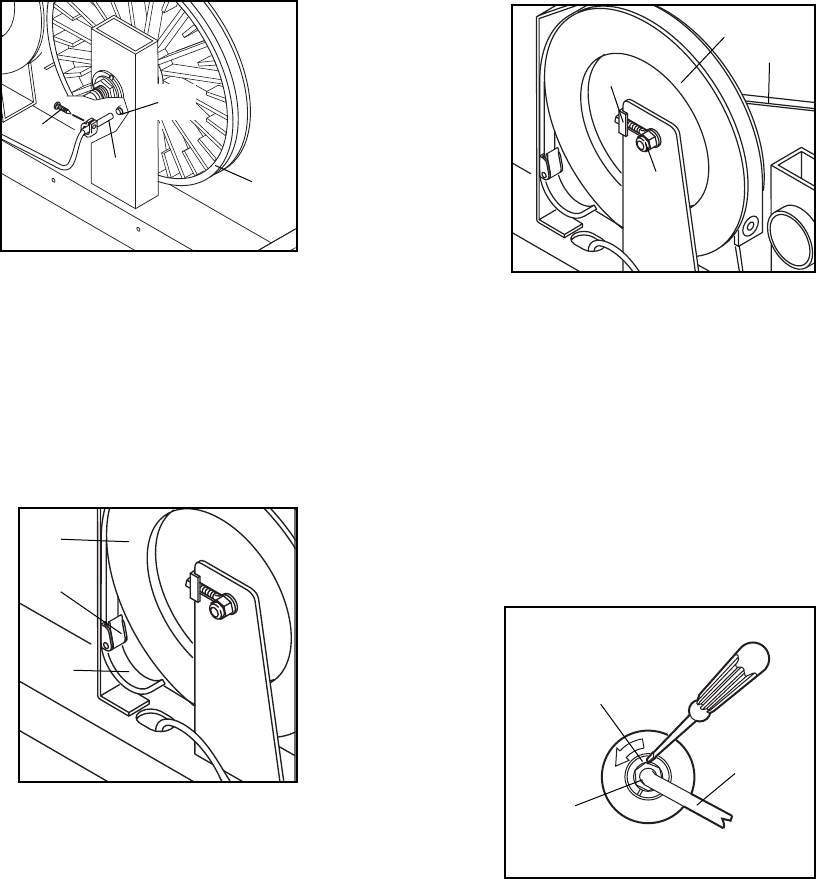

HOW TO ADJUST THE REED SWITCH

If the console does not display correct feedback, the

reed switch should be adjusted. To adjust the reed

switch, the Left Side Shield (11, not shown) must first

be removed as described on page 10.

Next, locate the

Reed Switch

(48). Turn the

Pulley (19) until

the Magnet (55)

is aligned with

the Reed Switch.

Loosen, but do

not remove, the

M4 x 12mm

Screw (51,

shown removed

for clarity). Slide the Reed Switch slightly toward or

away from the Magnet. Make sure that the Magnet will

not hit the Reed Switch. Retighten the Screw. Turn the

Pulley (19) for a moment. Repeat until the console dis-

plays correct feedback. When the Reed Switch is cor-

rectly adjusted, re-attach the left side shield.

HOW TO ADJUST THE RESISTANCE STRAP

If the pedals do

not have enough

resistance, even

when the resis-

tance knob is

turned to the maxi-

mum setting, the

Resistance Strap

(31) may need to

be adjusted. To

adjust the

Resistance Strap,

the Left Side

Shield (11, not shown) must first be removed, as

described on page 10.

Turn the resistance knob to the lowest setting (see

HOW TO ADJUST THE RESISTANCE OF THE

PEDALS on page 9). Open the Buckle (74) and pull

the end of the Resistance Strap (31) slightly down-

ward. Close the Buckle and turn the Flywheel (20) to

make sure that there is not too much resistance.

When the Resistance Strap is properly adjusted, re-

attach the left side shield.

HOW TO ADJUST THE DRIVE BELT

If the Drive Belt (32) slips as you exercise, the Drive

Belt should be adjusted. To adjust the Drive Belt, both

Side Shields (11 and 27, not shown) must first be

removed as described on page 10.

Next, loosen the

two M8 Flange

Nuts (23) (there

is one on each

side of the

Flywheel [20]).

To tighten the

Drive Belt (32),

turn the two M6

Nuts (26) clock-

wise; to loosen

the Drive Belt,

turn the M6 Nuts

counterclockwise. Make sure that the Flywheel is

straight and retighten the M8 Flange Nuts (23). When

the Drive Belt is properly adjusted, re-attach the side

shields.

HOW TO TIGHTEN THE CRANK

If the Crank Arms (10) become loose, they should be

tightened in order to prevent excessive wear. To tight-

en the Crank Arms, the Left Side Shield (11, not

shown) must first be removed as described on page 10.

Next, loosen the

Crank Nut (17)

on the left

Crank Arm (10).

Place the end

of a standard

screwdriver in

one of the slots

in the Slotted

Crank Nut (15).

Lightly tap the

screwdriver with

a hammer to

turn the Slotted Crank Nut counterclockwise until the

arms are no longer loose. Do not overtighten the

Slotted Crank Nut. When the Slotted Crank Nut is

properly tightened, retighten the Crank Nut and re-

attach the left side shield.

11

20

23

26

32

17

15

10

48

55

51

19

20

31

74