SKU 1102 For technical questions, please call 1-800-444-3353. Page 8

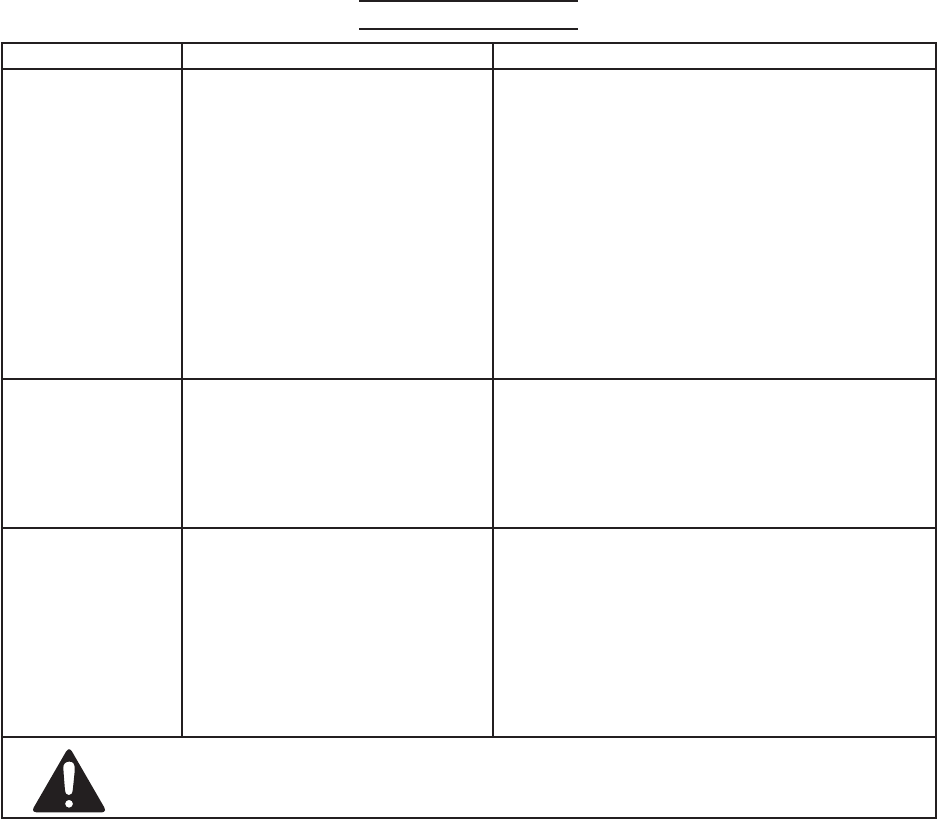

Troubleshooting

Problem Possible Causes Likely Solutions

Spray only “jets”. 1. Can is overlled.

2. Product is too thin.

3. Incorrect air pressure.

4. Button has been blocked.

5. Broken Spray Button.

1. Make sure can is not lled over 50 percent

with liquid.

2. Add product with correct thickness.

3. Make sure air pressure is between 50 and 90

PSI.

4. Clean or replace clogged button.

5. Pry out Spray Button and replace with new

one. Do not insert anything through supply

tube attached to the valve body.

Air bubbles

appear in sprayed

material.

1. Incorrect air pressure.

2. Using incorrect Spray Button.

1. Make sure air pressure is between 50 and 90

PSI.

2. Switch Spray Buttons and apply ner coating

before coating dries.

Severe air

leakage.

1. Cross-threaded Valve Body.

2. Damaged valve or housing.

3. Dirty, worn or damaged

Sealing Gasket.

4. Loose or bad valve core.

1. Back off and reattach.

2. Replace damaged components.

3. Replace Sealing Gasket.

4. Tighten/replace valve core.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.