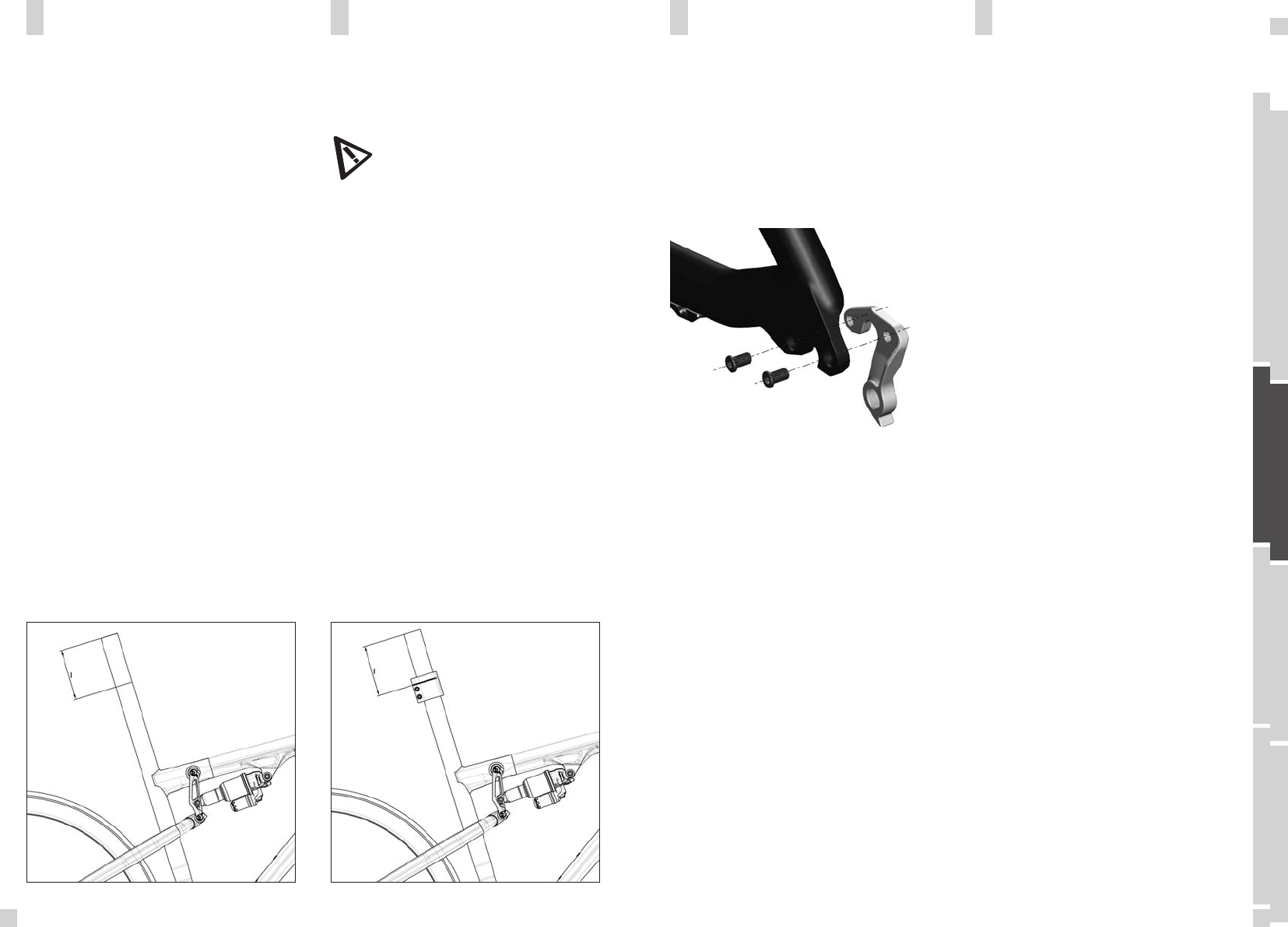

On Spark bikes of model year 07 you can replace the

rear derailleur hanger.

In case the replaceable hanger is damaged by a crash

or accident you can order at your local Scott dealer the

replacement part with Scott article number 206473

REPLACEABLE DROPOUT

6. Take a saw with a blade for cutting metal.

P

l

l

e

e

a

a

s

s

e

e

o

o

n

n

l

l

y

y

u

u

s

s

e

e

a

a

1

1

0

0

D

D

/

/

2

2

4

4

T

T

t

t

e

e

e

e

t

t

h

h

b

b

l

l

a

a

d

d

e

e

t

t

o

o

m

m

a

a

k

k

e

e

s

s

u

u

r

r

e

e

n

n

o

o

t

t

t

t

o

o

d

d

a

a

m

m

a

a

g

g

e

e

t

t

h

h

e

e

c

c

a

a

r

r

b

b

o

o

n

n

t

t

u

u

b

b

e

e

7. Cut the tube, remove the tool and take sandpaper

to smoothen the edges of the cutting area.

8. Remount the seat clamp in its middle adjustment

position (15mm over the top of the seat tube), fix the

2 M5 screws of the seat clamp (4mm Allen key) with

a tightening torque of 5Nm (44 in-lbs)

3. Indicate the length (l) you want to cut on the seat

tube with a marker pen.

4. Slide the Spark Cutting Tool on the seat tube of

Spark until the line of the marker is visible in the slot

on the tool that will guide your saw blade.

5. Fix the two 5mm bolts with a 4mm Allen key with a

tightening torque of 6 Nm (53 in-lbs).