123

MAINTENANCE

General Maintenance

EDGE RMKs

1 R emove pressure cap and fill tank to maximum recommended mark.

2 Elevate the front of the machine.

3 Start the engine and run at a fast idle for two to t hree minutes. Air

bubbles should come to the surface of the coolant tank. Run the

machine until air bubbles no longer appear.

4 Shut off the engine and feel for warmth along the tunnel. If the

machine is bled properly, the deicer gripper coolant extrusions will be

warm.

5 If needed, fill coolant to maximum recommended mark.

6 R eplace the pressure cap an d carefully lower the front end of the

machine.

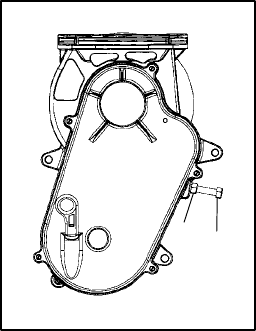

Drive Ch a in Tension

To obtain correct chain tension:

1 Rotate the driven clutch

counterclockwise to move all chain

slack to the tensioner side. Lock the

brake lever lock, or have an a ssistant

hold the brake lever firmly.

2 Loosen the adjuster bolt jam nut (A).

3 Finger tighten the adjuster bolt (B)

until it can no longer be adjusted by

hand, then back off 1/4 turn.

4 Tighten the jam nut while holding

the adjuster bolt.

5 The chain is now tensioned. Release

the brake lever l ock.

A

B